Understanding Deck Floor Roll Forming Machines A Comprehensive Overview

In the construction and building materials industry, efficiency and precision are paramount. One of the key innovations that have transformed the way we produce steel products is the deck floor roll forming machine. This sophisticated piece of machinery is essential for creating high-quality floor decking systems used in commercial and industrial buildings. In this article, we will delve into what deck floor roll forming machines are, how they operate, their applications, and their advantages.

What is a Deck Floor Roll Forming Machine?

A deck floor roll forming machine is a specialized manufacturing device designed to shape metal sheets into specific profiles required for floor decking. These machines work by feeding flat metal sheets—usually galvanized steel or other durable materials—through a series of rollers, which gradually shape the material into the desired profile.

The machine is designed to produce various types of floor decking profiles, such as composite decks, form decks, and metal decks, which are then used to support concrete slabs or serve as standalone flooring solutions. The precision engineering of these machines ensures that each panel produced maintains consistent dimensions and structural integrity.

How Does the Machine Operate?

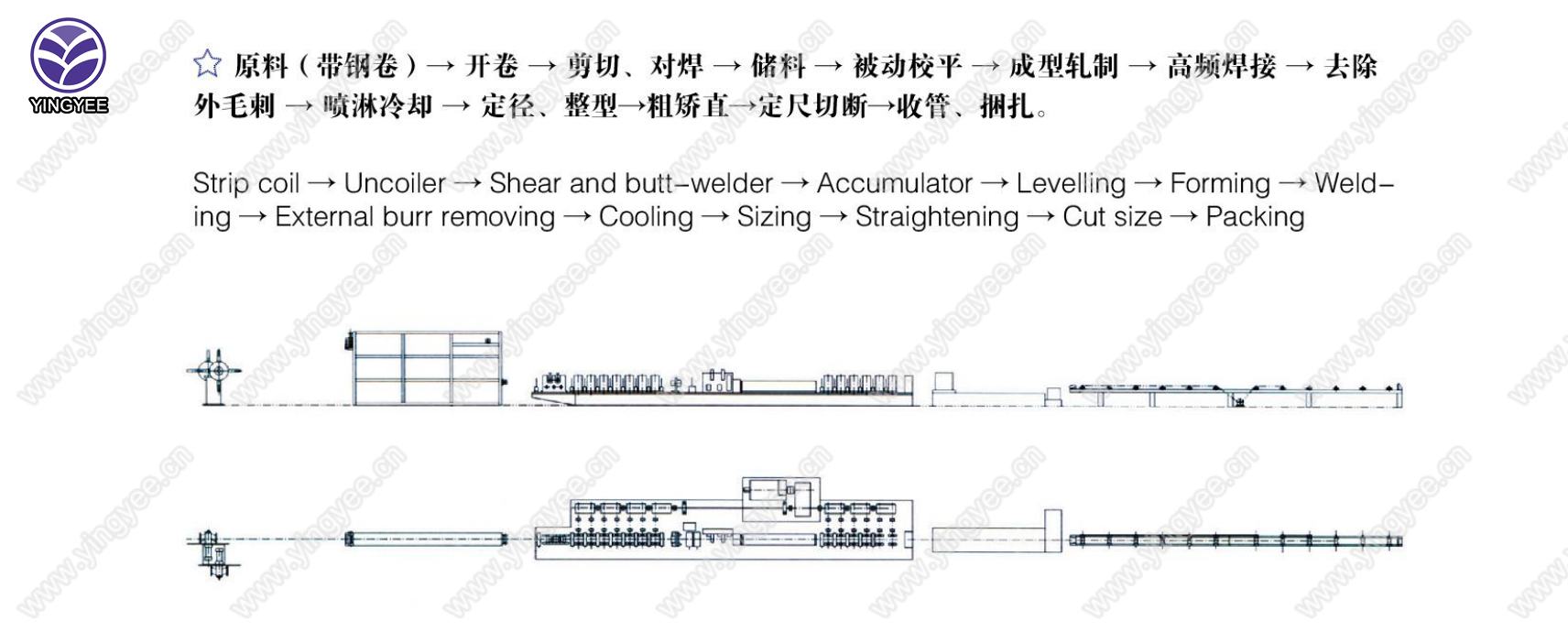

The operation of a deck floor roll forming machine involves several key steps

1. Feeding Flat metal sheets are fed into the machine in a continuous manner. The width and thickness of the sheet can be adjusted based on the specific requirements of the project.

2. Roll Forming As the metal sheet passes through a series of rollers, each roller is designed to bend and shape the metal at specific angles. This process is performed gradually, allowing the material to maintain its structural properties without cracking or deforming.

3. Cutting Once the desired profile is achieved, the machine cuts the panels to the specified length. This can be done using an automated cutting system that ensures precision and efficiency.

4. Stacking Finally, the finished panels are stacked and prepared for packaging or immediate transport to construction sites.

Applications of Deck Floor Roll Forming Machines

Deck floor roll forming machines play a crucial role in various industries, particularly in construction

. Their primary applications include- Commercial Buildings These machines are widely used in the construction of shopping malls, office buildings, and warehouses, where durable flooring systems are required. - Residential Projects In residential construction, they help create strong, composite flooring systems that provide stability and support for multi-story buildings. - Industrial Spaces Factories and manufacturing plants utilize floor decking to create safe and sturdy workspaces that can support significant weight loads.

- Bridges and Infrastructure Decking produced by these machines is also used in bridge constructions and other infrastructural projects where robust flooring is essential.

Advantages of Deck Floor Roll Forming Machines

The use of deck floor roll forming machines presents numerous advantages

1. Efficiency These machines can produce large quantities of decking panels in a relatively short time frame, significantly improving production speed over traditional methods.

2. Precision The automated nature of roll forming allows for high accuracy, ensuring that each panel meets the required specifications without the need for extensive manual labor.

3. Cost-Effective While initial investments in roll forming machinery can be high, the long-term savings in labor and material waste make them a cost-effective solution for manufacturers.

4. Versatility Roll forming machines can be adjusted to produce a wide range of profiles, making them suitable for various projects and material types.

5. Quality The finished products exhibit superior quality, ensuring they meet the rigorous standards required in construction.

Conclusion

Deck floor roll forming machines are indispensable tools in the modern construction industry, enabling the efficient production of high-quality floor decking solutions. Their ability to quickly and accurately produce various profiles not only enhances the construction process but also ensures that safety and durability standards are met. As the demand for innovative building solutions continues to grow, the role of deck floor roll forming machines will undoubtedly become even more critical in shaping the future of construction.