The Evolution of CZU Steel Purlin Roll Forming Machines

In the realm of construction and structural engineering, steel purlins play an essential role in providing exceptional strength and support. Among the various technologies that facilitate the production of high-quality steel purlins, CZU steel purlin roll forming machines have emerged as a preferred choice for manufacturers and builders alike. This article delves into the innovative design, functionality, and applications of CZU steel purlin roll forming machines.

Understanding the CZU Steel Purlin Roll Forming Machine

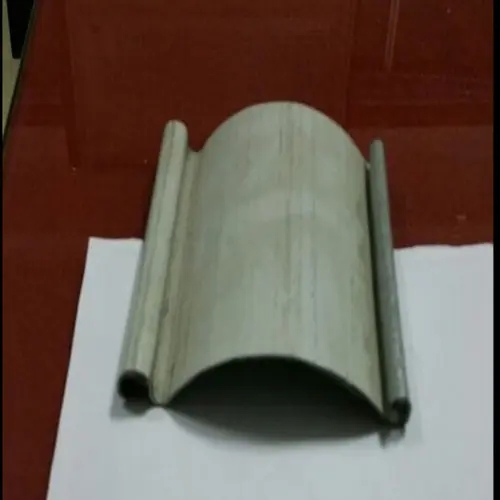

The CZU steel purlin roll forming machine is designed to produce C and Z-shaped steel purlins, which are crucial components in a variety of construction projects. These steel sections are used in the framework of buildings, roof systems, and other structural applications. The roll forming process involves feeding flat steel coils into the machine, which then transforms the material into the desired shape through a series of rollers that continually bend and shape the steel.

The versatility of the CZU machine allows it to produce not only standard purlin sizes but also custom profiles tailored to specific project requirements. This capability is particularly advantageous in a market that increasingly demands precise engineering and flexibility.

Key Features and Benefits

1. Automation and Efficiency Modern CZU steel purlin roll forming machines are equipped with advanced automation features that optimize the manufacturing process. This includes computerized controls that ensure consistent production speeds and precise dimensions. Consequently, manufacturers can achieve higher output levels while minimizing the risk of errors.

2. Material Versatility These machines can process various types of steel, including galvanized steel and other alloys. This flexibility allows manufacturers to meet specific project standards, offering clients a range of options based on strength, weight, and corrosion resistance.

3. Cost-Effectiveness By streamlining the manufacturing process, CZU roll forming machines reduce labor costs and production time. The efficient use of materials also results in minimal waste, further enhancing cost-effectiveness. For companies looking to maximize their profit margins in a competitive industry, this is an invaluable advantage.

4. Quality Consistency The roll forming process ensures that the final product possesses uniform dimensions and strength characteristics. Consistency in quality is paramount for structural components, as it directly impacts the safety and integrity of the entire building.

Applications in Construction

CZU steel purlin roll forming machines are utilized in various construction applications, ranging from residential buildings to large commercial structures. Their primary use is in the creation of purlins that support roofs and walls, providing critical structural integrity. Additionally, these purlins are increasingly being used in pre-engineered buildings (PEBs), where their lightweight nature and ease of installation greatly contribute to project efficiency.

Moreover, the demand for energy-efficient constructions has further amplified the importance of using quality steel purlins. They are often integrated into modern construction practices that emphasize sustainability and resource optimization, aligning with the global push for greener building solutions.

Conclusion

The CZU steel purlin roll forming machine represents a significant advancement in steel fabrication technology. By combining automation, efficiency, and versatility, it allows manufacturers to produce high-quality purlins that meet the evolving demands of the construction industry. As the world continues to embrace innovative building techniques and sustainable practices, the role of CZU steel purlin roll forming machines will likely expand, solidifying their importance in shaping the future of structural engineering. As such, investing in this technology ensures a competitive edge for manufacturers, as well as the reliable and efficient construction of safe and durable buildings.