The Rise of CZU Purlin Machine Manufacturers Innovating Steel Forming Solutions

In recent years, a significant trend has emerged in the construction and manufacturing industries the increased reliance on automated machinery for producing high-quality building materials. Among these machines, the CZU purlin machine has gained notable popularity, providing efficient solutions for the streamlined production of purlins. These specialized machines are essential for creating the structural framework of buildings, particularly in the construction of warehouses, factories, and commercial establishments. This article explores the rise of CZU purlin machine manufacturers, highlighting their innovation and contributions to the industry.

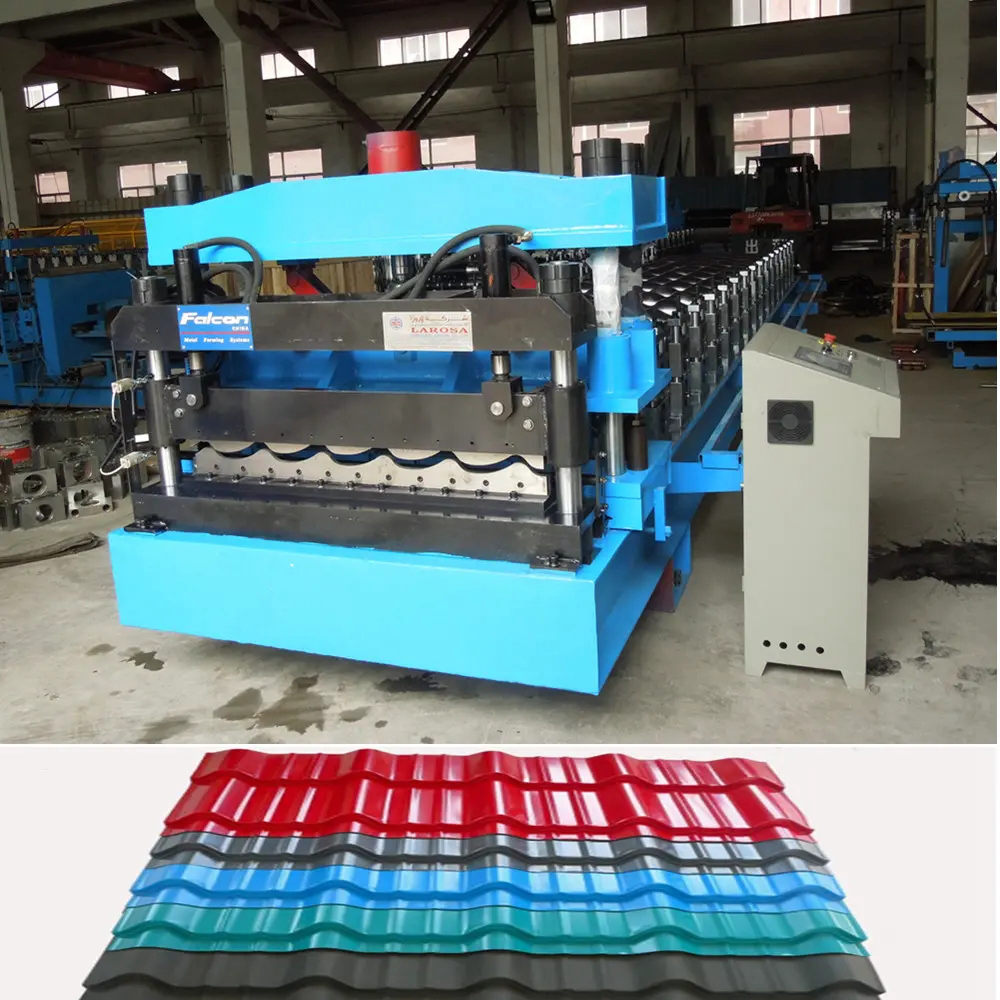

Understanding CZU Purlin Machines

CZU purlins are cold-formed steel sections, often used in the roof and wall support systems of buildings. The CZU purlin machine allows manufacturers to produce these vital components efficiently and in various lengths and sizes, catering to the specific requirements of construction projects. The machine's capability to produce both C and Z-shaped purlins further enhances its versatility, making it an essential tool for modern construction practices.

Innovative Manufacturing Techniques

CZU purlin machine manufacturers are at the forefront of adopting innovative technologies to improve their production capabilities. Advanced computer numerical control (CNC) systems allow for precise and consistent manufacturing of purlins, minimizing waste and maximizing efficiency. Moreover, many manufacturers are integrating Industry 4.0 principles, which emphasize smart manufacturing through automation, data exchange, and machine learning. This transition helps manufacturers not only streamline their processes but also reduce lead times and labor costs.

Customization and Flexibility

One of the key advantages of CZU purlin machines is their ability to customize purlin sizes and shapes based on client specifications. This flexibility is crucial in today’s construction environment, where projects often require unique design elements. Leading manufacturers offer adjustable settings that enable clients to produce purlins of varying heights, widths, and thicknesses. This adaptability not only meets diverse architectural needs but also provides a competitive edge for construction firms that require specific product variations.

Quality Assurance in Production

Quality assurance is paramount in the production of CZU purlins, as these components must withstand various load and environmental conditions. Top manufacturers invest in rigorous testing and quality control measures throughout the manufacturing process. From assessing raw materials to conducting strength tests on finished products, a comprehensive quality management system ensures that the purlins produced meet industry standards and customer expectations. By maintaining high-quality outputs, manufacturers build a strong reputation in a competitive market.

Sustainability Initiatives

As the global demand for sustainable construction practices grows, CZU purlin machine manufacturers are also taking steps to reduce their environmental impact. By employing eco-friendly materials and energy-efficient manufacturing techniques, these companies contribute to a greener future. Furthermore, the efficiency of the purlin production process often results in less material waste compared to traditional methods, aligning with the sustainability goals of many construction projects.

The Global Market Landscape

The market for CZU purlin machines is expanding, spurred by increased urbanization and infrastructure development worldwide. Manufacturers are increasingly exploring international markets, offering their innovative solutions to countries facing rapid construction demands. As global partnerships develop, manufacturers are able to share best practices, enhancing the overall quality and efficiency of purlin production across borders.

Conclusion

The emergence of CZU purlin machine manufacturers represents a significant advancement in the construction industry, reflecting the need for quality, efficiency, and innovation. These manufacturers are not only responding to current market demands but also anticipating future challenges through technology and sustainability initiatives. With a growing emphasis on automated, customizable, and sustainable production processes, CZU purlin machines are likely to play an even larger role in reshaping the future of construction. As the industry evolves, manufacturers will continue to innovate, ensuring that they meet the needs of builders and structures around the globe.