Understanding the CZ Purlin Forming Machine A Key Tool in Modern Construction

In the ever-evolving landscape of construction and manufacturing, efficiency and precision are paramount. One of the unsung heroes of modern structural engineering is the CZ purlin forming machine. This advanced machine is designed to streamline the production of CZ purlins, essential components in steel frame structures. The following article explores the function, benefits, applications, and future prospects of CZ purlin forming machines.

What is a CZ Purlin?

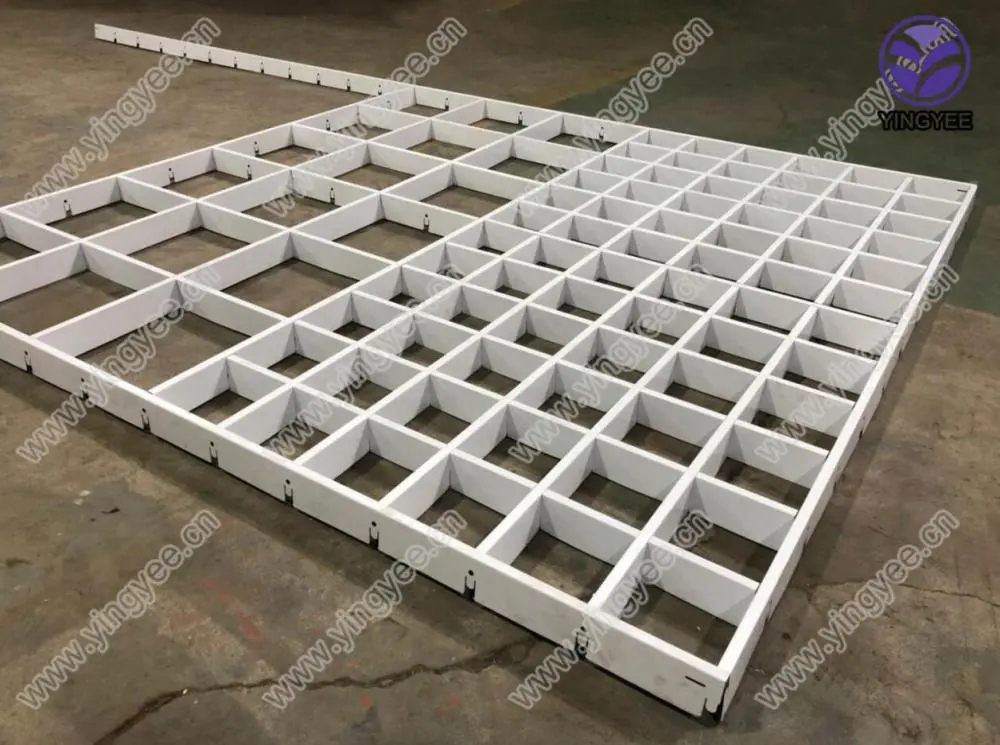

Before delving into the specifics of the forming machine, it's crucial to understand what a CZ purlin is. Purlins are horizontal structural elements used to support roof and wall cladding in buildings. They can be categorized as Z or C profiles, depending on their shape. The C and Z designations refer to the cross-sectional shape of the purlins. C purlins are predominantly used for supporting roof structures, while Z purlins are often used in conjunction with C purlins to enhance load-bearing capabilities. This versatility makes them a preferred choice in various construction projects, from residential buildings to industrial warehouses.

The Role of CZ Purlin Forming Machines

The CZ purlin forming machine is specifically engineered to fabricate these components from metallic coils. The process begins with feeding a coil of steel into the machine, which then shapes and cuts the material into the desired profile—either C or Z—through a series of rollers, punches, and cutting devices. The resulting purlins are manufactured to precise dimensions, ensuring they meet the structural requirements of any given project.

Advantages of Using CZ Purlin Forming Machines

1. Efficiency in Production Traditional methods of purlin fabrication can be time-consuming and labor-intensive. The CZ purlin forming machine automates this process, significantly reducing production time.

2. Cost-Effectiveness By minimizing labor costs and material waste, the use of these machines can lead to substantial savings in project budgets. Additionally, streamlined production allows for faster project turnaround times.

3. High Precision The automation and engineering behind CZ purlin forming machines ensure a high level of precision. This accuracy is crucial in construction, where even minor deviations can impact the structural integrity of a building.

4. Versatility Many CZ purlin forming machines are designed to switch between producing C and Z profiles with little downtime. This flexibility makes them ideal for manufacturers who handle various projects and require adaptability in their production line.

5. Durability and Quality Machines are constructed to high standards, allowing them to produce durable products that can withstand the test of time. This quality assurance is essential in construction, where safety is a primary concern.

Applications of CZ Purlin Forming Machines

CZ purlin forming machines are used across a broad spectrum of industries. These machines are crucial in the construction of

- Commercial Buildings Many retail centers and office buildings utilize purlin frameworks for their roofs and walls. - Industrial Facilities Factories and warehouses commonly employ metal structures supported by purlins for efficiency and strength. - Residential Buildings Modern houses increasingly incorporate purlins in their design for added stability and support. - Agricultural Structures Barns and storage facilities benefit from the strength and lightweight nature of purlins.

Future Prospects

As the construction industry continues to embrace innovative technologies, the demand for CZ purlin forming machines is expected to grow. Manufacturers are exploring advancements in automation, such as incorporating artificial intelligence and Internet of Things (IoT) technology to optimize production cycles and enhance predictive maintenance measures.

Conclusion

In conclusion, the CZ purlin forming machine represents a significant advancement in the field of construction. Its ability to produce high-quality, precision-engineered purlins quickly and cost-effectively has made it an essential tool in building modern frameworks. As technology continues to progress, these machines will undoubtedly play an even more pivotal role in shaping the future of construction and engineering.