The Importance of C-Z Purlin Cold Roll Forming Machines in Modern Construction

In the contemporary construction landscape, efficiency and precision are paramount. One essential innovation that has significantly impacted the building industry is the C-Z purlin cold roll forming machine. This advanced equipment is specially designed to produce C and Z-shaped purlins through a cold roll forming process, which ensures the structural integrity and functionality required in modern construction projects.

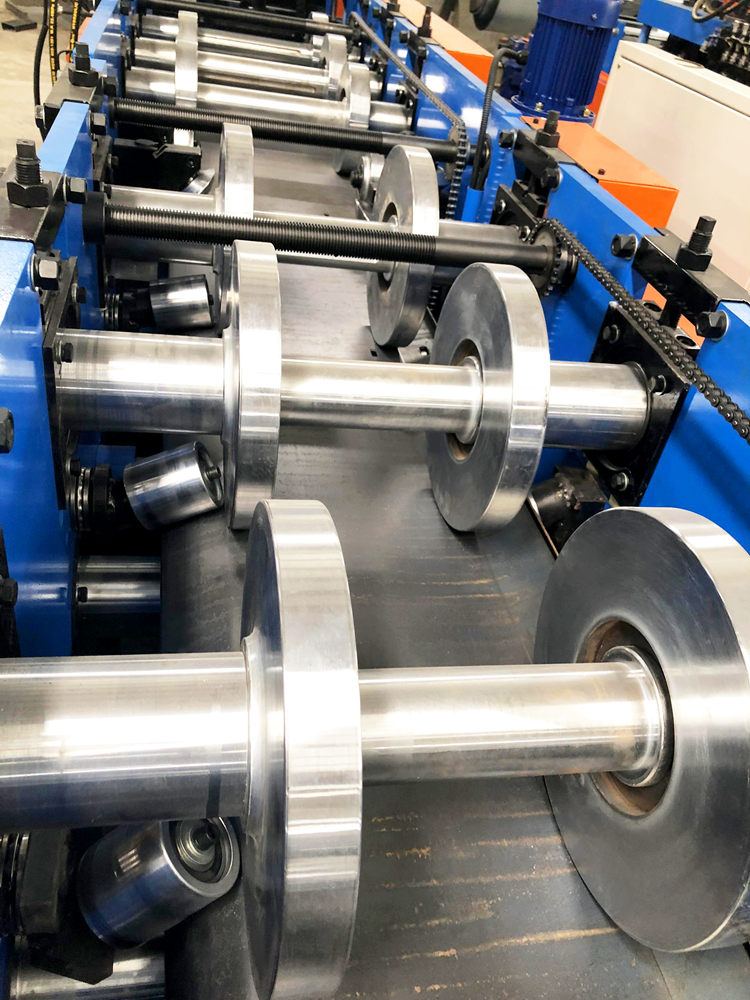

Understanding Cold Roll Forming

Cold roll forming is a process where metal sheets are fed through a series of rollers that gradually shape the material into the desired profile without using heat. This technique allows manufacturers to create components with high precision and minimal waste. The cold roll forming technique is particularly advantageous for producing purlins, which are essential components in the structural framework of buildings.

Purlins serve as horizontal supports for roofing systems, helping to distribute loads and provide stability. C and Z purlins, in particular, are favored due to their strong structural properties and versatility. They can be used in various applications, from light-duty structures to heavier industrial frames.

Benefits of C-Z Purlin Cold Roll Forming Machines

1. High Efficiency C-Z purlin cold roll forming machines are designed for high-speed production. Once set up, they can churn out purlins quickly, significantly reducing the time taken to manufacture these components compared to traditional methods. This efficiency translates into quicker project timelines, helping contractors meet deadlines and reduce labor costs.

2. Precision and Consistency The automated nature of roll forming machines ensures that each purlin produced meets exact specifications. With precision engineering, manufacturers can achieve uniformity in their products, which is crucial for maintaining the structural integrity of the framework in construction projects.

3. Material Savings Cold roll forming minimizes waste by ensuring that any excess material is either recycled or can be minimized in the production process. This not only helps to reduce costs for manufacturers but also supports sustainable practices in the construction industry.

4. Versatility in Design C-Z purlin cold roll forming machines can be adjusted to create various profiles depending on project requirements. This flexibility allows manufacturers to cater to specific customer needs, resulting in custom solutions that fit unique architectural designs.

5. Easy to Transport and Handle The lightweight design of C and Z purlins compared to traditional steel beams makes them easier to transport and handle on-site. This feature is especially beneficial for projects with logistical constraints or when working in remote locations.

Applications in Construction

C-Z purlins are widely used in numerous construction applications. They are commonly found in the framework of warehouses, industrial buildings, and agricultural structures. The adaptability of C-Z purlins means they can also be employed in residential constructions, such as carports or small sheds.

The strength and reliability of C-Z purlins make them a preferred choice for constructing pre-engineered buildings (PEBs), which are becoming increasingly popular due to their cost-effectiveness and time efficiency. As the demand for sustainable construction materials continues to rise, the role of cold roll forming machines in producing eco-friendly, lightweight, and durable purlins will only become more significant.

Future Trends

The construction industry is continually evolving with advancements in technology. The integration of automation and smart manufacturing processes into C-Z purlin cold roll forming machines is expected to enhance production capabilities further. Innovations such as computerized control systems, real-time monitoring, and adaptive technology could revolutionize how purlins are manufactured, improving efficiency and reducing downtime.

In conclusion, C-Z purlin cold roll forming machines play a pivotal role in the modern construction industry by facilitating the efficient production of essential structural components. Their ability to produce high-quality, precisely-engineered purlins not only supports the structural stability of buildings but also aligns with the industry's push towards efficiency and sustainability. With ongoing innovations in technology and manufacturing processes, the significance of these machines is set to grow, making them indispensable in the future of construction.