Navigating the realm of construction materials, particularly in the segment of purlins, requires comprehensive knowledge and dedication to quality and efficiency. C/Z purlin automatic lines have revolutionized the industry with their ability to streamline production processes, enhancing both throughput and precision in manufacturing.

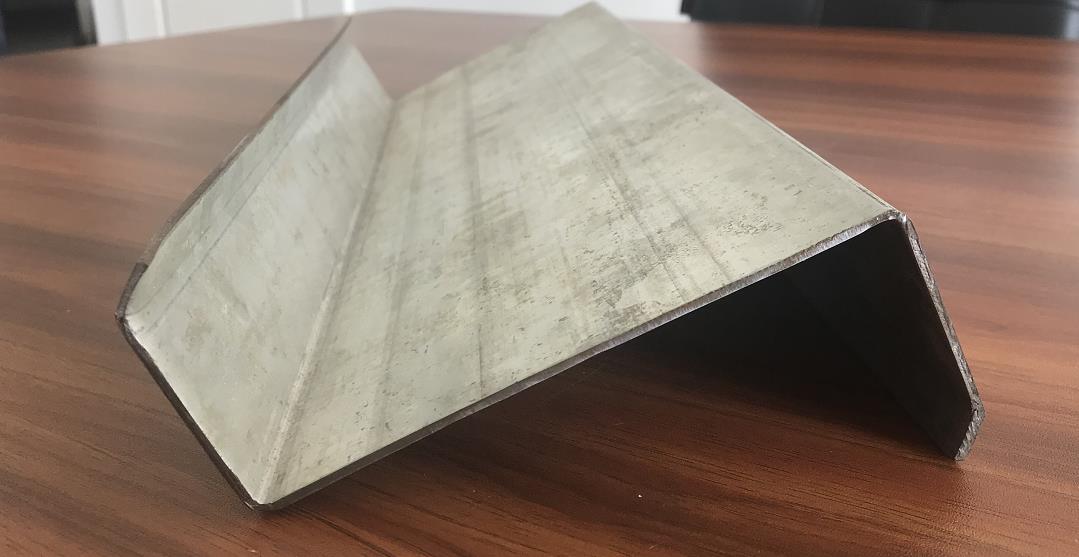

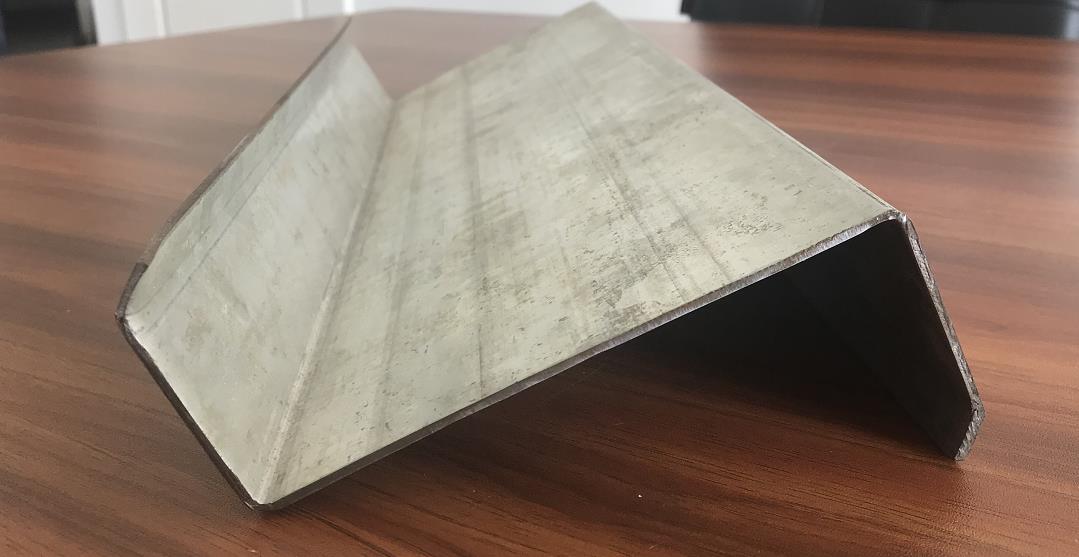

C/Z purlins serve as essential components in building construction, offering high load-bearing capacity with reduced weight. The evolution of their manufacturing techniques, particularly the emergence of automatic lines, has marked a significant leap forward. These automated systems transform raw materials into finished purlins through a seamless process that minimizes waste and maximizes efficiency.

At the heart of a C/Z purlin automatic line lies a series of cutting-edge technologies and equipment meticulously programmed to ensure each purlin meets stringent structural standards. One key feature of these lines is the roll forming machine, an impressive apparatus designed to shape metal sheets into desired profiles through stages of repetitive bending. By using a series of roll stations, the machine ensures precise dimensional accuracy, a vital factor in maintaining the structural integrity of the constructions they will support.

Experience in operating a C/Z purlin automatic line reveals the sophistication embedded in its design. Workers observe the transformation of raw steel coils into robust purlins, appreciating the fine nuances of technology that eliminate manual errors. Complex software controls guide the entire process, offering a user-friendly interface that tailors operations to meet specific production needs. Adjustments in aspects like length and punching patterns can be made swiftly, reflecting the adaptability of the system.

Expertise in using these lines extends beyond mere operation. It involves a deep understanding of material properties and machine maintenance. The automatic line isn't just about enhancing production speed but also about ensuring the highest quality standards. Operators engage in regular calibration of the machinery, ensuring that each output not only adheres to design specifications but also complies with international building codes.

c/z purlin automatic line

Authoritativeness in the field of C/Z purlin manufacturing is enhanced by the integration of automatic lines due to their ability to maintain consistent product quality at scale. Industry leaders who have adopted these lines report not only a reduction in production costs but also significant improvements in product uniformity and strength. The automation reduces the potential for human error, a factor that has traditionally plagued manual manufacturing systems.

Trustworthiness, an often overlooked but crucial aspect, is inherent in automated C/Z purlin lines due to their reliability and traceability. Each purlin produced can be tracked back through the production line, providing accountability at every stage of its manufacture. This capability is particularly important in projects where structural integrity is non-negotiable. Clients receive purlins with documented proof of their compliance with required standards, instilling confidence and cementing trust between supplier and end-user.

Furthermore, the shift towards automation in purlin production coincides with a broader industry trend toward sustainable practices. C/Z purlin automatic lines are reducing material waste through precise cutting and forming techniques, aligning with global efforts to minimize environmental impact. Factories employing these lines experience a reduction in energy consumption and a notable decrease in emissions due to optimized workflows and cutting-edge machinery.

Those involved in the marketing and selling of C/Z purlin automatic lines possess unique insights into their transformative impact on construction projects worldwide. These lines provide value not just through enhanced production capabilities, but also through their contribution to creating safer, more reliable structures. The extensive research and development that back these automated systems reflect a commitment to innovation and excellence, positioning them as a pinnacle of modern engineering solutions.

In conclusion, C/Z purlin automatic lines symbolize an intersection of technology, efficiency, and reliability. The industry’s commitment to experience, expertise, authoritativeness, and trustworthiness manifests through the continued adoption and evolution of these systems. As construction demands grow increasingly complex, these automated lines stand ready to support the industry with unmatched precision and quality.