The Evolution of C/Z Purlin Automatic Lines A Technological Advancement in Construction

In recent years, the construction industry has undergone significant transformations driven by technological advancements. One of the noteworthy innovations is the introduction of automatic lines for producing C and Z purlins, which play a critical role in modern structural steel frameworks. This article delves into the importance of these automatic production lines, their operational efficiency, and their impact on the construction industry.

The Evolution of C/Z Purlin Automatic Lines A Technological Advancement in Construction

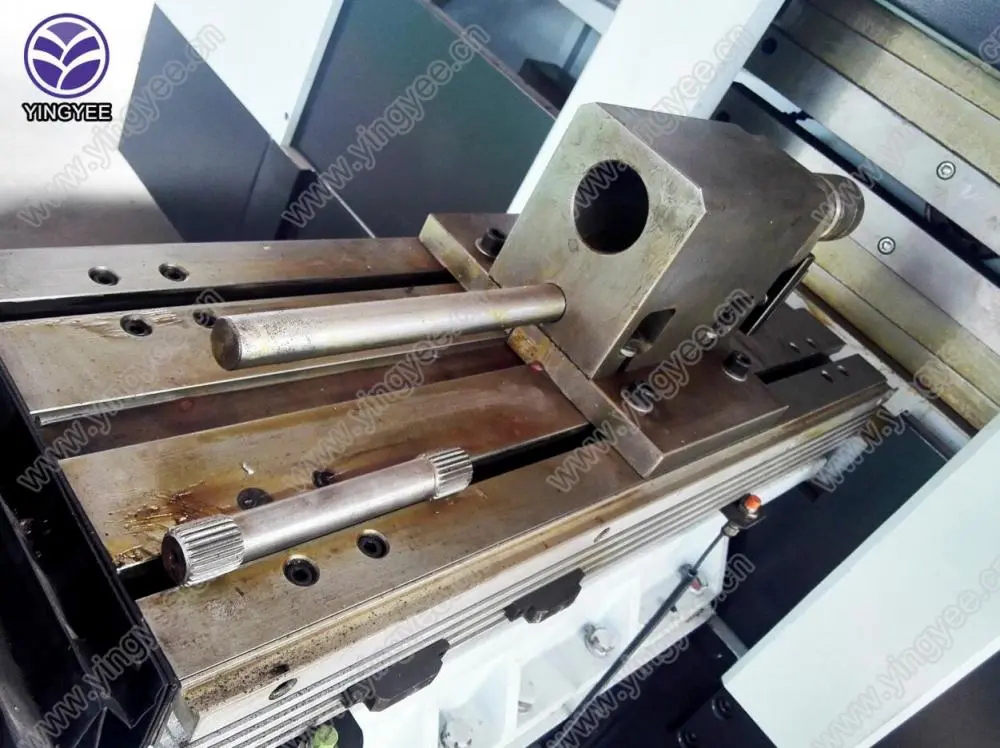

One of the main advantages of C/Z purlin automatic lines is their efficiency. These lines are equipped with advanced machinery that automates the entire production process, from cutting and shaping to welding and assembly. This automation significantly reduces manual labor requirements, allowing for faster production cycles. For example, a traditional setup might take hours to produce a batch of purlins, whereas an automatic line can accomplish the same task in a fraction of the time. This efficiency not only accelerates project timelines but also minimizes labor costs, ultimately resulting in a more economical construction process.

Moreover, the precision offered by automatic production lines is unparalleled. Automated systems utilize sophisticated technology such as Computer Numerical Control (CNC) and laser cutting, which ensure that each purlin is manufactured to exact specifications. This level of accuracy reduces material wastage and enhances overall structural integrity. The consistency achieved in production means that contractors can rely on the quality of the materials they are using, leading to safer constructions and fewer post-installation issues.

In addition to efficiency and precision, automatic lines also promote versatility in product offerings. Many modern C/Z purlin production lines come equipped with customizable features that allow manufacturers to easily adjust dimensions, profiles, and even the types of materials used. This adaptability is crucial in today’s construction environment, where project requirements can vary greatly. Whether it’s a small-scale residential project or a massive industrial complex, manufacturers can cater to specific needs without investing significantly in new equipment.

Furthermore, the shift towards automation reflects a broader trend in the construction industry towards sustainability. Automatic purlin lines are typically designed to optimize material usage, reducing waste in the fabrication process. Additionally, the increased speed of production contributes to lower energy consumption and a reduced carbon footprint. As environmental consciousness rises, builders and manufacturers are increasingly aligned with this trend, making automatic lines a forward-thinking choice.

In conclusion, the development of C/Z purlin automatic lines represents a significant leap forward in construction technology. These systems enhance efficiency, precision, and versatility while promoting sustainable practices within the industry. As construction demands grow and evolve, the reliance on automatic production methods is likely to increase, setting a new standard for quality and efficiency in structural component manufacturing. As we look to the future, the integration of advanced technologies in construction processes will undoubtedly pave the way for safer, faster, and more sustainable building practices.