Cut-to-Length Production Line An Overview

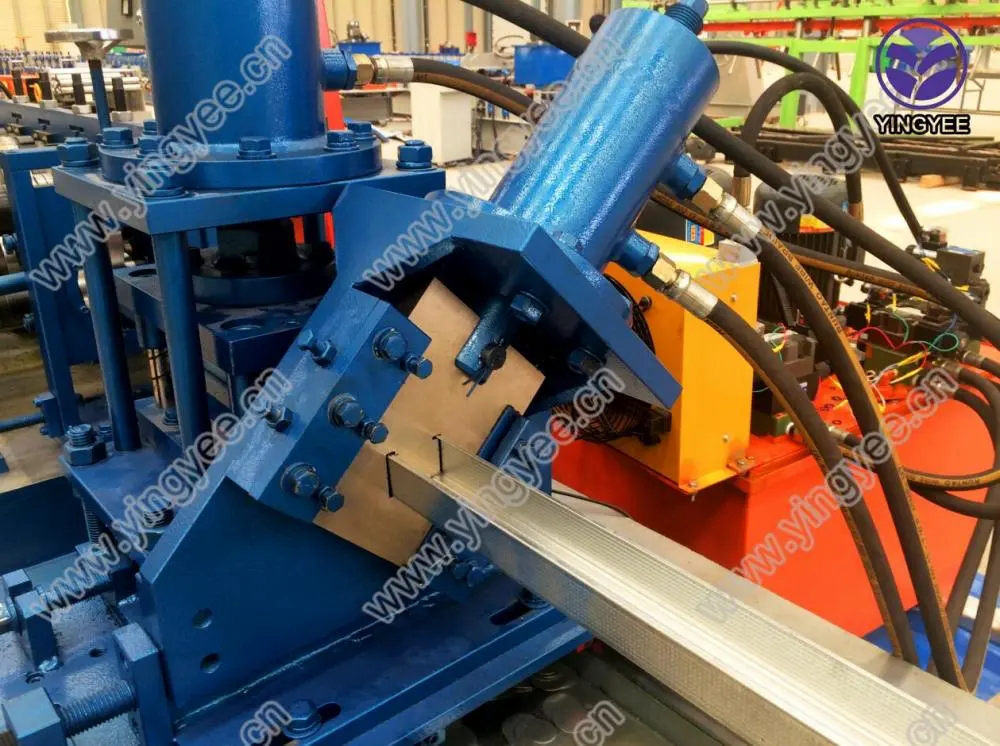

The cut-to-length production line represents a pivotal process in modern manufacturing, particularly in industries dealing with metal, wood, and plastic materials. This system is designed to streamline the production process by efficiently cutting raw materials into predetermined lengths based on specific requirements. As industries continue to evolve, the importance of precision and efficiency in production cannot be overstated, making cut-to-length lines a critical component of many manufacturing operations.

Cut-to-Length Production Line An Overview

One of the key advantages of a cut-to-length production line is its versatility. The system can handle various materials, such as steel coils, aluminum sheets, and even wood panels, allowing manufacturers to adapt to different production needs. Additionally, these lines can be customized to accommodate various thicknesses and widths, further enhancing their applicability across diverse industries. This flexibility is particularly beneficial in today’s fast-paced market, where customer specifications can change rapidly.

Moreover, the cut-to-length process is integral to minimizing waste. By cutting materials to precise lengths, manufacturers can optimize their use of raw materials and reduce off-cuts. This not only contributes to cost savings but also aligns with sustainable manufacturing practices, as less waste translates to a reduced environmental footprint. As organizations increasingly prioritize sustainability, the efficiency offered by cut-to-length lines presents a compelling advantage.

Integrating a cut-to-length production line into an existing manufacturing setup can also lead to significant improvements in workflow. With automated systems in place, the need for extensive manual handling is diminished, thereby allowing workers to focus on more value-added tasks. This boosts employee morale and overall job satisfaction, as workers are less burdened by repetitive and physically demanding tasks.

In conclusion, the cut-to-length production line is a vital component in the landscape of modern manufacturing. Its ability to enhance efficiency, precision, and waste reduction makes it an invaluable tool for companies striving to remain competitive in an ever-evolving market. As technology continues to advance, we can anticipate further innovations within cut-to-length systems, ultimately leading to even greater efficiencies and production capabilities. For manufacturers seeking to optimize their operations, investing in a cut-to-length production line is a strategic move that promises substantial returns.