Understanding the Importance of Cut-to-Length Lines in Modern Manufacturing

In the realm of manufacturing and production, efficiency, precision, and cost-effectiveness are paramount. One method that has gained significant traction in recent years is the cut-to-length line. This process is particularly essential for industries dealing with materials like metal, plastic, wood, and textiles, where the need for tailored sizes and specifications is constant. In this article, we will explore what cut-to-length lines are, their benefits, and how they fit into the broader context of modern manufacturing.

What is a Cut-to-Length Line?

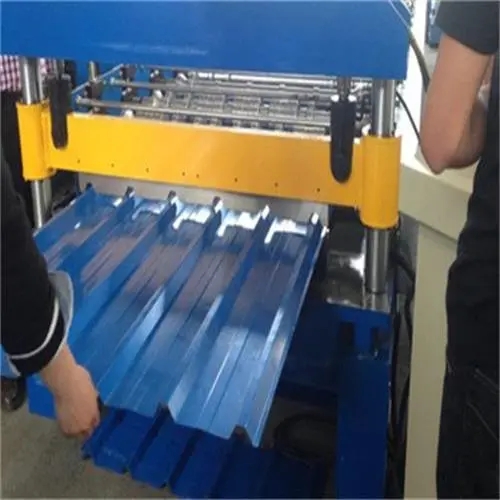

A cut-to-length line is a production system designed to cut large rolls or sheets of material into specific lengths without producing scrap. The process typically involves automation, utilizing specialized machinery that can precisely measure and cut material according to predetermined specifications. This can include everything from tubes and bars to sheets of material. The equipment often integrates conveyors, cutting tools, and control systems that can optimize the cutting process for speed and accuracy.

Benefits of Cut-to-Length Lines

1. Customization One of the primary advantages of a cut-to-length line is the ability to produce custom sizes. Many industries require materials that meet unique dimensions or specifications. A cut-to-length line allows manufacturers to quickly adjust to these requirements without extensive downtime.

2. Material Efficiency By cutting materials to exact lengths, manufacturers can significantly reduce waste. Traditional methods of cutting often resulted in excess scrap, leading to higher costs and less environmentally friendly practices. Cut-to-length lines ensure that materials are utilized more efficiently, making the production process more sustainable.

3. Speed and Automation Modern cut-to-length lines are predominantly automated, resulting in faster production times. Automation reduces the potential for human error and enhances consistency and quality across products. With the integration of advanced technology, such as sensors and software optimization, manufacturers can achieve high-speed operations without sacrificing accuracy.

4. Cost-Effectiveness Although the initial investment in a cut-to-length line may be considerable, the long-term savings can be significant. By reducing scrap, improving speed, and enabling customization, manufacturers can lower operational costs and improve their profit margins. This is particularly crucial in competitive markets where margins are tight.

5. Enhanced Quality Control The use of automated systems in cut-to-length lines also facilitates better quality control. Sensors can detect deviations in the cutting process and alert operators immediately. This ensures that all products meet the required specifications, which can improve customer satisfaction and reduce returns.

Applications of Cut-to-Length Lines

Cut-to-length lines are versatile and serve a variety of industries. In the metalworking industry, for instance, they are used to cut sheets and coils of steel to customer specifications for construction or manufacturing projects. Similarly, in the woodworking sector, these lines can process lumber quickly and efficiently, tailoring lengths for furniture production or building materials.

Textile industries also benefit from cut-to-length lines. Fabrics can be cut to specific lengths for fashion, upholstery, or industrial applications, helping to streamline inventory management and reduce excess material.

The Future of Cut-to-Length Lines

As industries continue to evolve, the importance of cut-to-length lines is expected to grow. The advent of Industry 4.0, characterized by smart manufacturing and the Internet of Things (IoT), promises to further enhance these systems. Real-time data analytics can optimize cutting processes, predict maintenance needs, and improve overall efficiency.

In conclusion, cut-to-length lines play a crucial role in modern manufacturing, allowing companies to meet the demands of customized production while minimizing waste and maximizing efficiency. As technology continues to advance, these systems will undoubtedly become even more integral to achieving operational excellence across various industries. Embracing the capabilities of cut-to-length lines is not just a choice; it is becoming a necessity for manufacturers aiming to stay competitive in an ever-evolving market landscape.