The Cut-to-Length Line Machine Revolutionizing Metal Processing

In the manufacturing industry, efficiency and precision are paramount. Among the diverse machinery used in processing metals, the cut-to-length line machine stands out as a critical player. This machine is designed to cut large metal coils or sheets into specified lengths, facilitating the production of uniform pieces suitable for various applications.

Functionality and Features

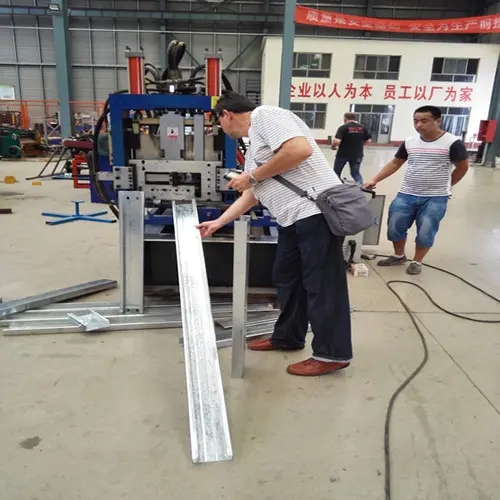

The cut-to-length line machine operates by taking large rolls of metal, known as coils, and feeding them through a series of rollers and cutting tools. The process typically begins with uncoiling the material, followed by leveling it to ensure a flat surface. This leveling process is crucial as it eliminates any distortions caused during the coiling phase.

After leveling, the material moves towards the cutting section, where it is precisely cut to the desired lengths using either rotary shears or guillotine cutters. Advanced models of cut-to-length line machines are equipped with automation technology that allows for quick adjustments to cutting lengths, offering flexibility to accommodate different production requirements without significant downtime.

Advantages of Cut-to-Length Line Machines

One of the primary advantages of using a cut-to-length line machine is enhanced efficiency. Traditional methods of cutting metal sheets often involve manual labor, leading to inconsistencies in size and quality. The automated nature of cut-to-length machines ensures that each piece is cut accurately, minimizing waste and maximizing material utilization.

Moreover, the speed at which these machines operate can dramatically increase production rates. A cut-to-length line machine can process several meters of material within a short time frame, thus boosting overall output while maintaining high standards of precision.

Another significant benefit lies in the variety of materials that these machines can handle. From stainless steel and aluminum to copper and brass, cut-to-length line machines are versatile enough to accommodate different alloys, making them essential for industries like automotive, aerospace, and construction.

Industry Applications

The applications of cut-to-length line machines are extensive. In the automotive industry, for example, they are used to produce components such as body panels and chassis parts. Similarly, in construction, these machines provide steel and aluminum sheets of precise dimensions for use in structural applications.

Additionally, manufacturers of appliances and electronic equipment rely on cut-to-length lines to deliver high-quality metal parts that meet stringent specifications. The importance of accuracy in these industries cannot be overstated, and the cut-to-length line machine plays a pivotal role in achieving the desired results.

Conclusion

In summary, the cut-to-length line machine has revolutionized the way metal processing is conducted across various industries. By automating the cutting process, these machines have increased efficiency, reduced waste, and ensured precision in the fabrication of metal components. As technology continues to advance, we can expect further innovations in cut-to-length machinery, enhancing capabilities and efficiency in the ever-evolving landscape of manufacturing.