Customized Angle Stud and Track Manufacturing The Future of Construction with Roll Forming Technology

In the ever-evolving construction industry, the demand for customized building materials is on the rise. One of the most critical innovations in this area is the development of customized angle studs and tracks, which are integral components in various architectural applications. This article delves into the significance of customized solutions and the role of wall angle roll forming machines in revolutionizing construction techniques.

Angle studs and tracks are pivotal in constructing walls, ceilings, and other structural frameworks. Their versatility allows for the creation of robust and reliable support systems tailored to specific project requirements. Traditionally, manufacturers produced standard sizes and shapes, which often led to inefficiencies and waste. However, with advancements in roll forming technology, companies can now produce customized angle studs and tracks with exceptional precision and speed.

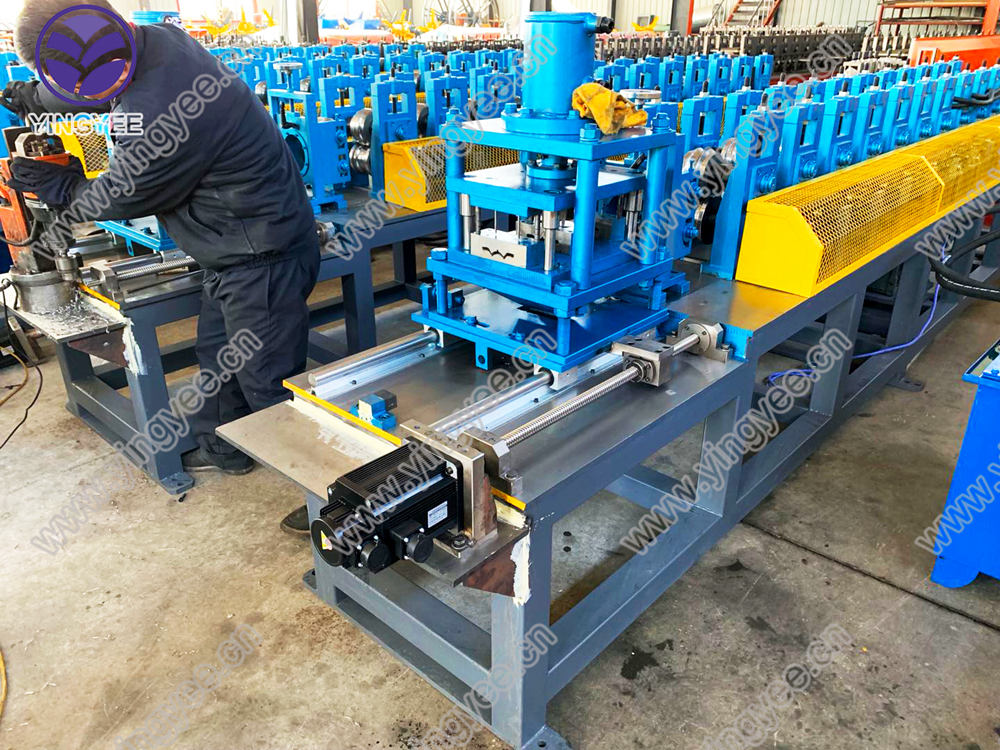

Roll forming machines, particularly those designed for producing C channels and main channels, have become game-changers in the manufacturing process. These machines utilize a continuous bending process to shape metal sheets into desired profiles, such as C channels that serve as the backbone of wall structures. The ability to customize angles and sizes on demand enables builders and contractors to optimize material usage, thus minimizing costs and reducing environmental impact.

One of the key advantages of using automated roll forming machines is their efficiency. Unlike traditional methods, which may require extensive manual labor and time-consuming processes, roll forming machines operate with remarkable speed and consistent quality. This not only accelerates production times but also ensures that every piece meets quality standards, leading to fewer defects and reduced rework.

Furthermore, the integration of digital design software with roll forming equipment allows manufacturers to easily manipulate designs and specifications based on customer needs

. This flexibility means that projects with unique architectural elements or unusual dimensions can be accommodated without the lengthy lead times typical of conventional manufacturing methods.The implementation of customized angle studs and tracks through advanced roll forming technology also contributes to improved structural integrity. Properly designed and manufactured components ensure that buildings are safe, stable, and capable of withstanding various stresses. This is particularly important in regions prone to natural disasters, where the choice of materials can significantly affect the overall resilience of a structure.

In conclusion, the emergence of customized angle studs and tracks, facilitated by wall angle roll forming machines, marks a pivotal advancement in the construction industry. As building designs become more innovative and the demand for tailored solutions increases, these technologies will play a crucial role in streamlining construction processes and enhancing structural performance. The future of building materials lies in customization, and roll forming technology is at the forefront of this transformation.