In the rapidly advancing world of construction and architecture, the need for precision, efficiency, and versatility has never been more critical.

Enter the curving Unistrut roll forming machine, a cutting-edge tool that brings a revolution to structural support systems. The unique ability of this machine to carefully curve and shape metal struts to precise specifications makes it an essential asset in modern building projects.

Traditionally, constructing with Unistrut systems required labor-intensive processes that included cutting, welding, and manual adjustment of metal struts. The introduction of the curving Unistrut roll forming machine has streamlined these tasks by integrating technology with human expertise to produce high-quality products rapidly and efficiently. This machine operates with astonishing precision, ensuring that each piece formed is consistent with the design requirements, reducing errors, and minimizing waste significantly.

Professionals who have employed the curving Unistrut roll forming machine often emphasize its capacity to enhance productivity. By automating the usually meticulous process of bending and shaping struts, it allows builders to focus on other critical areas of construction. The machine supports a range of designs, enabling the creation of complex architectural structures that were once thought challenging or too costly. This flexibility not only broadens the scope of structural possibilities but does so without compromising on the integrity or strength of the materials used.

A significant advantage of this technology is its integration with digital design software. Engineers and architects can input detailed specifications into the system, which the curving Unistrut roll forming machine interprets accurately. This capability translates directly into enhanced precision on construction sites, as what is planned on a screen can be reliably reproduced in physical form. The reliance on meticulous planning and precise execution offers an assurance of safety and performance, critical metrics in structural engineering.

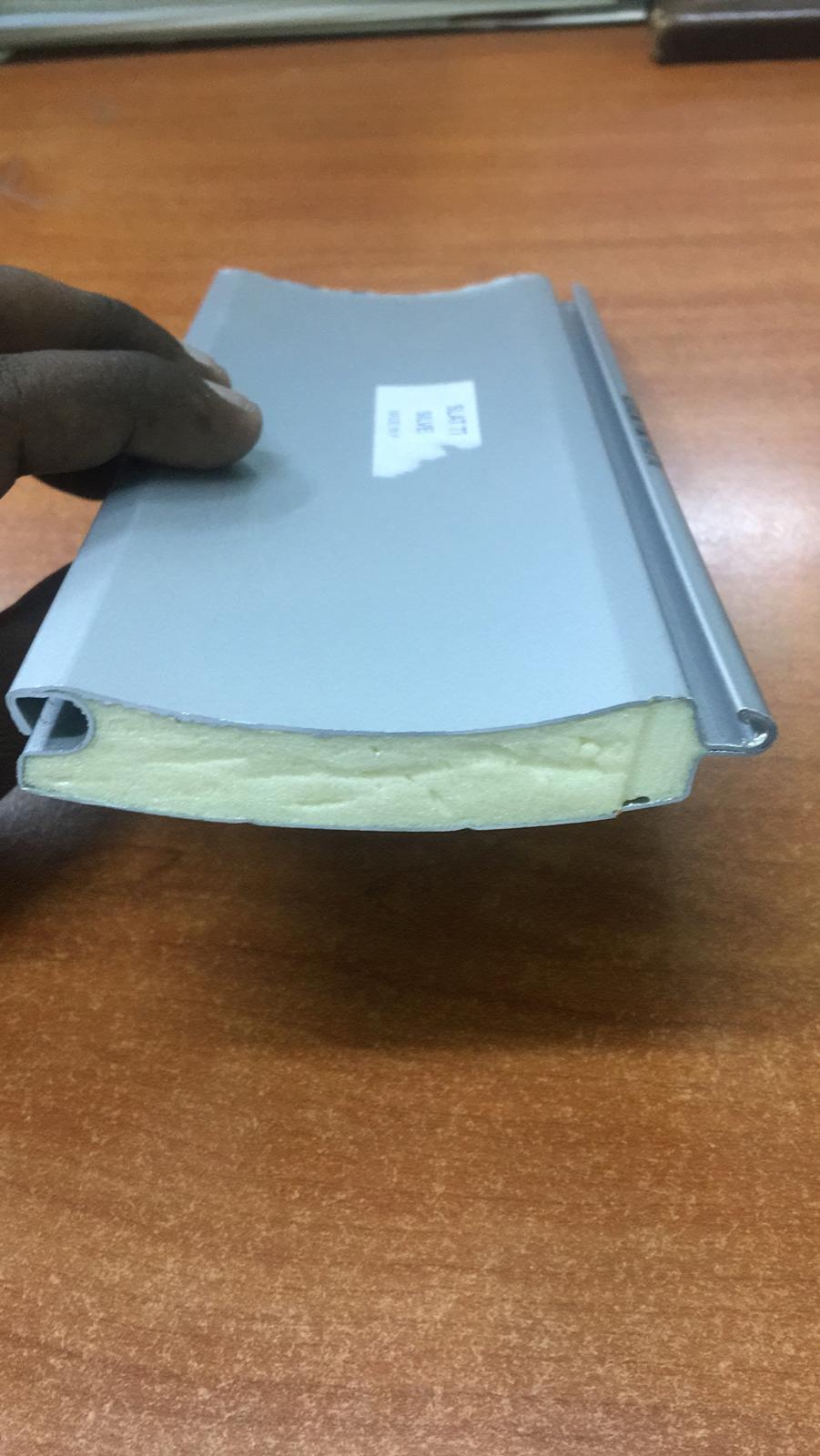

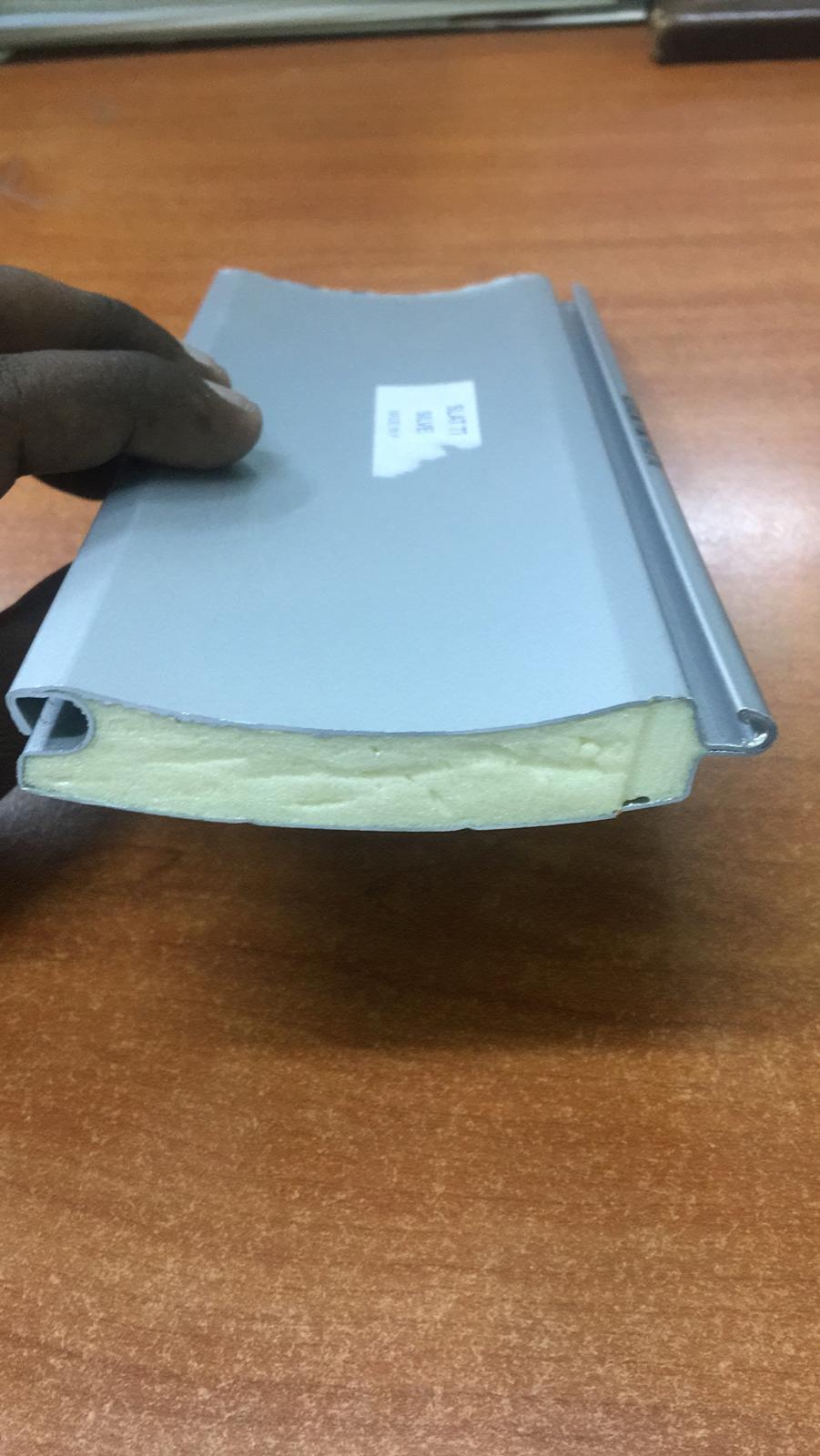

curving unistrut roll forming machine

Moreover, the use of a curving Unistrut roll forming machine enhances sustainability efforts — a crucial factor in today's environmentally conscious construction industry. Metal remains one of the most recyclable materials, and by minimizing waste during the strut formation process, this machine contributes positively to reducing the carbon footprint of construction projects. The precision with which it operates ensures that fewer errors translate into less material wastage, supporting sustainable building practices.

An industry expert noted that “the transformation brought about by the curving Unistrut roll forming machine is akin to moving from hand-crafting individual components to utilizing industrial precision on every scale.” Such authoritative endorsements reinforce the machine's status as a cornerstone in the toolkit of modern engineers and architects. It has redefined standards, setting a higher benchmark for fabrication quality and design innovation.

Trust in technology is built through consistent delivery and proven results — exactly what the curving Unistrut roll forming machine offers. Experience in the field has shown that companies investing in this technology see a growth in client trust as projects are completed with higher accuracy, speed, and a commitment to quality. The machine’s reliability reduces the likelihood of structural failures, improves the aesthetics of the finished infrastructure, and ultimately contributes to the safety and security of both the builders and end-users.

In conclusion, the curving Unistrut roll forming machine epitomizes excellence in structural engineering, standing at the intersection of tradition and innovation. By delivering efficiency, reliability, and adaptability, it serves as a testament to human ingenuity in enhancing building techniques for future generations. As technology continues to evolve, those in the industry who invest in sophisticated machinery like this are not just constructing buildings but are building towards a future that prioritizes quality, efficiency, and environmental stewardship.