Understanding C-Shape Purlin Roll Forming Machines

The construction industry relies heavily on various structural components that ensure the durability and stability of buildings. Among these components, C-shape purlins play a vital role. C-shape purlins are horizontal beams that provide support for roofs and walls in structures, primarily in steel buildings. With the increasing demand for such components, the process of fabricating these purlins has transformed significantly with the advent of C-shape purlin roll forming machines.

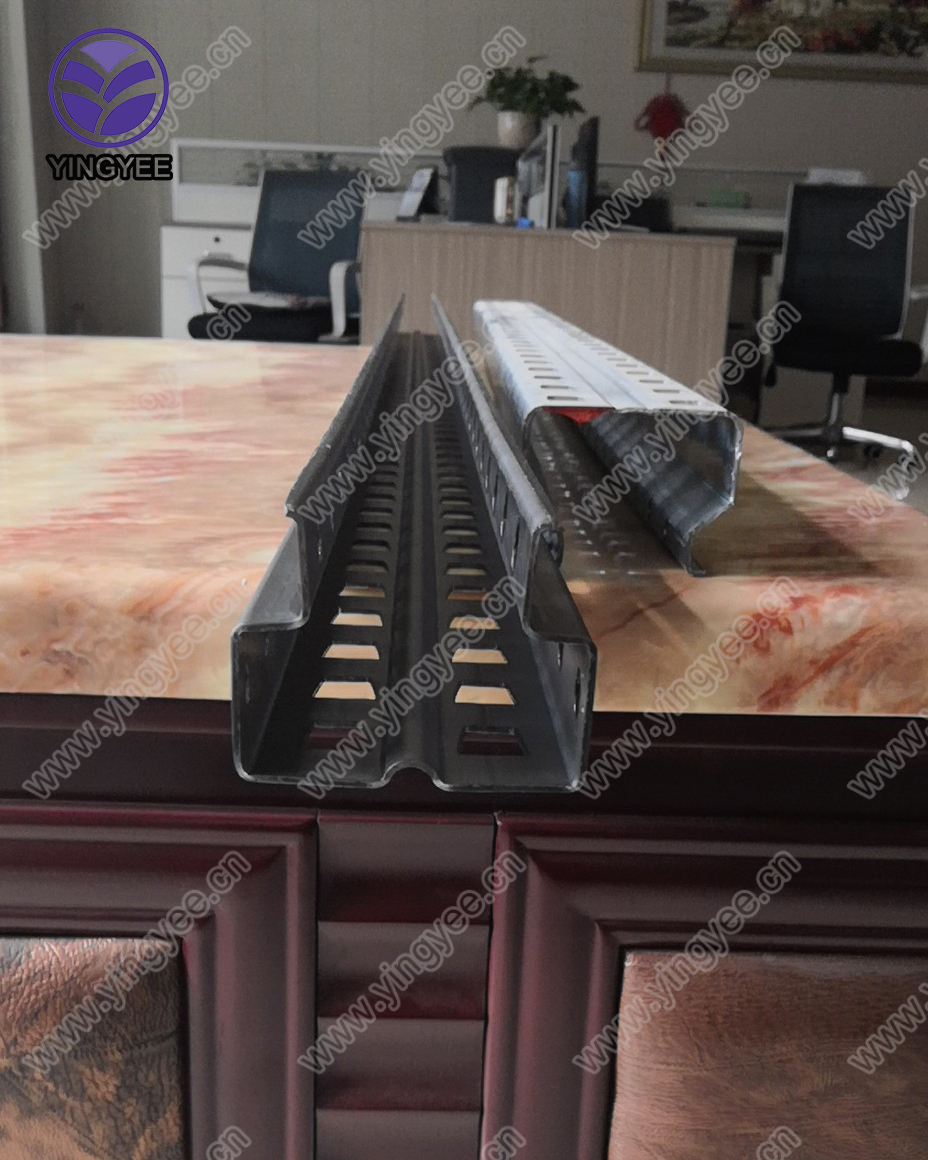

What is a C-Shape Purlin Roll Forming Machine?

A C-shape purlin roll forming machine is a specialized piece of equipment designed to produce C-shaped steel purlins through a continuous roll-forming process. This machine takes flat steel coils as raw material and processes them into C-shaped profiles with precision and efficiency. The roll forming process involves feeding the flat steel into a series of rollers, which gradually shape it into the desired C-profile. This approach not only enhances productivity but also ensures consistent quality in the produced purlins.

Components of C-Shape Purlin Roll Forming Machines

1. Decoiler The process begins with a decoiler that unwinds the steel coil. It ensures that the steel is fed into the machine smoothly and without interruptions.

2. Roll Forming System The heart of the machine. The roll forming system consists of multiple rollers that shape the steel into the C-profile. Each roller is precisely designed and positioned to ensure that the profile is formed accurately.

3. Cutting Mechanism After the steel has been formed into the desired shape, a cutting mechanism is employed to cut the formed purlin to the desired length. This can be either a manual or automated process, depending on the machine's specifications.

4. Control System Modern roll forming machines come equipped with advanced control systems that allow operators to set parameters such as speed, cutting length, and forming angles. This enhances user-friendliness and efficiency.

5. Output Table After cutting, the finished purlins are directed onto an output table for collection. This stage is crucial for organizing the finished pieces and facilitating further processing or immediate usage.

Advantages of C-Shape Purlin Roll Forming Machines

1. Efficiency One of the primary advantages of using a roll forming machine is the efficiency it brings to the manufacturing process. A single machine can produce a large quantity of purlins in a short period, making it ideal for high-demand projects.

2. Consistency and Precision Roll forming ensures that each purlin is made to the exact same specifications. This consistency is crucial in construction, as it helps maintain structural integrity.

3. Material Conservation The process utilizes material effectively, reducing waste. The machines can optimize the cut lengths to ensure minimal scrap is generated during production.

4. Versatility Many C-shape purlin roll forming machines can be adjusted to produce different sizes and specifications. This versatility allows manufacturers to cater to various construction requirements without needing multiple machines.

5. Automation and Technology Integration Modern machines can be integrated with automation technologies, allowing for remote monitoring and control. This not only improves operational efficiency but also enhances safety during the manufacturing process.

Conclusion

C-shape purlins are integral to the construction sector, providing structural support for various applications. The introduction of C-shape purlin roll forming machines has revolutionized the way these components are produced, resulting in increased efficiency, consistency, and reduced material waste. As technology continues to advance, we can expect further enhancements in these machines, making them even more effective in meeting the growing demands of the construction industry. For businesses looking to stay competitive, investing in high-quality roll forming machines is essential for ensuring they can meet the needs of their clients while maintaining quality and efficiency.