C-Shape Purlin Roll Forming Machine An Overview

In the realm of modern construction and manufacturing, efficiency and precision are paramount. One of the machines that exemplify these qualities is the C-shape purlin roll forming machine. This specialized equipment is designed to produce C-shaped purlins, which are crucial components in various structural applications, including the construction of warehouses, factories, and residential buildings. This article explores the working principles, applications, benefits, and technological advancements of C-shape purlin roll forming machines.

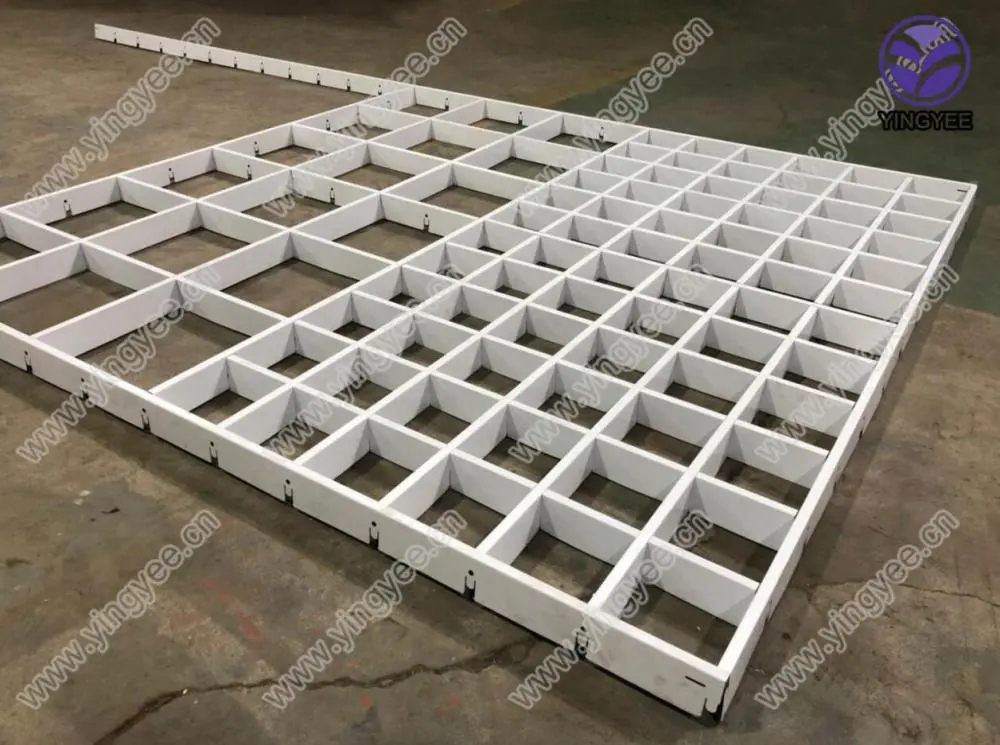

Understanding C-Shaped Purlins

C-shaped purlins are horizontal structural members used to support roofing and wall systems. Their distinctive shape, resembling the letter “C,” provides exceptional strength and stability while minimizing weight. Purlins are typically made from various materials, including steel and aluminum, and are critical in enhancing the structural integrity of buildings. They also facilitate easy installation of cladding systems, making them a preferred choice in the construction industry.

Working Principle of C-Shape Purlin Roll Forming Machines

A C-shape purlin roll forming machine operates on a straightforward yet sophisticated principle. The process begins with coiling a metal sheet, usually made of galvanized steel, which is then fed into the machine. The machine features a series of rollers that gradually shape the flat metal sheet into the desired C-profile.

Stages of the Forming Process

1. Feeding The flat metal sheet is fed into the machine, usually equipped with an automatic feeding system to enhance precision. 2. Forming The metal sheet passes through several sets of rollers that progressively bend and shape the material into the C-profile. The rollers are strategically designed to ensure uniformity and accuracy in the final product.

3. Cutting After the forming process is complete, the purlins are cut to the specified length. This can be done either manually or through an automated cutting system, enhancing efficiency and reducing labor costs.

4. Collection The finished C-shaped purlins are collected at the end of the machine for further processing or direct use in various construction projects.

Applications of C-Shaped Purlins

C-shaped purlins are widely utilized in numerous applications across the construction industry, including

- Roof Support They are primarily used to support roof structures in industrial buildings, agricultural facilities, and commercial establishments.

- Wall Support In addition to roofing, C-purlins provide essential support for wall cladding systems, enhancing overall building strength

.

- Framework Construction They are also employed in the construction of frameworks for modular buildings and temporary structures.

- Industrial Racking Systems C-purlins are often used in racking systems for warehouses, allowing for efficient storage solutions.

Advantages of C-Shape Purlin Roll Forming Machines

Investing in a C-shape purlin roll forming machine offers numerous advantages

- High Precision These machines generate accurate and consistent purlin profiles, which are essential for structural integrity.

- Cost-Effective By automating the production process, manufacturers can significantly reduce labor costs and material wastage, resulting in greater profitability.

- Flexibility Many modern roll forming machines are equipped with adjustable rollers, allowing manufacturers to produce various sizes and thicknesses of purlins as needed.

- Fast Production Rate Unlike traditional manufacturing methods, roll forming machines can produce purlins at high speeds, meeting the demands of large-scale construction projects.

- Durability The materials used in purlin production, combined with the precision of modern machines, result in high-quality, long-lasting structural components.

Technological Advancements

The C-shape purlin roll forming industry has seen significant technological advancements in recent years. Innovations such as computer numerical control (CNC) systems, automated setup, and integrated software for design and production have improved efficiency and accuracy. Additionally, advancements in material science have led to the development of stronger and lighter materials, further enhancing the performance of C-purlins.

Conclusion

The C-shape purlin roll forming machine is a vital asset in the construction and manufacturing sectors. Its ability to produce high-quality, durable, and precision-engineered C-shaped purlins serves a crucial role in modern building practices. As technology continues to evolve, these machines will become even more efficient and versatile, further revolutionizing the way we construct and design our environments. Whether for large-scale industrial projects or smaller construction endeavors, the C-shape purlin roll forming machine will undoubtedly remain a cornerstone of structural engineering.