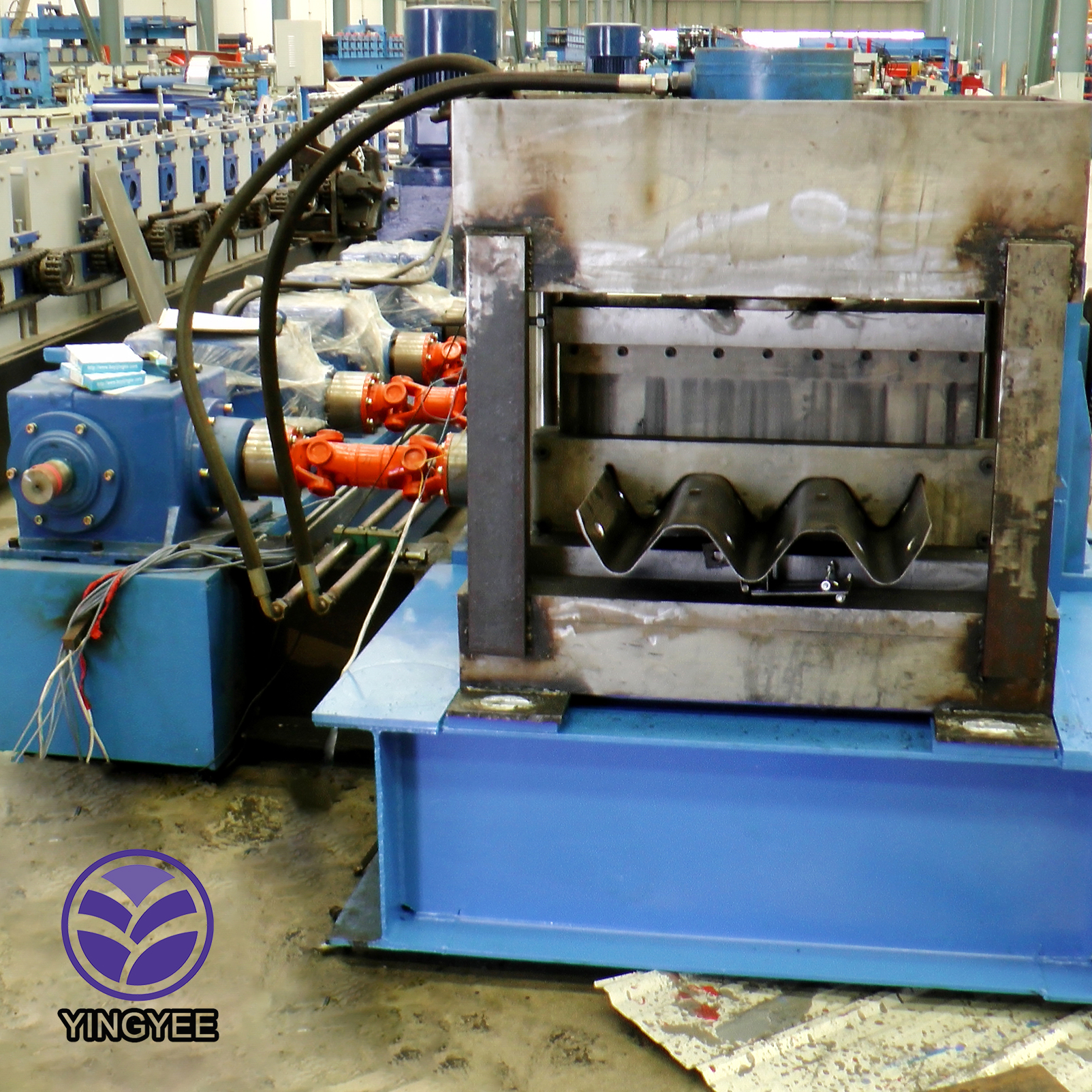

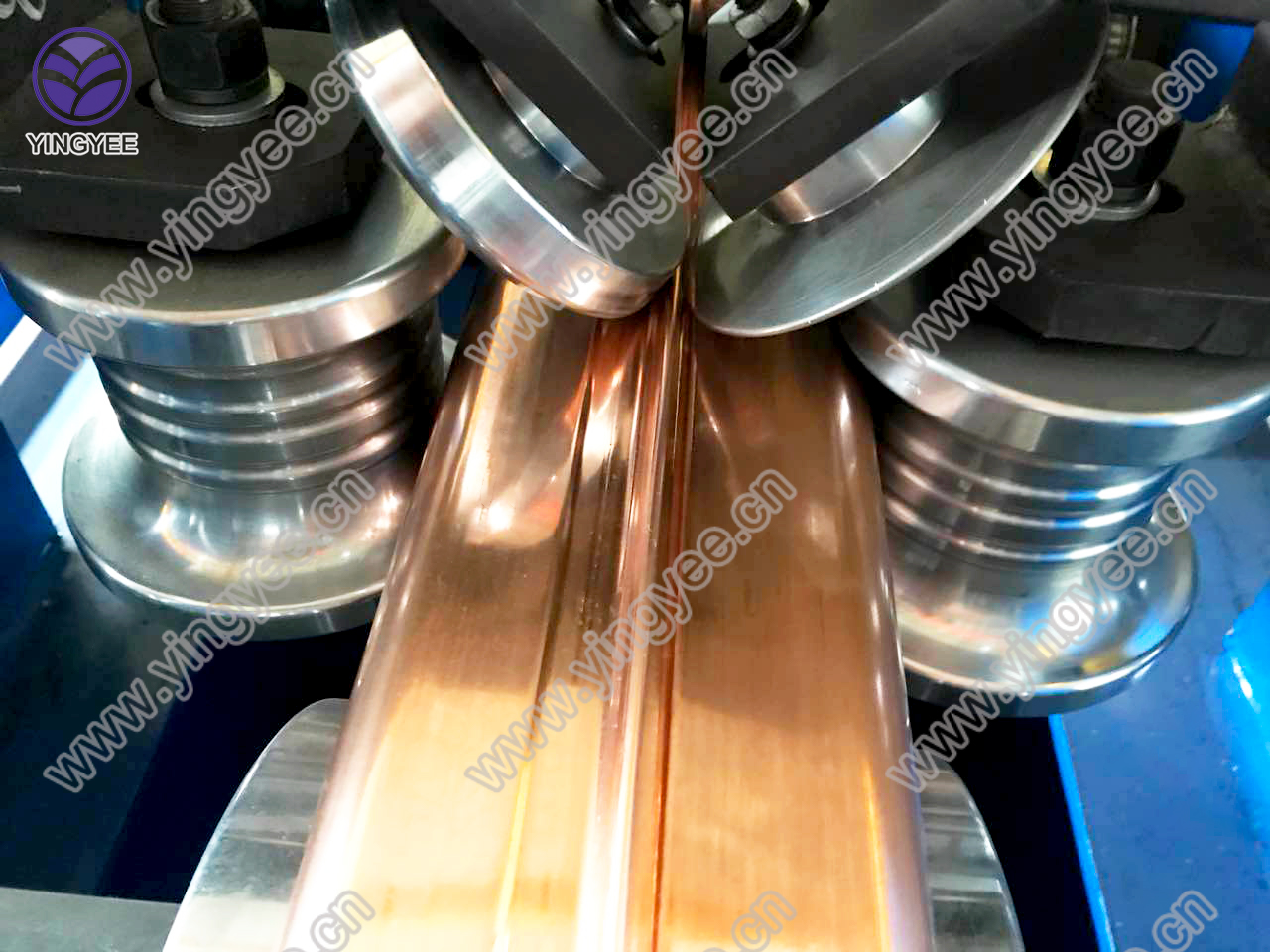

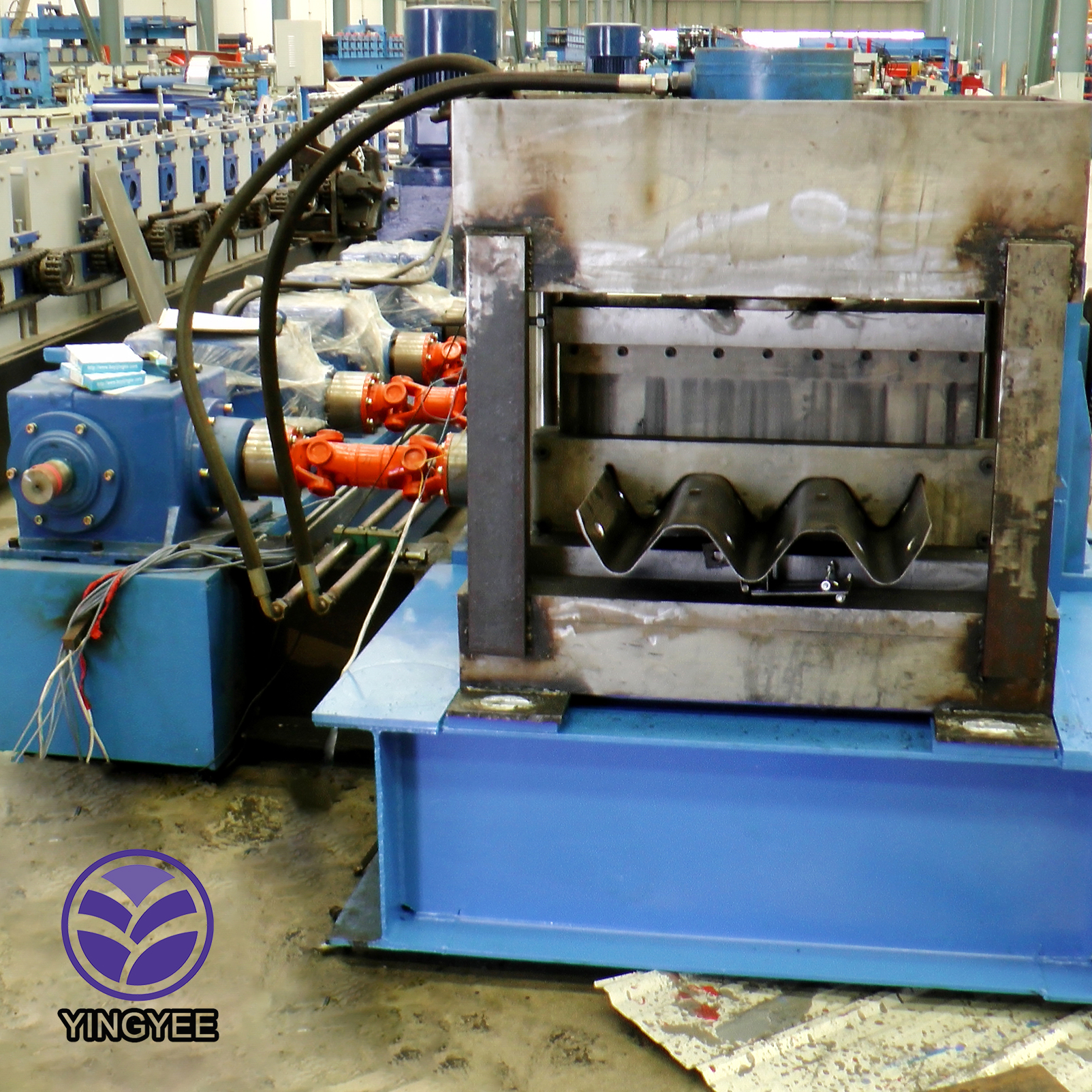

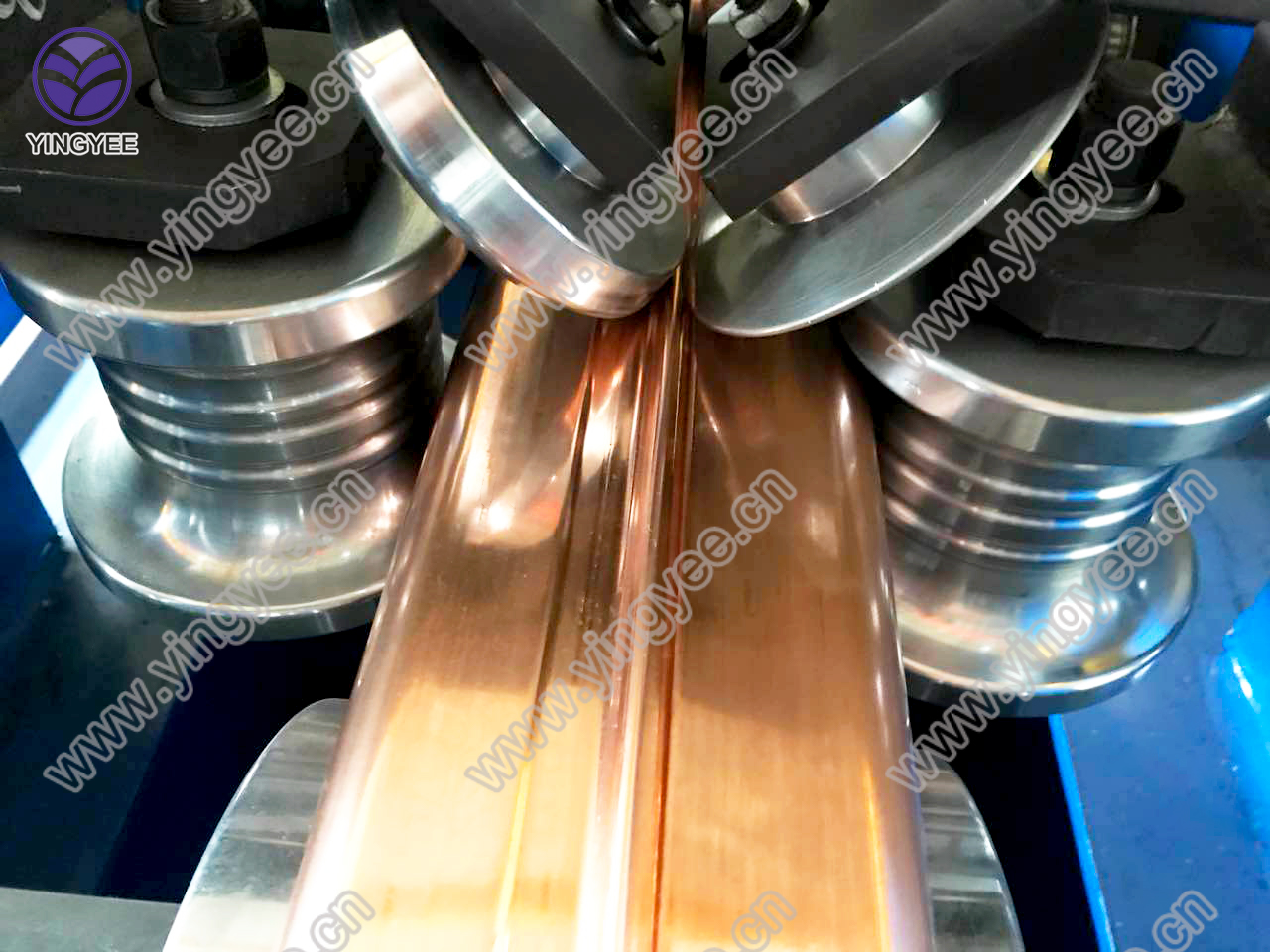

Navigating the intricacies of the crash barrier cold bending machine industry unveils the necessity for having machinery that combines precision with efficiency. This specialized equipment is essential for shaping metal barriers used across highways and other vital infrastructure. The complexity inherent in bending high-strength materials to precise angles without compromising their structural integrity calls for machines engineered to perfection.

Crash barrier cold bending machines are revolutionizing the world of highway safety by enabling manufacturers to produce barriers that conform to specific safety standards and geographic needs. The most advanced machines on the market are leveraging cutting-edge technology to deliver both speed and accuracy, ensuring that each bend serves its critical function in protecting lives on the road. One common misconception about these machines is that they are too complex for an average operator, but with advances in user-friendly interfaces and smart software integrations, even operators with moderate training can achieve excellent results.

Experience gained through extensive field testing has shown that the longevity and reliability of these machines are paramount. Manufacturers invest substantial resources in the R&D phase to ensure the machines perform under all conditions, whether it's extreme cold or intense workloads. The materials used in these machines are chosen for durability, ensuring they can withstand the rigor of continuous use without frequent breakdowns. Operators and managers in fabrication plants consistently report the importance of investing in quality machinery to minimize downtime and maintain production schedules.

From an expertise standpoint, selecting the right crash barrier cold bending machine requires a discerning eye for specifications tailored to meet specific project requirements. Engineers and procurement managers should look for machines that offer variable bending radius capabilities and automated adjustment features. These attributes ensure that the machine can accommodate various median and shoulder barriers, from standard to highly specialized designs. Moreover, machines with integrated diagnostics and remote monitoring capabilities are setting new standards for operational efficiency by providing real-time data to operators and enabling quick responses to any potential issues.

crash barrier cold bending machine

Authoritativeness in the domain of crash barrier production often correlates with manufacturers' commitment to adhering to internationally recognized standards such as ISO certifications. These frameworks ensure that all processes, from design to production, meet predefined quality and safety benchmarks. Engaging with a manufacturer that demonstrates such commitment automatically elevates the trustworthiness of their machines. Furthermore, they often offer comprehensive training programs, both in-person and virtual, to ensure that operators are well-versed in best practices for machine operation and maintenance.

Trustworthiness is further bolstered through partnerships with industry leaders and governments. Machines that have been certified by third-party organizations or tested under stringent government safety protocols bring an added layer of assurance. This credibility, combined with a robust warranty policy, makes these machines a reliable choice for companies aiming to enhance their infrastructure development portfolios.

Finally, feedback from current users serves as an invaluable resource. Operators of recent models of crash barrier cold bending machines have praised innovations such as enhanced energy efficiency and reduced carbon footprints. These elements are critical in modern manufacturing environments where sustainability is as crucial as profitability. The move towards greener machinery aligns with global goals for reducing industrial emissions and promotes a positive brand image to stakeholders and the public.

In conclusion, the investment in a crash barrier cold bending machine extends beyond its immediate functionality. It is about choosing a reliable partner in manufacturing efficiency, safety adherence, and sustainability goals. By opting for state-of-the-art technology and aligning with reputable manufacturers, companies can ensure that they are not only producing top-notch road safety solutions but also positioning themselves as leaders in the ever-evolving world of industrial fabrication. As this technology continues to evolve, businesses that leverage its full potential will undoubtedly lead the charge in shaping a safer travel future worldwide.