In the realm of industrial construction and utility frameworks, the strut channel machine stands out as a pivotal innovation, bridging efficiency with precision. As industries evolve with demands for scalable and adaptable solutions, the role of a strut channel machine has become more pronounced, driving the momentum towards streamlined construction processes.

The strut channel machine operates as an intricate tool, catering to the production of strut channels which are vital in mounting, bracing, supporting, and connecting lightweight structural loads. These channels are ubiquitous in utilizations ranging from wiring, plumbing, mechanical systems, to massive infrastructure projects. Their flexibility in design, combined with the durability, positions them as a preferred choice for engineers and architects alike.

One of the hallmark features of a proficient strut channel machine is its capacity for customization. Modern models of these machines come equipped with automated settings that allow users to tailor channels to specific sizes, gauges, and configurations. This adaptability not only optimizes the use of raw materials but also accommodates site-specific requirements, enhancing overall project efficiency. It is this level of customization that highlights the machine's expertise in meeting diverse construction demands.

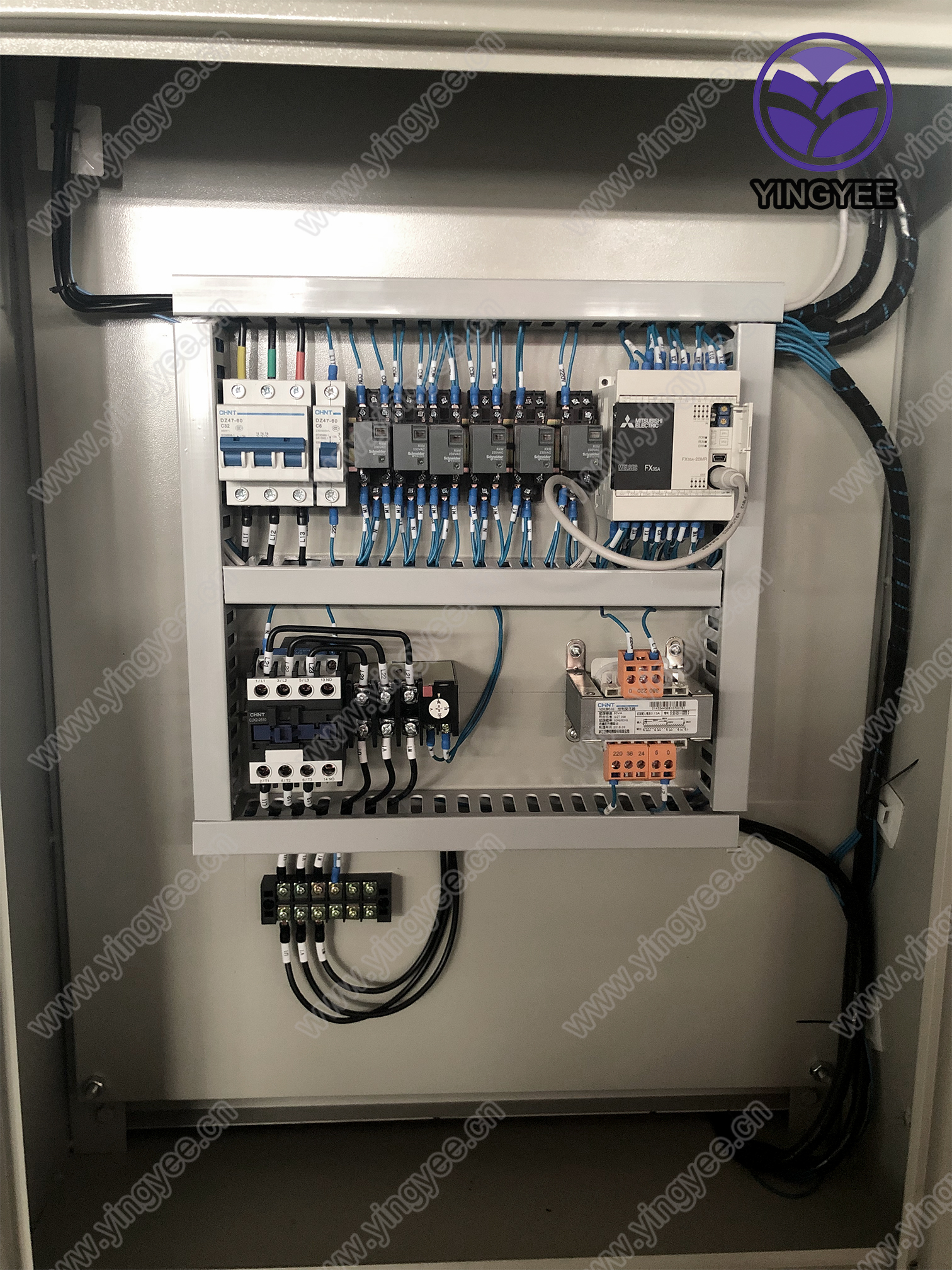

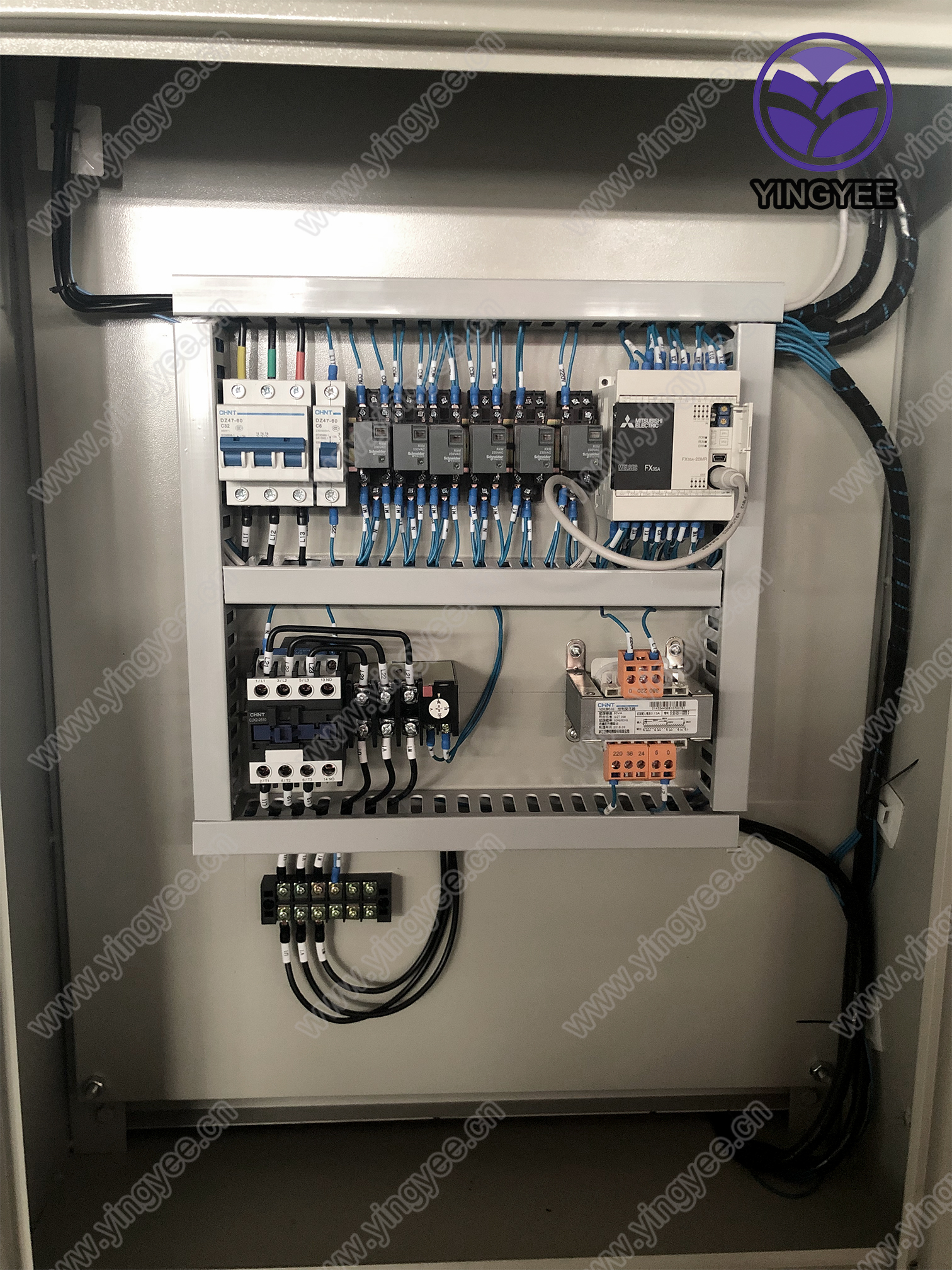

Delving deeper, the expertise inherent in operating a strut channel machine is crucial for maximizing its potential. Trained operators can leverage the full suite of functionalities—whether it's adjusting the forming rollers, calibrating the hydraulic punch, or managing the cutting length with acute precision. The involvement of technical craftsmanship ensures that every channel produced aligns with stringent industry standards, establishing the credibility of outputs as viable components in large-scale projects.

strut channel machine

Moreover, the authority of these machines in the industrial niche is underscored by advancements in smart technology. Integration of IoT capabilities allows for real-time monitoring of production metrics, predictive maintenance, and seamless alignment with digital project blueprints. Such innovations not only boost operational efficiency but also enforce a quality control mechanism that fortifies the reliability of the entire production process.

From a trustworthiness perspective, investing in a strut channel machine concocts a symphony of cost-effectiveness and longevity. Businesses can cut down outsourcing expenses by empowering in-house capabilities. The consistency in the production quality mitigates risks associated with material failure—an assurance that reverberates trust in each project timeline and stakeholder expectation.

Case studies amplify the narrative of these machines' pivotal role. Consider the refurbishment of urban infrastructure; a project dependent on precise timelines and deft deployment of resources. Strut channel machines enable rapid, onsite fabrication of components, negating potential delays and expediting project completion. These practical experiences serve as a testimony to their indispensable utility and the expert craftsmanship they embody.

In conclusion, the strut channel machine is not merely a tool but an embodiment of innovation driving forward the industrial and construction sector. Its ability to deliver customized, quality-ensured solutions with technological adeptness, positions it as an essential asset in contemporary project execution. Harnessing its full capacity ensures that businesses not only meet but exceed their operational benchmarks, sustaining their competitive edge in a dynamic market landscape.