Crash barrier cold bending machines are revolutionizing the way we ensure safety on roads. These innovative machines are designed specifically to bend steel crash barriers at various angles without the need for heating, providing efficient solutions that meet global safety standards. Drawing from years of experience and expertise, this article delves into the intricacies, expert applications, and authoritative advantages of this essential piece of equipment, while building trust with manufacturers and end-users.

Cold bending, as opposed to traditional hot bending methods, involves reshaping a metal at room temperature. This method ensures the integrity and strength of the metal remain uncompromised, a vital factor in crash barriers where structural rigidity can be a matter of life and death. The adoption of the cold bending process in modern engineering has proven to increase the longevity and reliability of crash barriers used in highways across the globe.

Manufacturers of crash barrier cold bending machines, with decades of experience, emphasize precision engineering. These machines blend sophisticated design with cutting-edge technology to ensure uniform bends. The ability to consistently produce accurate bends not only guarantees compliance with international safety standards but also minimizes waste, turning it into a financially sound investment for infrastructure projects.

Expertise in the field of metal bending machinery is crucial. Engineers and architects rely on the precision of cold bending machines when designing crash barriers for roads with intricate designs. These machines have proven indispensable in crafting bespoke barriers that seamlessly fit within complex geographical locations, such as winding mountain roads or urban environments with space constraints. With computer-aided designs, every angle and curve is pre-determined, ensuring seamless implementation on site.

Authoritativeness in the domain of crash barrier manufacturing is often determined by adherence to stringent quality control measures. Leading manufacturers conduct multiple stages of testing, ensuring that each bend produced by the machine can withstand extreme environmental conditions and substantial physical impact. Certification from recognized international safety boards further reinforces the machine's reliability, granting peace of mind to contractors and government agencies alike.

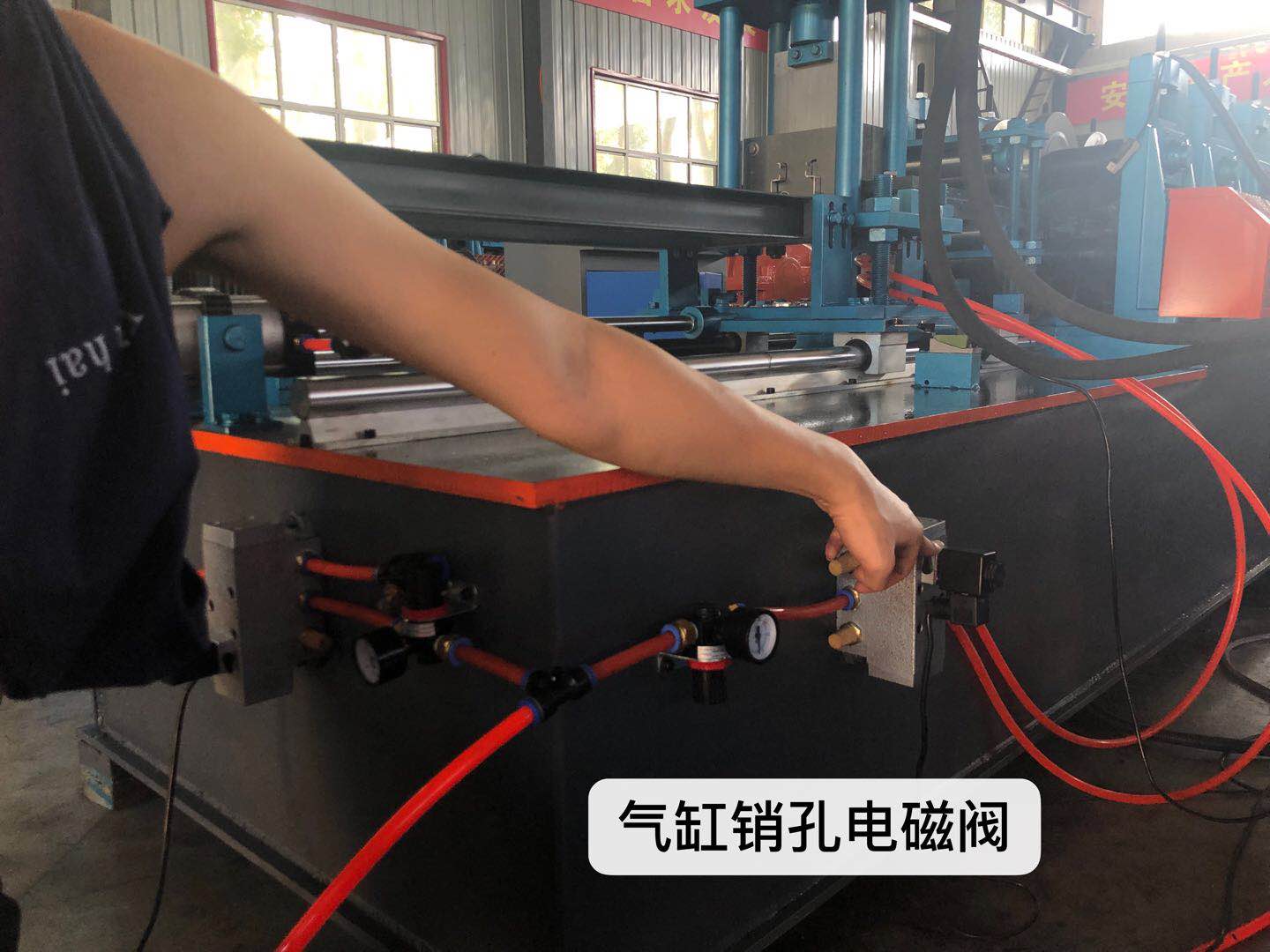

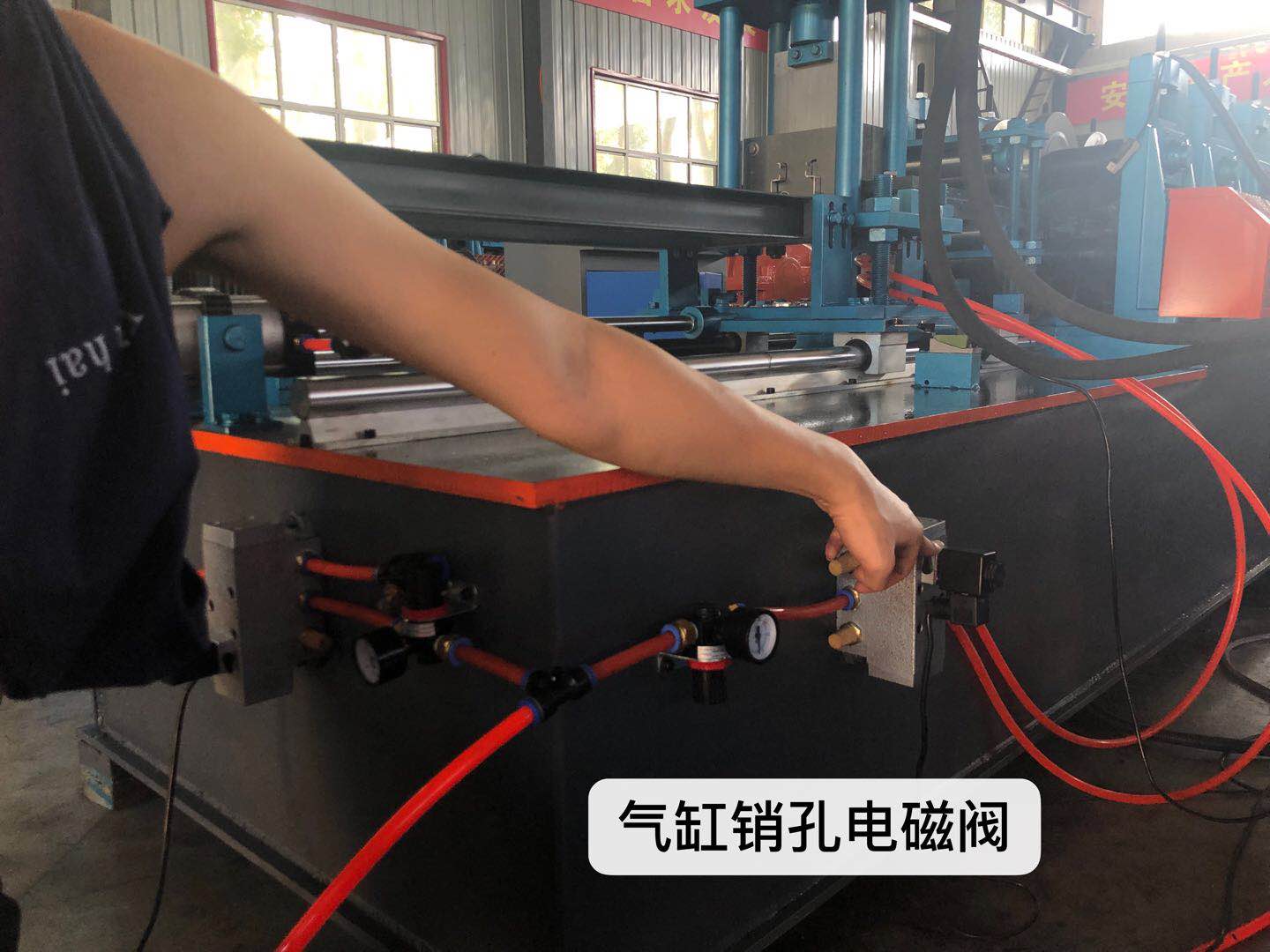

crash barrier cold bending machine

The trustworthiness of crash barrier cold bending machines extends to their operational efficiency. Equipped with user-friendly interfaces, these machines allow operators to perform complex procedures without extensive prior training. Robust construction and low-maintenance designs ensure high uptime, catering to projects with tight deadlines without compromising on quality or safety.

In addition to the technical benefits, investing in crash barrier cold bending machines reflects a commitment to sustainability. Energy consumption is significantly reduced when compared to hot bending alternatives, contributing to lower operational costs and a reduced carbon footprint. This aspect is gaining increasing attention from environmentally conscious stakeholders who demand ecologically responsible solutions in public infrastructure.

Future advancements in technology promise to enhance the capabilities of these machines even further. Integration with Internet of Things (IoT) devices and real-time data analytics is on the horizon, facilitating predictive maintenance and advanced quality control. The continual evolution of materials technology will likewise offer enhanced metal compositions that increase the resilience and durability of crash barriers, optimizing the use of cold bending techniques.

In conclusion, the crash barrier cold bending machine is a cornerstone of modern road safety, combining engineering precision with environmentally sustainable practices. This machinery stands as a testament to human ingenuity in striving for safety without sacrificing efficiency. As road networks expand and urban planning becomes increasingly complex, the demand for these machines is set to grow, reaffirming the significance of expert design, authoritative testing, and the consistent delivery of trustworthy solutions.