Cold Bending Machines for Crash Barriers An Essential Tool in Road Safety

As the reliance on vehicles increases, ensuring road safety has never been more paramount. One of the critical components in enhancing road safety is the implementation of crash barriers. These robust structures are designed to absorb the impact of vehicles and prevent them from veering off the road or into opposing traffic. An essential tool in the production of these barriers is the cold bending machine, a technology that revolutionizes the manufacturing process.

Cold Bending Machines for Crash Barriers An Essential Tool in Road Safety

The benefits of using cold bending machines in the manufacture of crash barriers are numerous. Firstly, cold bending offers improved precision. The machines are equipped with advanced technology and computer numerical control (CNC) systems, which allow for exact specifications to be met with minimal deviation. This precision is vital when creating crash barriers that must fit seamlessly into various road conditions and configurations.

Moreover, cold bending reduces the risk of material failure. Unlike hot bending, which can alter the metallurgical properties of the steel, cold bending preserves the material's strength and durability. This aspect is particularly important for crash barriers, as any weaknesses can compromise their effectiveness in real-world crash scenarios. By using a cold bending machine, manufacturers can ensure that their products meet the stringent safety standards required for roadway installations.

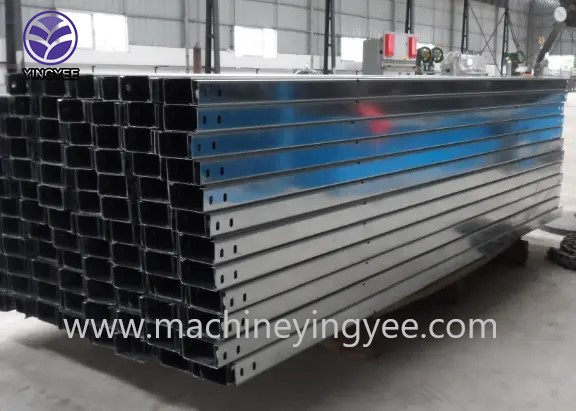

Additionally, the efficiency offered by cold bending machines cannot be overstated. These machines can process large quantities of steel quickly, significantly reducing manufacturing lead times. In an era where rapid production is often the key to business success, being able to produce high volumes of crash barriers without sacrificing quality is a considerable advantage. The integration of automation in many contemporary cold bending machines further enhances this efficiency, allowing for continuous production cycles with minimal manual intervention.

Safety regulations and standards in the transportation sector continue to evolve, pushing manufacturers to innovate continuously. The introduction of advanced cold bending machines is a response to these demands, enabling businesses to keep pace with regulatory requirements while enhancing the safety of road users. By adopting modern manufacturing technologies, companies can produce crash barriers that not only comply with current safety norms but also anticipate future standards.

In conclusion, cold bending machines play a pivotal role in the production of crash barriers, an essential element of road safety. Their ability to provide precise, durable, and efficient manufacturing processes addresses the pressing needs of road safety manufacturers. As the transportation landscape continues to evolve, the importance of integrating advanced machinery like cold bending machines will only grow. By investing in technologies that enhance the effectiveness of crash barriers, we take critical steps towards creating safer roads for everyone. The future of road safety is undoubtedly linked to the innovations in manufacturing processes, ensuring that our infrastructures can effectively protect lives on the road.