The Role of Crash Barrier Roll Forming Machines in Road Safety

In recent years, road safety has become a paramount concern for governments and transportation authorities worldwide. One of the significant advancements in this field is the use of crash barrier roll forming machines, which have revolutionized the way we produce safety barriers. These machines play a crucial role in ensuring that highways, roads, and vehicle paths are adequately protected against potential accidents, thereby saving lives and preventing injuries.

Crash barriers, commonly found along highways and at road construction sites, are designed to absorb the impact of vehicles and redirect them in a controlled manner. The materials used for these barriers must meet specific safety and durability standards. This is where crash barrier roll forming machines come into play. They are designed to efficiently produce high-quality steel sections that are both sturdy and capable of withstanding severe impacts.

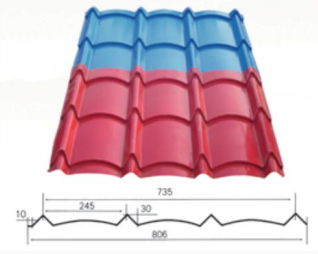

The roll forming process is highly efficient, enabling manufacturers to create complex shapes and profiles from metal sheets. These machines work by passing a continuous strip of metal through a series of rollers, which gradually shape the metal into the desired profile. The result is a strong, uniform product that can be deployed as crash barriers on roads. This automated process not only speeds up production but also minimizes waste, making it an environmentally friendly option.

One of the significant advantages of using crash barrier roll forming machines is the flexibility they offer in design. Manufacturers can customize the shape and size of the barriers to meet specific requirements based on location and intended use. For instance, some areas may require more robust barriers due to higher traffic speeds or increased accident rates, while other locations may need lighter, more straightforward designs. This adaptability ensures that road safety measures can be tailored to suit different environments.

Moreover, the use of advanced materials, such as galvanized steel, enhances the durability and longevity of crash barriers produced by these machines. Galvanization provides a protective coating that prevents rust and corrosion, significantly extending the lifespan of the barriers. As a result, highways and roads equipped with these barriers require less maintenance, which is crucial for keeping operational costs down for transportation authorities.

In addition to their practical benefits, crash barrier roll forming machines also contribute to job creation and economic development. As demand for road safety measures continues to rise, so does the need for skilled workers who can operate and maintain these machines. This creates opportunities within the manufacturing sector, leading to job growth and supporting local economies.

In conclusion, crash barrier roll forming machines are an integral component of modern road safety infrastructure. Their ability to produce high-quality, customizable barriers quickly and efficiently contributes to a safer driving environment. By continually improving these machines and the processes associated with them, we can enhance road safety measures, minimize accidents, and ultimately save lives. As the world becomes more interconnected through transportation, the importance of reliable crash barriers cannot be overstated. These machines represent a significant step forward in our commitment to protecting motorists and pedestrians alike.