The Importance of C Purlin Roll Forming Machines in Modern Construction

C purlin roll forming machines have become an essential part of the construction industry, particularly in the production of C purlins, which are widely used in steel structures. These machines streamline the manufacturing process, making it faster and more efficient while ensuring high-quality outputs. In this article, we will delve into the details of C purlin roll forming machines, their benefits, and their impact on contemporary construction practices.

Understanding C Purlins

Before exploring the machinery involved, it’s essential to understand what C purlins are. C purlins are horizontal beams that are typically used in the construction of roofs and wall systems. They provide essential support and are often utilized in both commercial and residential buildings. Their shape resembles the letter C, which contributes to their strength and efficiency in load-bearing applications.

The Role of Roll Forming Machines

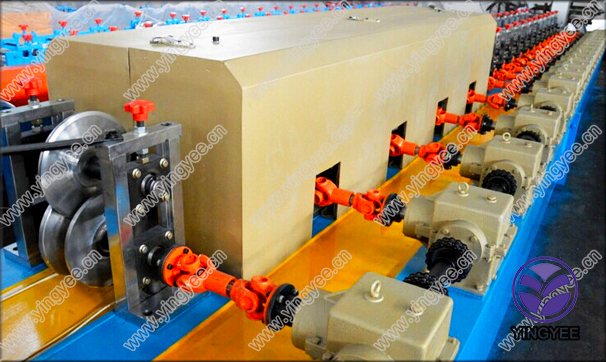

C purlin roll forming machines are designed to convert flat steel sheets into intricate C-shaped profiles through a continuous bending process. The manufacturing process begins with feeding metal coils into the machine, which then shapes these coils into the desired purlin profile. This production method is favored for its ability to produce long lengths of purlins with minimal waste.

Advantages of Using C Purlin Roll Forming Machines

1. Efficiency One of the most significant advantages of using C purlin roll forming machines is their efficiency. These machines operate at high speeds, enabling manufacturers to produce large quantities of C purlins in a relatively short period. Automation features in modern machines further enhance productivity by minimizing manual intervention.

2. Precision Roll forming machines ensure precision in manufacturing. With advanced technology, they can maintain uniform dimensions and consistent quality across all purlin products. This precision is critical for structural integrity, as even minor discrepancies can lead to severe consequences in construction.

3. Cost-Effectiveness Although the initial investment in a C purlin roll forming machine can be significant, the long-term savings are substantial. The reduction of labor costs, combined with the minimization of material waste, leads to a higher return on investment. Additionally, the ability to produce just-in-time inventory can further lower overall project costs.

4. Versatility These machines are highly versatile and can be adjusted to produce different sizes and specifications of C purlins. This flexibility allows manufacturers to meet diverse client needs and adapt to changing market demands quickly.

5. Quality Control Many C purlin roll forming machines come equipped with advanced control systems that monitor the manufacturing process. This feature ensures that any deviations from set standards are detected early, allowing for immediate corrective actions to maintain product quality.

Impact on Modern Construction

The advent of C purlin roll forming machines has revolutionized the construction industry. Their ability to produce strong, consistent, and lightweight purlins has led to more robust structural designs and innovations. Furthermore, the speed and efficiency of these machines can significantly reduce project timelines, enabling construction firms to complete projects quicker and meet client deadlines.

Additionally, as sustainability becomes increasingly important in construction, the roll forming process contributes to reducing waste. This environmentally friendly approach aligns with global efforts to promote sustainability in building practices, making C purlin roll forming machines a preferred choice in modern construction.

Conclusion

C purlin roll forming machines have transformed the way steel structures are manufactured. By providing efficiency, precision, cost-effectiveness, versatility, and quality control, these machines play a crucial role in the construction industry today. As the demand for sustainable and innovative building solutions grows, the significance of C purlins and the machines that produce them will only continue to rise. Embracing this technology is key to staying competitive in an ever-evolving marketplace, making C purlin roll forming machines a vital investment for forward-thinking manufacturers.