C Purlin Roll Forming Machine A Comprehensive Overview

In the modern construction industry, the demand for quality materials is ever-increasing, particularly when it comes to steel structures. One essential component that has gained significant popularity is the C purlin, a type of structural steel that provides support for roofs and walls. To meet this demand, manufacturers have turned to advanced technologies, particularly the C purlin roll forming machine. This article delves into the essence of C purlin roll forming machines, their applications, benefits, and the factors to consider when choosing a factory for purchasing.

Understanding C Purlins

C purlins are versatile steel sections that resemble the letter C in cross-section. They are primarily used in the construction of buildings, warehouses, and other structures where there is a need for reliable support. C purlins can be utilized for various purposes, including providing a framework for roofs, aiding in the construction of walls, and supporting other structural load components. Their lightweight design, combined with their strength and durability, makes them an ideal choice for many construction projects.

C Purlin Roll Forming Machine The Backbone of Production

A C purlin roll forming machine is specialized equipment designed to create C-shaped purlins from steel coils. The roll forming process begins with feeding a flat steel strip through a series of rollers, which gradually shape the material into the desired C profile. This method of production is known for its efficiency, precision, and ability to produce large quantities of purlins quickly.

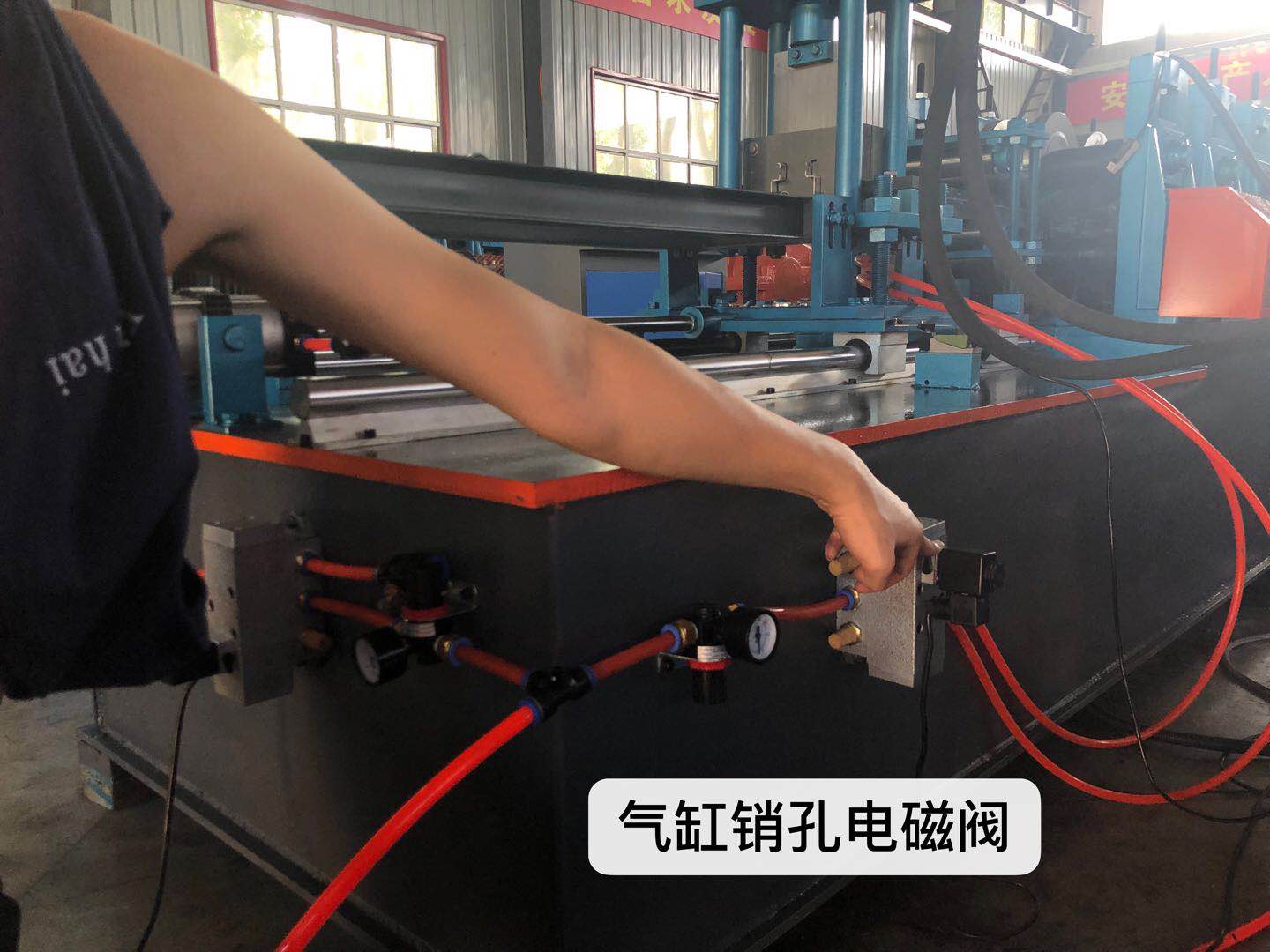

The key components of a C purlin roll forming machine include

1. Decoiler Unwinding the steel coil and feeding it into the forming process. 2. Roll Forming Stations Multiple sets of rollers that gradually shape the steel strip into the final C profile. 3. Cutting Unit After forming, the purlins are cut to the specified length. 4. Control System Modern machines are equipped with advanced control systems that allow for precise adjustments and automation of the forming process.

Benefits of Using C Purlin Roll Forming Machines

1. High Production Efficiency These machines can produce C purlins at a rapid pace, significantly increasing output compared to manual methods. 2. Cost-Effectiveness By optimizing the use of raw materials and minimizing waste, businesses can achieve substantial cost savings over time. 3. Customization Many roll forming machines allow for customization in terms of sizes and thicknesses, catering to diverse project requirements. 4. Quality Assurance The automation and precision involved in the roll forming process ensure consistently high-quality products that meet industry standards.

Choosing the Right Factory for Your C Purlin Roll Forming Machine

When considering the acquisition of a C purlin roll forming machine, selecting the right factory is crucial. Here are key factors to keep in mind

1. Experience and Reputation Look for manufacturers that have a solid track record in the industry. Established factories are more likely to produce reliable and durable machines.

2. Customization Options Choose a factory that offers customization according to your specific needs, including the ability to adjust machine parameters for different purlin specifications.

3. Technical Support and Service A reputable manufacturer will provide comprehensive after-sales support, including installation, maintenance, and repair services.

4. Quality of Materials Ensure the factory uses high-quality materials in the construction of its machines to enhance durability and performance.

5. Pricing While cost is a factor, it should not be the only determining element. Compare offerings from different manufacturers to find the best combination of quality and price.

In conclusion, C purlin roll forming machines play a crucial role in the construction industry by streamlining the production of essential structural components. By investing in high-quality machinery from a reputable manufacturer, construction businesses can enhance their operational efficiency, reduce costs, and ensure the delivery of superior products to their clients.