C Purlin Roll Forming Machine A Comprehensive Overview

C purlins are essential components in modern structural engineering, providing a strong and efficient solution for various building applications. As demand for these robust profiles increases, the necessity for efficient manufacturing processes has led to the development of specialized machinery, notably the C purlin roll forming machine. This article aims to provide an overview of the functionality, benefits, and features of these machines, particularly from the perspective of factory production.

What is a C Purlin Roll Forming Machine?

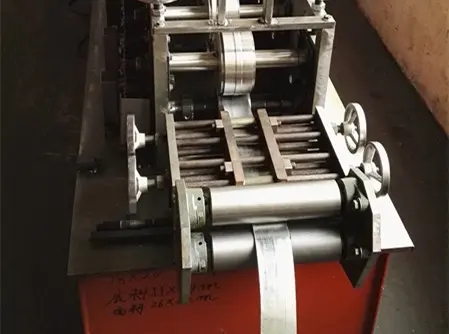

A C purlin roll forming machine is a device designed to transform steel coils into C-shaped purlins, which are used predominantly in the construction of warehouses, buildings, and other structures. The machine operates by feeding a steel coil through a series of rollers that progressively shape the material into the desired C profile. The process often includes cutting the formed purlin to specific lengths, making the operation efficient and continuous.

Benefits of C Purlin Roll Forming Machines

1. Efficiency in Production These machines significantly enhance production speed compared to traditional cutting methods. Once set up, they can produce a continuous stream of purlins with minimal labor input.

2. Material Conservation Roll forming is an efficient use of raw materials. Since the process shapes the material without generating significant waste, manufacturers can enjoy cost savings on metal usage.

3. Precision Engineering Advanced C purlin roll forming machines come equipped with computerized systems that allow for precise control over dimensions and tolerances. This precision is crucial for structural integrity in construction projects.

4. Versatility Modern machines can be easily adjusted to produce various sizes and thicknesses of purlins, making them suitable for different construction needs. This adaptability allows manufacturers to cater to a diverse clientele.

5. Durability and Strength The formed C purlins exhibit high strength-to-weight ratios, essential for structural applications. They are capable of bearing heavy loads, making them a popular choice in the construction sector.

Choosing the Right Machine

When selecting a C purlin roll forming machine for a factory, several factors should be considered. These include the machine's production capacity, operational speed, energy consumption, and ease of maintenance. Additionally, manufacturers should evaluate the after-sales support and training provided by the machine suppliers to ensure smooth operation.

Conclusion

In conclusion, the C purlin roll forming machine is a vital asset in modern manufacturing, offering efficiency, precision, and versatility in producing high-quality C-shaped purlins. As construction demands continue to evolve, the integration of such machinery is crucial for companies aiming to maintain a competitive edge while meeting the structural needs of the market. Investing in advanced roll forming technology not only enhances production capabilities but also contributes to the overall quality and reliability of construction materials.