Understanding C Purlin Roll Forming Machines

C purlin roll forming machines are essential tools in modern construction and manufacturing. These machines are designed to efficiently produce C purlins, which are critical structural components in various construction applications. The versatility and efficiency of C purlins make them a preferred choice for builders and engineers alike.

What is a C Purlin?

A C purlin is a C-shaped steel channel, typically used in building frames for support and load-bearing applications. They are often utilized in the construction of warehouses, factories, and commercial buildings, due to their lightweight yet strong characteristics. The design of C purlins allows for easy integration with other structural components, making them essential in creating robust structural frameworks.

How Does a C Purlin Roll Forming Machine Work?

C purlin roll forming machines operate through a continuous production process that involves several key stages. Initially, steel coils are fed into the machine. These coils are made of high-strength steel, ensuring that the final purlins can withstand significant loads.

1. Material Preparation The machine begins with the uncoiling of the steel coil. The uncoiling process aligns the material and prepares it for reshaping.

2. Roll Forming The core of the machine is a series of rollers that gradually shape the steel into the desired C profile. Through a series of forming stations, the steel is bent and shaped into a C purlin. This process allows for precise control over the dimensions of the purlins, ensuring uniformity and accuracy.

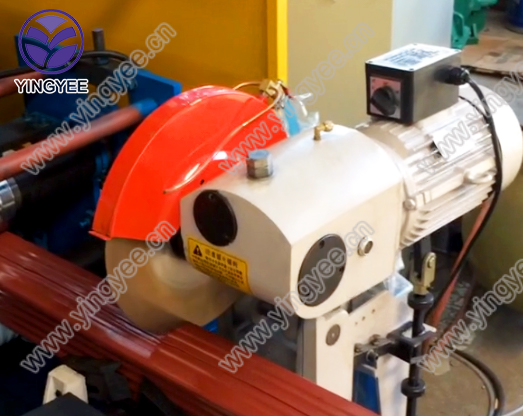

3. Cutting Once the desired length is achieved, the purlin is cut to size using a cutting tool. This can be done through varying methods, including shear cutting, producing clean and accurate cuts.

4. Finishing After cutting, the purlins can go through finishing processes such as galvanizing, painting, or coating, which enhances their durability and resistance to corrosion.

Advantages of Using C Purlin Roll Forming Machines

1. Efficiency One of the most significant benefits of using a C purlin roll forming machine is the efficiency of the production process. High-speed machines can produce large quantities of purlins in a short amount of time, meeting the demands of fast-paced construction projects.

2. Cost-Effective With the ability to create purlins at scale, manufacturers can reduce labor costs and raw material waste. The automation of the roll forming process also minimizes production errors.

3. Customization Modern roll forming machines allow for customization. Operators can adjust the dimensions and specifications of the purlins being produced, catering to specific project needs without requiring a complete overhaul of the machinery.

4. Quality Control The precise nature of roll forming means that the quality of the finished purlins is consistently high. The machines are designed to maintain strict tolerances, ensuring that each product meets relevant structural standards.

Applications of C Purlins

C purlins are widely used in several applications due to their strength and flexibility in design. Common uses include

- Construction Frames Used in both residential and commercial buildings as structural supports. - Roofing Systems Serve as crucial components in roof structures, providing support for roofing sheets. - Bracing Systems Employed in various bracing applications, enhancing the stability of structures. - Industrial Applications Found in factory facilities and warehouses where robust framing is crucial for large spans.

Conclusion

C purlin roll forming machines are a vital innovation in the field of construction and manufacturing. Their ability to produce high-quality, durable purlins at a rapid pace has revolutionized the way builders approach their projects. By streamlining the production process and ensuring material efficiency, these machines not only improve productivity but also contribute to the construction of safer and more reliable structures. As technology advances, we can expect even greater enhancements in the capabilities of C purlin roll forming machines, further solidifying their essential role in the industry.