Corrugated Steel Panel Roll Forming Machine Revolutionizing Modern Building Solutions

In today’s fast-paced construction industry, the demand for durable yet lightweight building materials continues to rise. Among the various options available, corrugated steel panels have gained immense popularity due to their superior strength, lightweight nature, and aesthetic appeal. The machinery responsible for producing these panels is known as the corrugated steel panel roll forming machine. This machine plays a pivotal role in modern construction, providing a solution that combines efficiency, quality, and cost-effectiveness.

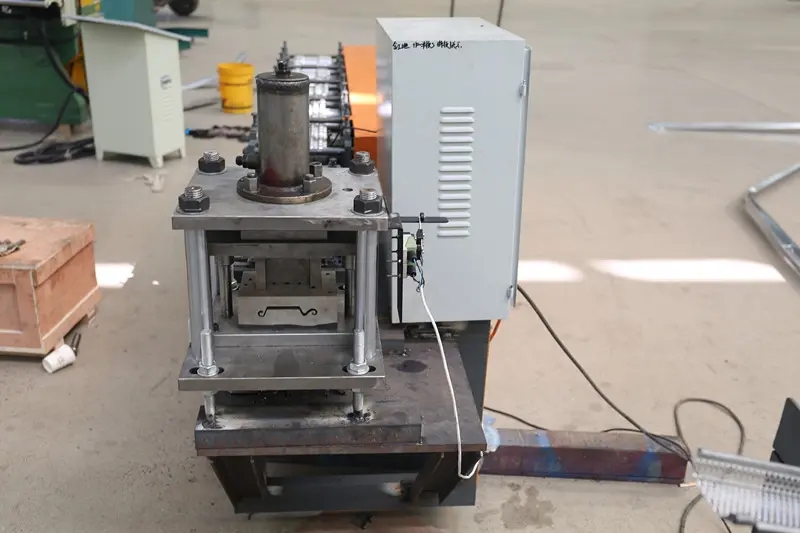

What is a Corrugated Steel Panel Roll Forming Machine?

A corrugated steel panel roll forming machine is an automated system designed to shape coiled steel into corrugated panels through a series of precise molding processes. The machine takes in flat steel sheets or coils and, through a set of rollers, shapes them into a specified profile. This manufacturing process involves several stages, including decoiling, roll forming, cutting, and sometimes the addition of protective coatings which enhance the durability and longevity of the panels.

Advantages of Using Corrugated Steel Panels

1. Strength and Durability Corrugated steel panels are highly resilient against extreme weather conditions, making them suitable for various applications, from residential roofing to large-scale industrial buildings. Their structural integrity offers enhanced resistance to bending and flexing compared to flat steel sheets.

2. Lightweight Nature The design of corrugated panels allows for significant weight savings without compromising strength. This can lead to reduced transportation costs and easier handling during installation.

3. Cost-Effective The use of roll forming technology ensures that a minimal amount of material is wasted during production. Additionally, the quick installation process decreases labor costs, contributing to overall economic efficiency.

4. Aesthetic Appeal With the availability of various colors and finishes, corrugated steel panels can be customized to meet the aesthetic needs of different architectural designs. This versatility makes them suitable for both commercial and residential applications.

5. Sustainability Steel is one of the most recycled materials globally. The production process of corrugated steel panels can utilize recycled steel, making them an environmentally friendly choice for construction projects.

How the Roll Forming Process Works

The roll forming process begins with the feeding of a steel coil into the machine, which is unwound using a decoiler. The flattened steel then passes through a series of rollers, each designed to progressively shape the steel into a corrugated form. The precision of each roller is crucial as it ensures that the dimensions and profiles are consistent throughout the production run. Finally, the formed panels are cut to the required lengths, ready for shipping and installation.

Innovations in Roll Forming Technology

Recent advancements in roll forming technology have further enhanced the efficiency and effectiveness of corrugated steel panel production. Automated systems equipped with computer numerical control (CNC) allow for greater precision and quicker adjustments to changing specifications. This innovation not only boosts production capacity but also minimizes human error during the manufacturing process.

Conclusion

In conclusion, the corrugated steel panel roll forming machine stands at the forefront of modern construction technology, delivering products that meet the increasing demands for durability, efficiency, and aesthetic value. As the construction industry continues to evolve, the roll forming technology will play a crucial role in providing innovative solutions that cater to a wide range of building needs. With its numerous advantages, corrugated steel panels manufactured through advanced roll forming processes are set to remain a key component of sustainable and efficient construction in the years to come.