The Evolution of Corrugated Sheet Roof Roll Forming Lines

In the ever-evolving landscape of construction and manufacturing, corrugated sheet roofing has emerged as a popular choice due to its durability, aesthetic appeal, and cost-effectiveness. To meet the rising demand for this versatile roofing material, advancements in technology have led to the development of efficient corrugated sheet roof roll forming lines. This article delves into the intricacies of these production lines, their advantages, applications, and future trends.

Understanding Roll Forming

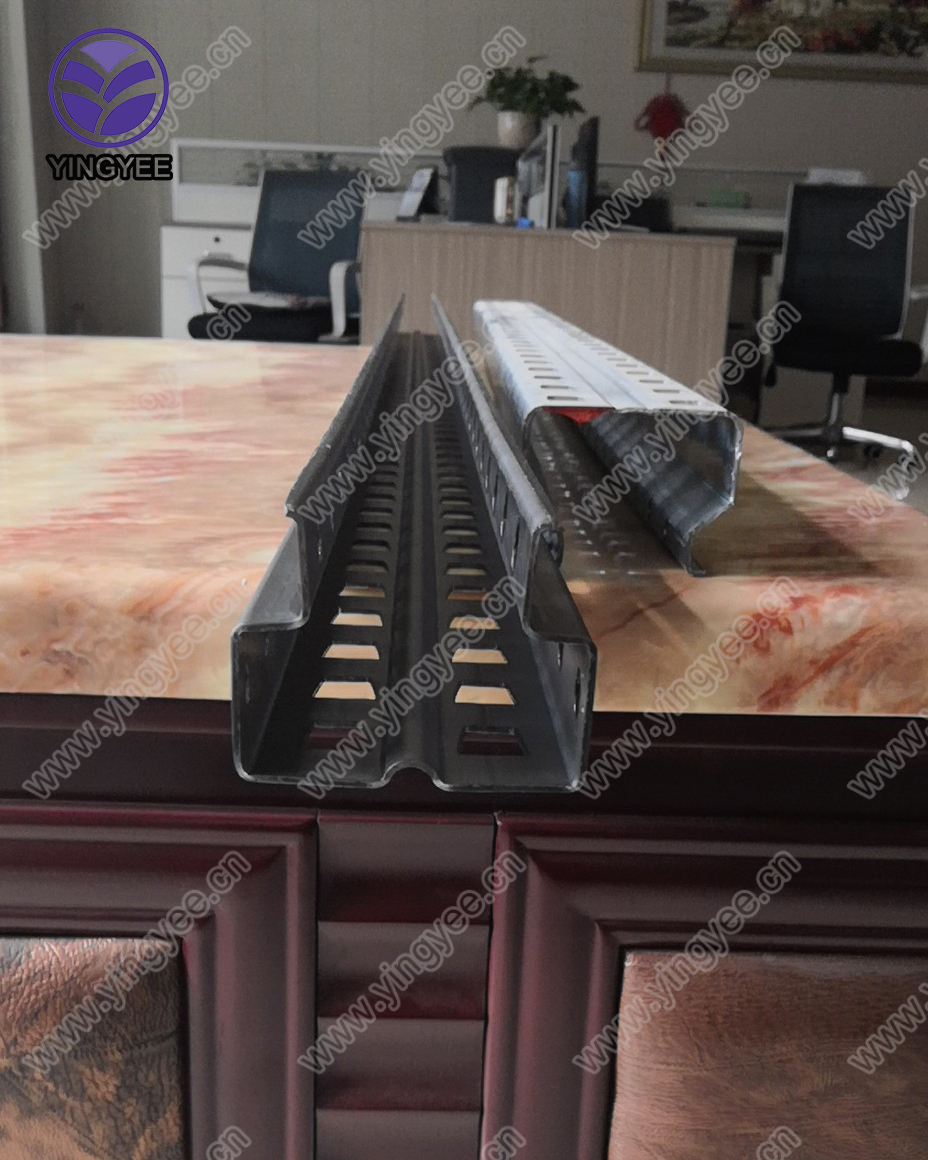

Roll forming is a continuous bending process in which sheet metal is gradually shaped into the desired profile through multiple passes. A corrugated sheet roof roll forming line specifically alters flat metal sheets—usually made of steel or aluminum—into a series of alternating high and low profiles, creating the corrugated effect. This process not only enhances the material's structural integrity but also improves its resistance to environmental factors.

Components of a Corrugated Sheet Roof Roll Forming Line

A typical corrugated sheet roof roll forming line comprises several key components

1. Uncoiler This station unwinds large coils of sheet metal, providing the raw material for the process.

2. Feeding System The metal sheets are fed into the roll forming machine with precision. Accurate feeding ensures uniformity in the final product.

3. Roll Forming Machine This is the heart of the production line, where the flat sheets are shaped into corrugated profiles. The machine consists of multiple rollers positioned in such a way that the sheet is continuously formed into its final shape as it passes through.

4. Cutting Station Once the sheets are shaped, they need to be cut to the desired length. The cutting station can be integrated with the roll forming machine for automatic cutting as sheets emerge.

Advantages of Using Corrugated Sheet Roof Roll Forming Lines

1. Cost Efficiency The automation of the roll forming process significantly reduces labor costs. Moreover, the ability to produce sheets in bulk leads to lower material costs.

2. High Production Capacity Modern roll forming lines can produce a considerable volume of corrugated sheets in a shorter timeframe, meeting the demands of large-scale construction projects.

3. Quality Control With automated processes and precise engineering, the consistency and quality of the corrugated sheets produced are top-notch. Advanced technology also allows for defect detection during production.

4. Versatility Roll forming lines can be easily adjusted to produce various profiles, allowing manufacturers to cater to different architectural designs and requirements.

Applications of Corrugated Sheet Roofing

Corrugated sheet roofing finds applications across multiple sectors. It is widely used in residential, commercial, and industrial buildings, providing an effective roofing solution that is both functional and aesthetically pleasing. Additionally, its lightweight and strong structure make it suitable for agricultural buildings, warehouses, and even temporary installations like event tents.

Future Trends

The future of corrugated sheet roof roll forming lines is promising, driven by technological advancements. The integration of Industry 4.0 concepts, such as IoT sensors and data analytics, is set to optimize production processes further. Smart machines can monitor performance in real-time, predict maintenance needs, and improve operational efficiencies.

Moreover, as sustainability becomes increasingly important, manufacturers are exploring eco-friendly materials and processes, enhancing the green credentials of corrugated sheet roofing.

Conclusion

The development of corrugated sheet roof roll forming lines marks a significant leap in manufacturing efficiency and product quality. As the demand for robust, versatile roofing solutions continues to grow, these production lines will play a crucial role in shaping the future of construction. Embracing technological advancements and sustainable practices will ensure that corrugated roofing remains a staple in the industry for years to come.