Understanding the Corrugated Sheet Rolling Machine

In recent years, the construction and manufacturing industries have seen significant advancements in technology, and one such innovation is the corrugated sheet rolling machine. This machine plays an essential role in the production of corrugated metal sheets, which are widely used for roofing, siding, and various other applications due to their strength, durability, and lightweight nature.

What is a Corrugated Sheet Rolling Machine?

A corrugated sheet rolling machine is a specialized piece of equipment designed to create corrugated metal sheets from flat metal coils. These machines process various materials, including galvanized steel, aluminum, and stainless steel, converting them into sheet forms that exhibit a wavy pattern. This specific shape not only enhances the aesthetic appeal of the sheets but also increases their structural integrity and performance in various environmental conditions.

Working Principle

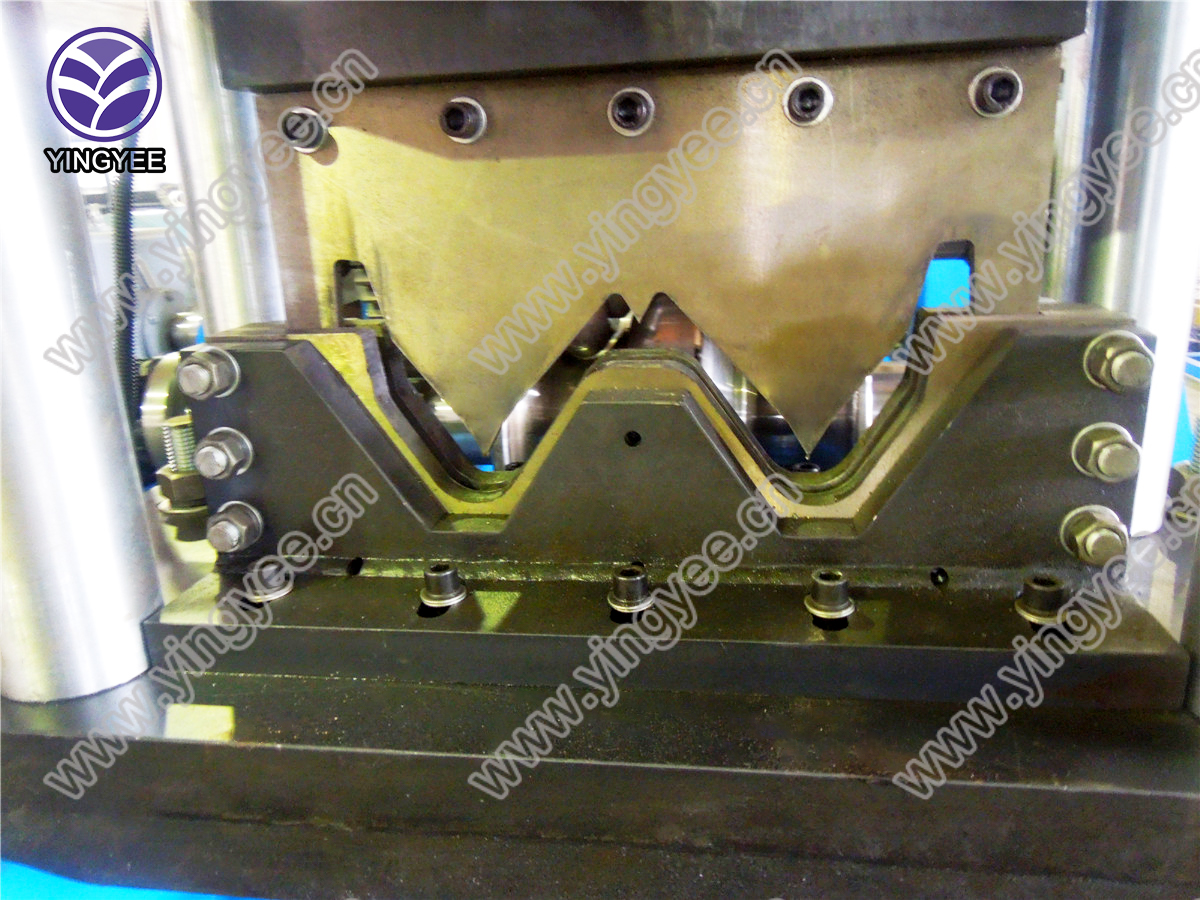

The operation of a corrugated sheet rolling machine involves several key steps. First, a flat metal coil is unrolled and fed into the machine. As the coil enters the machine, it passes through rollers that progressively shape the sheets. The rollers are strategically designed to create the desired profile of the corrugated sheet—usually consisting of alternating peaks and valleys.

During this process, the machine maintains precise control over various parameters, including speed, pressure, and thickness. This ensures that the final product meets the exact specifications required for different applications. Once the corrugated sheets are formed, they are cut to the desired length and can be further processed or packaged for distribution.

Advantages of Using a Corrugated Sheet Rolling Machine

1. Efficiency and Speed Modern corrugated sheet rolling machines are equipped with high-speed operations, significantly reducing production time and increasing overall efficiency. This is particularly beneficial for large-scale projects that require mass quantities of corrugated sheets.

2. Customization These machines can often be adjusted to produce sheets with varying profiles, thicknesses, and lengths, catering to the specific needs of different clients and projects. Customization options allow manufacturers to respond quickly to market demands.

3. Cost-Effectiveness By streamlining the manufacturing process, corrugated sheet rolling machines can lower production costs. This cost savings can be passed on to consumers, making corrugated sheets an attractive option for various applications.

4. Quality Control Advanced technologies incorporated in modern machines allow for increased precision in the corrugation process, resulting in high-quality sheets with uniform strength and durability. This quality control is crucial in industries where safety and longevity are paramount.

5. Versatility Corrugated sheets produced by these machines are used in several applications, from residential roofing to industrial buildings and agricultural structures. Their versatility makes them a staple in construction and manufacturing sectors.

Conclusion

The corrugated sheet rolling machine is an invaluable asset in the modern manufacturing landscape. With its ability to produce high-quality, durable, and aesthetically pleasing corrugated sheets efficiently, it meets the growing demands of various industries. As technology continues to evolve, we can expect further advancements in design and capabilities, ensuring that these machines remain at the forefront of construction and manufacturing innovations.

In summary, the corrugated sheet rolling machine is not just a vital tool for producing corrugated sheets; it represents the intersection of technology, efficiency, and adaptability in meeting the needs of a rapidly changing market. Whether for roofing, siding, or insulation applications, the impact of this machine cannot be overstated, and its relevance will only grow as industries seek sustainable and cost-effective solutions to meet the challenges of the future.