Understanding the Corrugated Sheet Rolling Machine

The manufacturing of corrugated sheets is integral to various industries, particularly construction and packaging, due to their sturdy yet lightweight nature. The heart of this production process lies in the corrugated sheet rolling machine, a sophisticated piece of equipment designed to efficiently create sheets that boast impressive structural integrity and durability.

What is a Corrugated Sheet Rolling Machine?

A corrugated sheet rolling machine is an industrial tool designed to form metal sheets into corrugated shapes. These machines are built to convert flat sheets of metal, typically made from materials such as galvanized steel, aluminum, or stainless steel, into desired corrugated profiles. The process involves several stages, including feeding the flat sheets into the machine, rolling them through specifically designed rollers, and cutting them to predetermined lengths.

Working Principle

The operation of a corrugated sheet rolling machine can be broken down into a series of steps

1. Material Feeding The first step involves loading the flat sheets of metal into the machine. This is usually done manually or via a feeding system that ensures the sheets are accurately aligned.

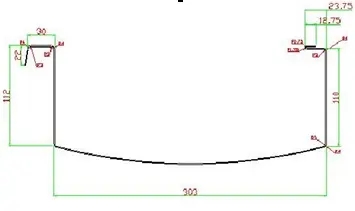

2. Rolling Process Once the metal sheets are fed into the machine, they are passed through rollers that gradually bend and shape the sheets into the desired corrugated form. The design of these rollers is critical as they determine the final shape and depth of the corrugation. Typically, manufacturers adjust the roller settings to achieve various corrugation types, widths, and heights, allowing for versatility in the products being manufactured.

3. Cutting and Finishing After the sheets are shaped, they are cut to length using a cutting mechanism integrated into the machine. Some advanced models also incorporate additional features for edge trimming and surface treatment to enhance the finished product's quality.

Advantages of Corrugated Sheet Rolling Machines

1. Efficiency Modern corrugated sheet rolling machines are designed for high throughput, enabling manufacturers to produce large volumes of corrugated sheets in a short time.

2. Versatility These machines can be adjusted to produce different types of corrugated profiles, making them suitable for various applications, including roofing, wall cladding, and packaging materials.

3. Cost-Effectiveness By automating the production process, manufacturers can reduce labor costs and material waste, ultimately leading to higher profitability.

4. Quality Assurance With precise control over the manufacturing process, including roller pressure, speed, and temperature, manufacturers can ensure consistent quality in the finished products. This is crucial for applications where structural integrity is key.

5. Durability The materials traditionally used (like galvanized steel) in corrugated sheets produced by this machine are known for their strength and longevity, making them an ideal choice for both industrial and residential applications.

Applications of Corrugated Sheets

Corrugated sheets have a wide range of applications across various sectors

- Construction In the construction industry, corrugated sheets are commonly used for roofing and cladding, thanks to their lightweight yet sturdy nature, which can withstand harsh weather conditions. - Packaging Corrugated sheets are also extensively used in the packaging industry, particularly in making boxes and containers that require robustness and protection during transportation.

- Decorative Installations The aesthetic appeal of corrugated sheets has led to their use in interior design and art installations, where they serve both functional and decorative purposes.

Conclusion

The corrugated sheet rolling machine plays an essential role in the production of highly demanded corrugated sheets, providing an optimal solution for various industrial needs. As technology advances, these machines continue to evolve, offering enhanced precision, speed, and efficiency. Manufacturers who invest in high-quality corrugated sheet rolling machines are likely to benefit from reduced operational costs, increased production capacity, and the ability to meet the ever-changing demands of the market. In a world where versatility and durability are paramount, the corrugated sheet rolling machine remains a vital piece of equipment in manufacturing industries worldwide.