The Evolution and Significance of Corrugated Sheet Forming Machines

In the world of manufacturing, the corrugated sheet forming machine plays a crucial role in transforming raw materials into versatile, sturdy products used in various applications. These machines are pivotal in producing corrugated sheets, which are characterized by their wavy or fluted structure that provides exceptional strength and durability. This article explores the evolution, significance, and applications of corrugated sheet forming machines in the modern industrial landscape.

The history of corrugated sheets dates back to the early 19th century when they were first used as a packaging material. The introduction of corrugated sheet forming machines revolutionized the production process. Initially, manufacturing was labor-intensive and required significant manual input. Over time, technological advancements led to the development of semi-automated and fully automated machines capable of producing corrugated sheets at high speeds and consistent quality. These machines are now equipped with computer numerical control (CNC) technology, which allows for precision engineering and customization, catering to specific client requirements.

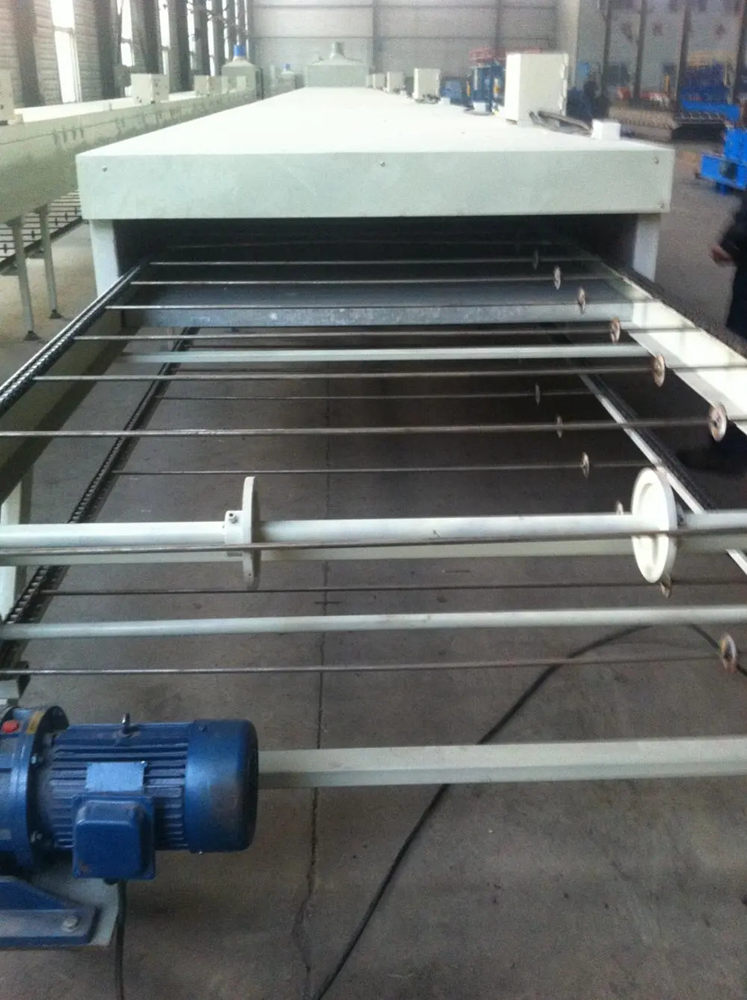

The primary function of a corrugated sheet forming machine is to convert flat sheets of paper or other materials into a corrugated design. The process typically involves several stages feeding the raw material, forming the corrugated structure, and cutting the sheets to the desired size. Modern machines can handle various materials, including recycled paper, which contributes to sustainability efforts within the industry. The ability to produce different flute sizes and types allows manufacturers to create sheets that meet specific strength requirements for their products.

One of the most significant advantages of corrugated sheet forming machines is their efficiency. Compared to traditional methods, these machines significantly reduce production time and labor costs, making them an invaluable asset to manufacturers. Furthermore, the production of corrugated sheets is environmentally friendly. Many machines are designed to minimize waste, and the use of recyclable materials aligns with global sustainability initiatives.

The applications of corrugated sheets are vast and varied. They are widely used in packaging, particularly for shipping boxes, where strength and lightweight properties are essential. The e-commerce boom has further increased the demand for corrugated packaging solutions, prompting manufacturers to invest in advanced forming machines to keep pace with market needs. In addition to packaging, corrugated sheets are also used in construction, automotive parts, and even decorative items, showcasing their versatility.

Moreover, as the market evolves, so too do the technologies powering corrugated sheet forming machines. Innovations such as digital printing capabilities and enhanced automation are becoming standard features. This allows manufacturers not only to produce high-quality sheets but also to customize them with branding or specific designs, enhancing their marketability.

In conclusion, corrugated sheet forming machines are an essential component in the realm of manufacturing, significantly impacting efficiency, sustainability, and product versatility. As technology continues to advance, these machines will likely evolve further, driving innovation in various industries and addressing the ever-changing demands of consumers. The combination of strength, lightness, and cost-effectiveness makes corrugated sheets an enduring choice for manufacturers, ensuring the corrugated sheet forming machine remains a vital tool in the modern production landscape.