The Evolution and Significance of Corrugated Roof Tile Making Machines

In the realm of construction and architectural design, the importance of roofing materials cannot be overstated. Among various roofing options, corrugated roof tiles have garnered considerable attention owing to their durability, cost-effectiveness, and aesthetic appeal. The production of these tiles has been revolutionized through the introduction of advanced machinery, specifically designed for corrugated roof tile making. This article explores the significance, advantages, and technological advancements of corrugated roof tile making machines.

Understanding Corrugated Roof Tiles

Corrugated roof tiles are distinguished by their wavy or ridged structure, which not only adds to their visual appeal but also enhances their functionality. These tiles are primarily made from materials such as metal, fiberglass, or polymer, contributing to their strength and weather resistance. The unique design of corrugated tiles allows for effective rainwater drainage while reducing the risk of leaks and damage, making them ideal for various climates.

The Role of Machinery in Production

Historically, roofing materials were produced manually, which often led to inconsistencies in product quality and increased labor costs. The advent of corrugated roof tile making machines marked a significant turning point in the roofing industry. These machines automate the manufacturing process, ensuring uniformity and precision in the production of tiles.

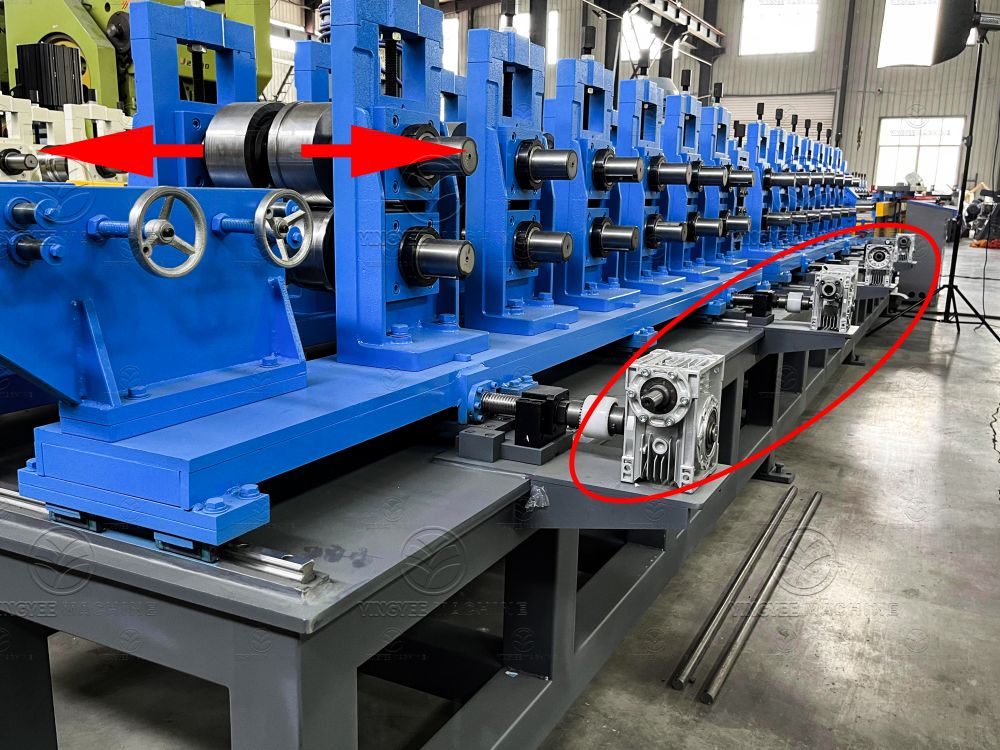

A typical corrugated roof tile making machine operates by feeding raw materials into a production line, where they undergo various steps including molding, heating, and cutting. Advanced machines are equipped with computer-controlled systems that enhance their efficiency, allowing for high-speed production without compromising quality. This automation not only reduces manufacturing time but also minimizes human error, resulting in high-quality tiles that meet stringent industry standards.

Key Benefits of Corrugated Roof Tile Making Machines

1. Efficiency and Productivity One of the primary benefits of using automated machines for tile production is the significant increase in efficiency. These machines can produce a large volume of tiles in a short period, which is crucial for meeting market demands, especially in the construction sector.

2. Cost-Effectiveness While the initial investment in corrugated roof tile making machines may be substantial, the long-term savings achieved through reduced labor costs and higher production rates make them an economically viable solution. Moreover, manufacturers can achieve a lower cost per unit, thereby increasing their market competitiveness.

3. Customization Modern corrugated roof tile making machines offer the capability to customize tile sizes, shapes, and colors according to the customer's specifications. This flexibility has made it easier for architects and construction professionals to implement unique designs, aligning with contemporary trends in building aesthetics.

4. Quality Control Quality assurance is pivotal in the construction industry. Automated machines are designed with advanced sensors and controls that monitor the production process in real-time. This ensures that each tile produced meets predetermined specifications, significantly reducing the risk of defects and enhancing overall product reliability.

5. Eco-Friendly Options As sustainability becomes a growing concern, many manufacturers have begun producing eco-friendly corrugated roof items. Modern machines can work with recyclable materials and incorporate energy-efficient technologies, reducing the environmental footprint of roofing production.

Future Trends in Corrugated Roof Tile Manufacturing

The evolution of corrugated roof tile making machines continues with the integration of smart technologies. Innovations such as IoT (Internet of Things) connectivity and AI (Artificial Intelligence) could play significant roles in optimizing production processes and predictive maintenance practices. These advancements can further increase efficiency and minimize downtime, ultimately leading to better resource management in manufacturing.

Additionally, as the global construction market evolves, the demand for lightweight, durable, and energy-efficient roofing materials is expected to rise. Manufacturers must stay abreast of material advancements and design trends to remain competitive. Incorporating automated solutions into production can aid in meeting these demands effectively.

Conclusion

The innovation in corrugated roof tile making machines has fundamentally transformed the roofing industry, bringing forth numerous benefits such as efficiency, cost-effectiveness, and high-quality production. As technology continues to evolve, these machines will undoubtedly play a pivotal role in shaping the future of roofing solutions, allowing for greater creativity, sustainability, and performance in construction. For architects, builders, and consumers alike, the advantages offered by these machines signify a remarkable step forward in roofing technology.