The Role of Corrugated Roll Forming Machines in Modern Manufacturing

In the realm of modern manufacturing, the need for efficient and cost-effective production methods is paramount. One of the technologies that has revolutionized the production of sheet metal components is the corrugated roll forming machine. This specialized equipment is designed to create corrugated sheets and profiles from metal sheets through a continuous bending process. With applications ranging from construction to packaging, the significance of corrugated roll forming machines cannot be overstated.

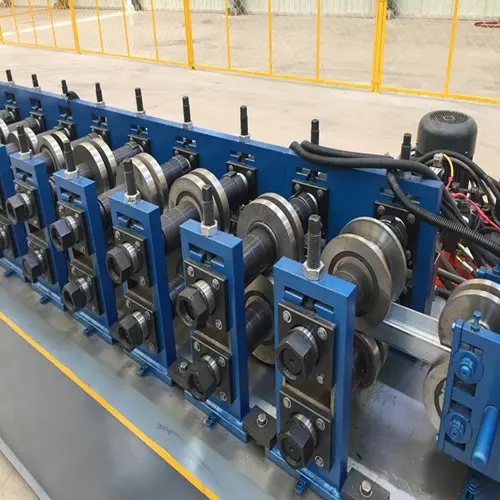

What is a Corrugated Roll Forming Machine?

A corrugated roll forming machine is a piece of industrial equipment that transforms flat metal sheets into corrugated shapes, which enhance strength and rigidity. This machine consists of multiple rollers, each progressively shaping the metal as it passes through. The process begins with feeding a flat sheet of metal into the machine, where it is gradually shaped into corrugated profiles. These profiles provide structural stability and can be customized to various dimensions and specifications based on the end-use requirements.

Applications in Various Industries

1. Construction Industry One of the primary uses of corrugated roll forming machines is in the construction sector. Corrugated metal panels are widely used for roofing and wall cladding due to their durability, lightweight nature, and ability to effectively channel water. The corrugated profile also provides additional strength without significantly increasing material costs.

2. Packaging Industry Corrugated materials are essential in packaging applications. They offer excellent protection for products during transit and storage. Manufacturers utilize corrugated sheets created by roll forming machines for boxes, pallets, and other packaging solutions. The ability to produce custom sizes and shapes makes these machines invaluable in the packaging industry.

3. Automotive and Appliance Industries In automotive manufacturing, corrugated roll forming machines help create lightweight yet sturdy components used in vehicle frames and body parts. The aerospace sector also benefits from these machines, producing components that require specific strength-to-weight ratios.

4. Furniture Manufacturing Some furniture designs incorporate corrugated materials for aesthetic and functional purposes. Roll formed components are often used in the production of partitions, tables, and seating arrangements, providing both style and utility.

Advantages of Using Corrugated Roll Forming Machines

The benefits of utilizing corrugated roll forming machines are manifold. Firstly, they allow for high production speeds, meaning manufacturers can meet large order demands while maintaining quality. Secondly, these machines are known for their efficiency in material usage, generating minimal waste during the production process.

The consistency in quality that these machines deliver is another significant advantage. Automated systems ensure that each piece is produced to the same specifications, reducing the margin for error. Additionally, the flexibility of roll forming technology enables manufacturers to quickly adjust the setup for different profiles, accommodating varying customer needs without significant downtime.

Conclusion

In conclusion, corrugated roll forming machines are a vital asset in modern manufacturing, providing solutions across diverse industries. Their ability to produce strong, lightweight, and aesthetically pleasing components efficiently makes them indispensable in today's fast-paced production environment. As technology advances and industries continue to evolve, the role of corrugated roll forming machines will undoubtedly expand, further enhancing productivity and innovation in manufacturing processes worldwide. Understanding their functionality and versatility can help businesses leverage these machines effectively to remain competitive in their respective markets.