The corrugated deck cold bending machine is a marvel of modern engineering that combines efficiency and precision, addressing the needs of industries requiring robust metal deck systems. Much more than just machinery, it embodies a sea change in how metal decking is constructed, promising enhanced durability, safety, and cost efficiency to builders worldwide.

What sets the corrugated deck cold bending machine apart is its meticulous design tailored to tackle the specific challenges associated with forming strong and reliable corrugated decks. Industry experts highlight that advanced machines in this category are equipped with cutting-edge software, allowing for precise modulation of bending angles, depth, and alignment as per the bespoke needs of a project.

From an experiential perspective, contractors and builders who have incorporated this technology into their construction processes often report a significant increase in workflow efficiency. The machine operates with automated feeding systems that reduce manual handling, thus minimizing errors. It processes metal sheets rapidly while ensuring consistent quality, markedly reducing production time compared to traditional bending techniques.

Professionally,

expertise in cold bending technology extends beyond just operational usage. Engineers and manufacturers who design these machines possess a deep understanding of materials science, recognizing how different metal compositions will respond under various conditions of stress and temperature. The precise calibration of these machines ensures that each corrugation introduces no material fatigue or structural weaknesses, which is crucial for maintaining the safety and longevity of the constructed decking.

Authoritativeness comes from an industry-wide recognition of these machines as critical components in construction technologies. Suppliers and manufacturers of corrugated deck cold bending machines often partner with major construction firms, providing not only the machinery but also extensive training and support services. This reinforces the authority and reliability of the machine as an integral part of the construction process.

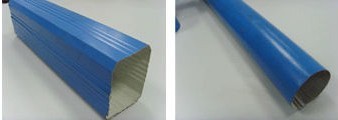

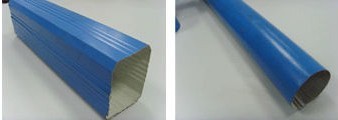

corrugated deck cold bending machine

Trustworthiness is perhaps the defining aspect of the corrugated deck cold bending machine's impact. For project managers, knowing that the machinery they rely on is built to the highest standards of craftsmanship and resilience instills confidence. When these machines are subjected to rigorous quality tests and comply with international standards, such as ISO certification, they earn their place as trusted assets in any construction arsenal.

Incorporating a corrugated deck cold bending machine into a construction project can significantly elevate the quality of the final build. By ensuring that every corrugation is perfect, these machines help in producing decks that provide an enhanced anti-slip surface, optimized load distribution, and improved aesthetic appeal. This precision directly translates into a safer build, with decks that are capable of withstanding environmental stresses much better than those built using outdated methods.

In real-world applications, the success stories abound. Companies have reported improved project turnaround times and heightened customer satisfaction due to the uniformity and precision of the building materials produced by these machines. The consistent quality directly translates into fewer repairs and maintenance requirements post-construction, thereby offering long-term economic benefits.

Looking to the future, the development of even more refined corrugated deck cold bending machines seems inevitable. Current trends include the integration of IoT technologies and machine learning, allowing for predictive maintenance and enhanced user interfaces that further simplify operation. These advancements not only boost productivity but also set a new benchmark for quality and safety in the construction industry.

In conclusion, the corrugated deck cold bending machine is more than a tool—it’s a catalyst for efficiency and quality in modern construction. It represents a blend of engineering prowess, robust design, and unparalleled precision, aligning perfectly with the industry’s push towards smarter, safer, and more efficient building practices. Its unmatched capabilities offer a credible, expert-endorsed solution for diversified construction challenges, cementing its place as a cornerstone technology in the sector.