The Corrugated Roof Sheet Making Machine Revolutionizing the Construction Industry

In the modern construction industry, the demand for robust and cost-effective roofing solutions is at an all-time high. Among various options available, corrugated roof sheets have emerged as a popular choice due to their durability, lightweight nature, and aesthetic appeal. This increasing demand has given rise to advanced technologies, notably the corrugated roof sheet making machine, which plays a pivotal role in the production of these essential materials.

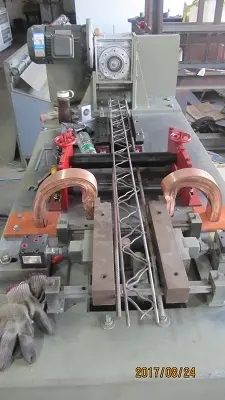

At its core, a corrugated roof sheet making machine is designed to efficiently produce corrugated sheets from various materials, primarily galvanized iron, aluminum, and PVC. The process begins with feeding raw metal sheets into the machine, where they undergo several stages of processing. These machines are equipped with advanced rollers that shape the flat metal sheets into corrugated patterns, enhancing their structural strength and resistance to harsh environmental conditions.

The design of corrugated roof sheet making machines varies, but most feature a user-friendly interface that allows operators to control parameters such as sheet thickness, width, and the size of the corrugations

. This flexibility enables manufacturers to tailor their products to meet specific project requirements, making them invaluable in diverse construction applications.Additionally, modern machines are often equipped with automated systems for cutting and stacking the finished sheets, streamlining the production process and significantly reducing labor costs. As a result, manufacturers can maintain high output levels while ensuring consistent quality, which is crucial for meeting the demands of large-scale construction projects.

Environmental considerations are also becoming increasingly important in the manufacturing process. Many corrugated roof sheet making machines now incorporate energy-efficient technologies and systems to minimize waste, contributing to a more sustainable production cycle. By utilizing recyclable materials and optimizing energy consumption, these machines help meet the growing need for sustainable building practices.

The applications of corrugated roof sheets are vast. They are widely used in residential, commercial, and industrial buildings, offering protection against the elements while providing an aesthetically pleasing finish. Moreover, their lightweight nature facilitates easier installation, making them a preferred choice among builders and contractors.

As the construction industry continues to evolve, the demand for high-quality corrugated roofing solutions is expected to grow. The corrugated roof sheet making machine stands at the forefront of this transformation, enabling manufacturers to meet the growing needs of the market efficiently and sustainably.

In conclusion, the invention and advancement of corrugated roof sheet making machines have revolutionized the roofing industry. By combining efficiency, customization, and sustainability, these machines ensure that builders have access to reliable materials, ultimately contributing to safer and more resilient structures in our communities.