The Composite Floor Deck Roll Forming Machine Revolutionizing Construction

In the ever-evolving landscape of construction technology, the composite floor deck roll forming machine stands out as a pivotal innovation. This advanced machinery is specifically designed to create high-quality composite floor deck systems, which are essential in modern building projects for their strength, efficiency, and cost-effectiveness.

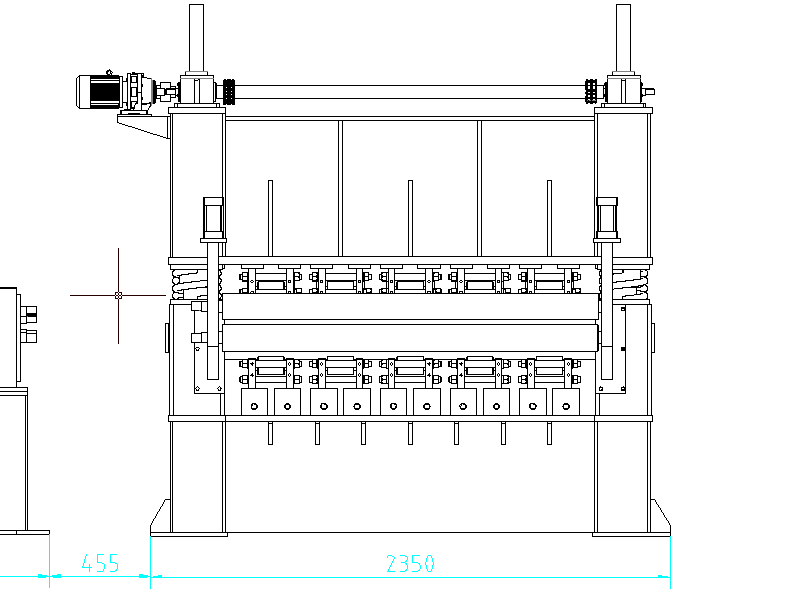

Composite floor decks are an integral part of today's construction industry. They are used to support concrete slabs and provide a robust platform for various building structures. The roll forming machine utilizes a continuous process to shape metal sheets, typically made of galvanized steel or other materials, into predetermined profiles that enhance structural integrity and load-bearing capabilities.

One of the primary advantages of using a composite floor deck roll forming machine is the efficiency it brings to the production process. These machines automate the forming of steel sheets, significantly reducing manual labor and increasing output speed. As a result, construction projects can proceed at a faster pace, allowing for timely completion and reduced labor costs.

Moreover, the versatility of these machines allows for the production of various deck profiles to meet specific architectural and structural requirements

. Whether it's for residential, commercial, or industrial applications, the flexibility to adjust the forming process means that builders can achieve custom designs without sacrificing quality.

Another significant benefit of composite floor deck systems is their contribution to sustainability in construction. The materials used are often recyclable, and the lightweight nature of the decks reduces the overall dead load of buildings, leading to lower energy consumption in transportation and installation. This not only helps in cutting costs but also renders projects more environmentally friendly.

Furthermore, incorporating a composite floor deck roll forming machine into the production workflow streamlines quality control. Modern machines are equipped with advanced technologies that monitor parameters during the forming process, ensuring that the final product meets stringent quality standards. This reduces the likelihood of defects and enhances the overall safety of the structures being built.

As the construction industry continues to face challenges related to efficiency, sustainability, and cost management, the composite floor deck roll forming machine represents a forward-thinking solution. Its ability to deliver high-quality products quickly and sustainably positions it as an essential tool for builders aiming to stay competitive in today's market.

In conclusion, the composite floor deck roll forming machine is not just a piece of machinery; it is a game-changer in the construction industry. With its efficiency, versatility, and contribution to sustainability, it plays a crucial role in shaping the future of building practices and addressing the demands of a rapidly changing world.