Understanding Composite Floor Deck Forming Machinery An Essential Tool in Modern Construction

In the realm of modern construction, efficiency, durability, and cost-effectiveness are paramount. One of the most significant innovations in this field is the composite floor deck forming machinery. This specialized equipment plays a crucial role in the construction of composite floor decks, which are widely used in commercial buildings, industrial facilities, and multi-story residential projects. This article delves into the intricacies of composite floor deck forming machinery, its operation, benefits, and its impact on the construction industry.

What is Composite Floor Decking?

Composite floor decking refers to a type of flooring system that incorporates a combination of materials to achieve enhanced strength and performance. Typically composed of steel and concrete, composite floor decks are designed to support loads and provide excellent structural integrity. The steel deck acts as a permanent form and serves as tensile reinforcement for the concrete slab poured on top. This composite action results in a lightweight yet robust flooring solution that is both efficient and economical.

The Role of Forming Machinery

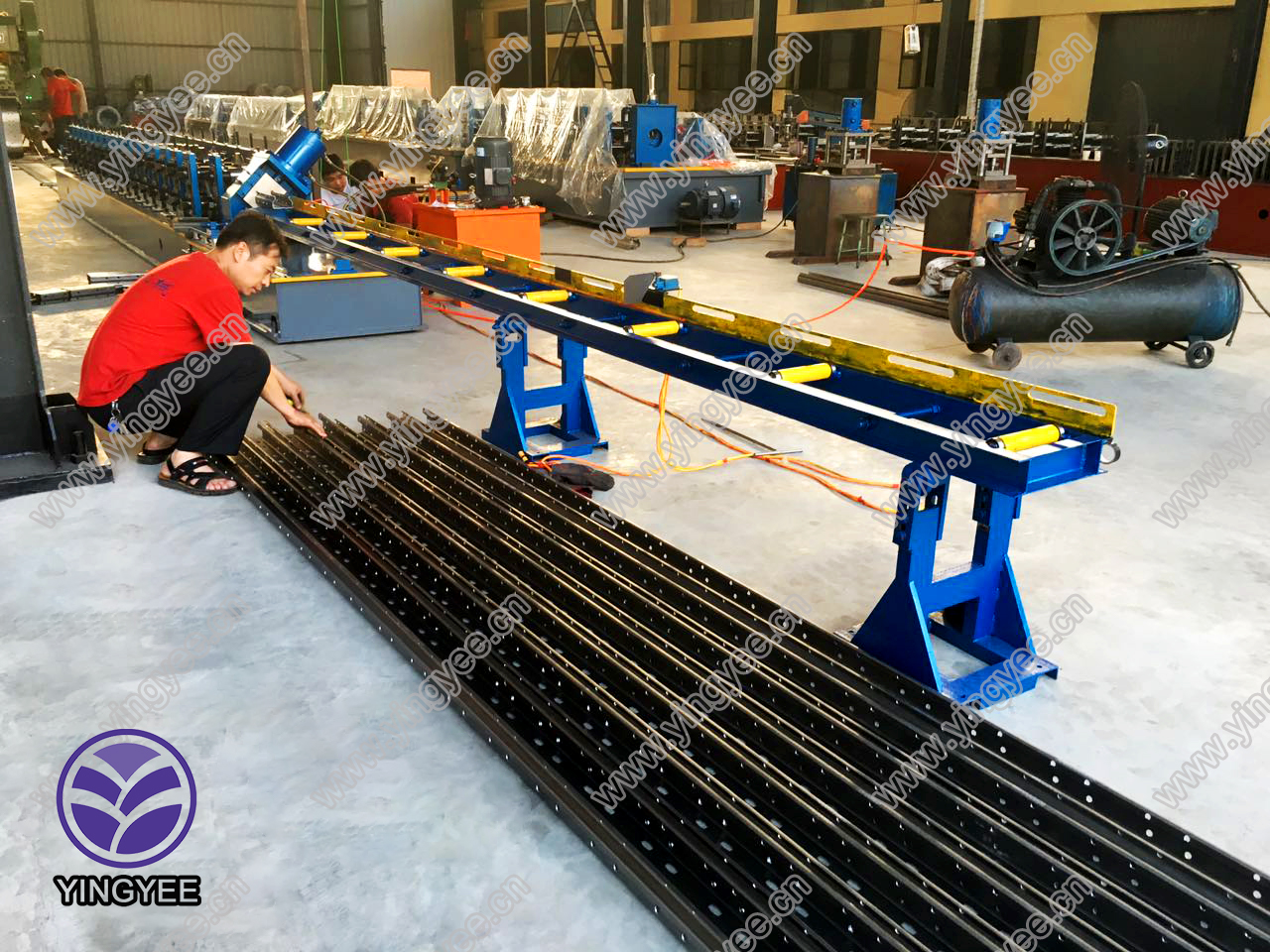

Composite floor deck forming machinery is specifically designed to produce the steel decking that forms the foundation of the composite floor system. These machines are equipped with advanced technology to ensure precision manufacturing, thus meeting the demanding requirements of modern construction projects. Here are the key functions of the forming machinery

1. Roll Forming The machinery utilizes a roll forming process to shape flat steel sheets into the desired profiles for the decking. This involves feeding coils of steel into the machine, which then conducts a series of bending operations to achieve the specified form.

2. Cutting Once the steel deck reaches the desired length, it is cut using automated cutting mechanisms, ensuring uniformity and accuracy across the production run. This capability is vital for maintaining consistent quality in construction projects.

3. Coating and Finishing Many composite floor deck forming machines also include options for applying protective coatings to the steel. These coatings can enhance rust resistance and improve the overall durability of the product, extending its lifespan in various environmental conditions.

4. Customization Modern forming machinery allows for customization in terms of profile depth, thickness, and width, enabling manufacturers to meet specific project requirements. This versatility is a significant advantage in the construction market.

Benefits of Using Composite Floor Deck Forming Machinery

Adopting composite floor deck forming machinery in construction processes yields numerous advantages

1. Efficiency The automated nature of forming machinery significantly speeds up production times. This efficiency translates to reduced lead times for construction projects, allowing builders to meet tight deadlines.

2. Cost-Effectiveness By streamlining the production process, companies can lower labor costs and material waste, resulting in overall cost savings. Additionally, the use of composite materials often reduces the amount of concrete required, further driving down expenses.

3. Quality Control With automated systems, manufacturers can achieve higher levels of precision and consistency in product quality. This level of control contributes to safer and more reliable structures, reducing the risks associated with construction defects.

4. Sustainability The use of steel in composite decking systems is sustainable as it is recyclable. Furthermore, the increased efficiency and reduced waste promoted by forming machinery contribute to greener construction practices.

Impact on the Construction Industry

The introduction of composite floor deck forming machinery has revolutionized the construction sector. Builders now have access to high-quality, durable flooring solutions that can be produced efficiently. This advancement has led to an increase in the adoption of composite systems in various applications, reshaping how buildings are designed and constructed.

As the construction industry continues to evolve, the role of composite floor deck forming machinery will undoubtedly grow. With ongoing advancements in technology and manufacturing processes, future iterations of this machinery promise to deliver even greater efficiency, versatility, and sustainability.

Conclusion

Composite floor deck forming machinery stands as a testament to the progress and innovation within the construction industry. By leveraging advanced technology to produce high-quality decking solutions, this machinery not only enhances project efficiency but also aligns with contemporary demands for sustainability and cost-effectiveness. As builders and contractors seek to elevate their methods and materials, understanding and utilizing composite floor deck forming machinery will remain a cornerstone of modern construction practices.