Composite Floor Deck Forming Machinery Revolutionizing Construction

In the ever-evolving landscape of construction technology, composite floor deck forming machinery stands out as a pivotal innovation. This machinery is designed to streamline the process of creating composite floor decks, which are essential for modern building practices. These decks are not only lightweight and strong but also contribute to the overall energy efficiency and structural integrity of buildings. Understanding the significance of this machinery, its operations, and its advantages is crucial for industry professionals and stakeholders.

What is Composite Floor Decking?

Composite floor decks are a type of flooring system that combines a steel deck with a concrete topping. This integration allows for a robust structural solution that enhances the load-bearing capacity of floors, making them ideal for commercial buildings, warehouses, and other large structures. The steel provides tensile strength, while the concrete offers compressive strength, resulting in a durable and versatile flooring option.

The Role of Forming Machinery

Composite floor deck forming machinery plays a crucial role in the construction process. This equipment is responsible for shaping the steel deck into the desired profile, complete with ribs or grooves that enhance performance and improve the bonding surface for concrete. The accuracy and efficiency of this machinery are vital for ensuring high-quality decking that meets industry standards.

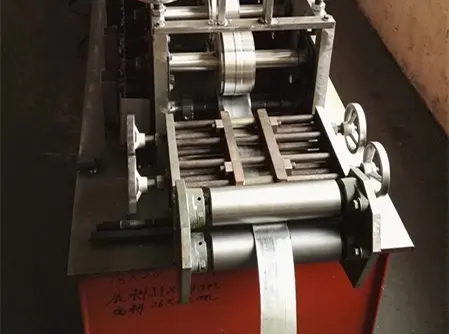

Typically, composite floor deck forming machinery consists of several components, including rollers, cutting systems, and hydraulic systems. The rollers are designed to shape the metal sheets that will be used to create the deck, while advanced cutting systems ensure that the edges of the formed deck are precise and uniform. Hydraulic systems provide the necessary force to bend and mold the steel, allowing for the flexibility required in various design applications.

Advantages of Composite Floor Deck Forming Machinery

The introduction of composite floor deck forming machinery has transformed construction efficiency and effectiveness. Here are some of the notable advantages it brings to the table

1. Increased Efficiency With automated machinery, the production speed of composite floor decks is significantly enhanced. This not only accelerates project timelines but also reduces labor costs, improving overall profitability for construction firms.

2. Precision Engineering Modern forming machinery utilizes advanced technology to achieve precise measurements and shapes. This accuracy is crucial for ensuring that the decks fit together perfectly on-site, minimizing waste and the need for costly adjustments.

3. Enhanced Strength and Durability The machinery allows for the consistent production of high-quality decks that meet stringent building codes and standards. This results in floors that are not only strong but also capable of withstanding various load conditions over time.

4. Customization Options Today’s forming machines can be programmed to create a variety of deck profiles, allowing architects and engineers to customize their designs according to specific project requirements. This flexibility fosters creativity in building design and functionality.

5. Sustainability Using composite materials improves the overall sustainability of buildings. The combination of steel and concrete reduces the need for extra support structures, leading to less material usage and a lower environmental impact during construction.

Conclusion

Composite floor deck forming machinery represents a significant advancement in the construction industry, embodying the fusion of technology and traditional building practices. Its ability to produce efficient, durable, and customizable decking solutions positions it as an integral component of modern construction methods. As buildings become more complex and the demand for innovative solutions increases, the importance of this machinery will only continue to grow, making it a key factor in delivering quality structures that stand the test of time. As the construction landscape continues to evolve, embracing such advancements will be crucial for industry leaders aiming to stay ahead in a competitive market.