The Evolution and Importance of Composite Floor Deck Forming Machinery

In the world of construction, efficiency and innovation play crucial roles in determining the success of a project. One significant advancement that has transformed the industry is the development of composite floor deck forming machinery. This technology not only streamlines the construction process but also enhances the structural integrity and sustainability of buildings.

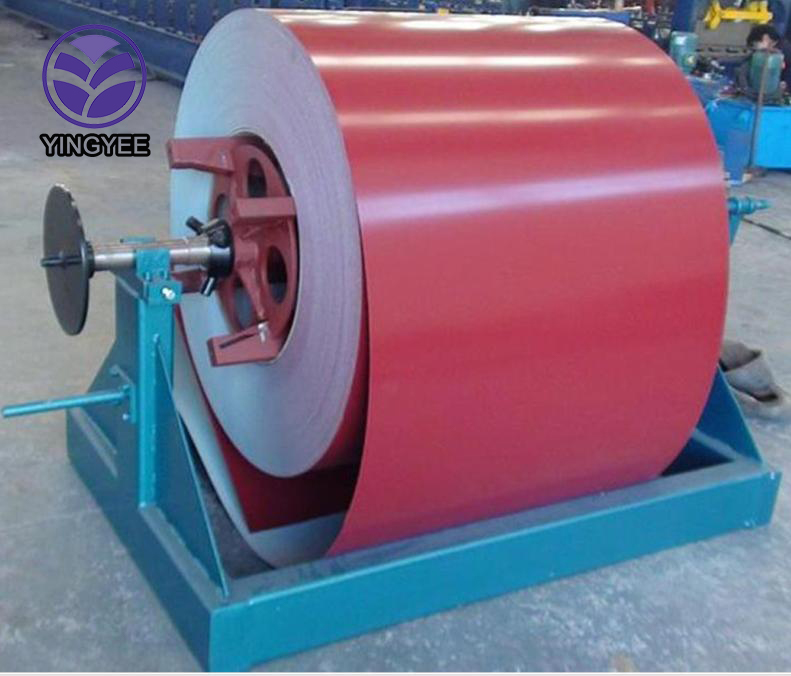

Composite floor decking refers to a flooring system that incorporates both steel and concrete, creating a strong and durable surface. The integration of these two materials allows for lighter structures that can support heavy loads, making them ideal for commercial and industrial buildings. The role of composite floor deck forming machinery is essential in producing the precast panels or decking sheets used in these applications.

One of the primary advantages of using composite floor deck forming machinery is the speed at which it can operate. Traditional methods of creating flooring systems often involve manual labor and extensive time commitments. In contrast, modern machinery can efficiently produce large quantities of decking in a fraction of the time. This not only reduces labor costs but also significantly shortens project timelines, allowing builders to move on to the next phase of construction more quickly.

Moreover, the precision and consistency offered by advanced forming machinery ensure high-quality products. Variations in thickness, weight, or dimensions can significantly impact the overall performance of a floor system. Automated machinery minimizes the risk of human error, ensuring that each panel is produced to exact specifications. This high level of accuracy contributes to better load distribution and enhances the overall stability of the structure.

Sustainability is another hallmark of composite floor deck forming machinery. In an age where environmental concerns are paramount, the ability to recycle and repurpose materials is invaluable. Manufacturers of composite decking often utilize scrap materials and byproducts from other construction processes, significantly reducing waste. Additionally, the lightweight nature of composite materials allows for reduced energy consumption during transportation and installation, aligning with modern construction practices focused on minimizing environmental impact.

Furthermore, the versatility of composite floor deck forming machinery cannot be overlooked. These machines can be tailored to produce various profiles and thicknesses, accommodating a wide range of design requirements and applications. From residential buildings to large-scale industrial facilities, the adaptability of this machinery makes it a vital tool in contemporary construction projects.

Looking ahead, the continued advancement of composite floor deck forming machinery is likely to shape the future of the construction industry. As technology evolves, manufacturers are expected to integrate smart automation and IoT capabilities into their machinery, further enhancing efficiency and monitoring capabilities. This evolution will not only improve production processes but also provide real-time data analytics to optimize operations.

In conclusion, composite floor deck forming machinery represents a significant leap forward in construction technology. Its ability to improve efficiency, ensure quality, promote sustainability, and offer versatility makes it an indispensable tool for modern builders. As the industry continues to evolve, the reliance on such innovative machinery will undoubtedly play a key role in shaping the skylines of tomorrow.