The Advancements and Impact of Composite Floor Deck Forming Machines

In recent years, the construction industry has witnessed a significant transformation driven by technological advancements. Among the crucial tools that have emerged is the composite floor deck forming machine. This innovative equipment plays a vital role in enhancing the efficiency, durability, and overall quality of building projects. By understanding the functionality, benefits, and future potential of composite floor deck forming machines, we can appreciate their contribution to modern construction.

Understanding Composite Floor Decking

Before delving into the specifics of forming machines, it is essential to understand what composite floor decking is. Composite floors are systems that integrate concrete and steel elements to create strong, lightweight structures. This type of flooring combines the compressive strength of concrete with the tensile strength of steel. The result is a robust platform that can support heavy loads, making it ideal for commercial and industrial applications. Composite floor decks are widely used in the construction of bridges, parking decks, and multi-story buildings, providing architects and engineers with a reliable solution for their designs.

The Role of Composite Floor Deck Forming Machines

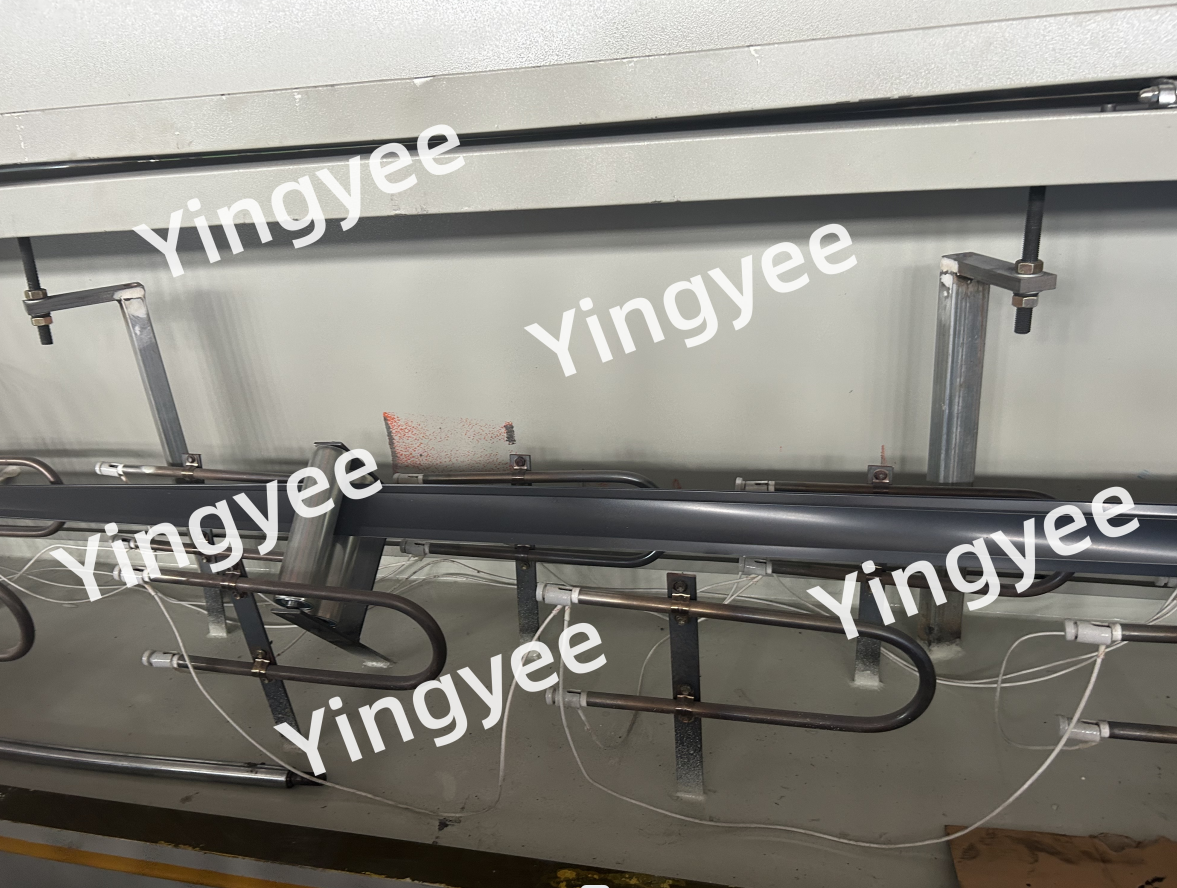

Composite floor deck forming machines are specialized tools designed to manufacture the steel decking that supports these composite systems. The machines automate the process of forming, cutting, and sometimes welding the steel sheets into various shapes and configurations necessary for different construction projects. This automation significantly reduces labor costs and minimizes human error, which has been a common issue in traditional manual methods.

These machines are capable of producing high volumes of decking in a fraction of the time it would take to create them manually. This increased efficiency not only speeds up construction timelines but also allows for greater flexibility in design. As projects become more complex, the ability to quickly adjust designs in response to client needs or regulatory changes becomes invaluable.

Key Benefits

1. Cost-Effective Production The automation provided by composite floor deck forming machines reduces the need for manual labor, lowering overall labor costs. Additionally, the ability to produce large quantities of decking quickly improves cost efficiency.

2. Improved Quality Control Automated machines ensure that each piece of deck is manufactured to precise specifications. This consistency in production leads to enhanced overall quality, reducing waste and the need for costly corrections later in the construction process.

3. Enhanced Safety By automating the forming process, workers are kept from engaging in repetitive and potentially dangerous tasks. This focus on safety not only protects the workforce but also reduces liability risks for construction companies.

4. Increased Design Versatility The ability to customize designs easily allows architects to be more creative in their projects. Whether dealing with unique site requirements or innovative architectural visions, forming machines can meet the demands of modern construction.

5. Sustainability Advantages By reducing material waste and improving energy efficiency during the manufacturing process, composite floor deck forming machines contribute positively to the environmental footprint of construction practices.

Future Trends

Looking ahead, the evolution of composite floor deck forming machines is poised for further innovation. Integration with advanced technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) will allow for even smarter manufacturing systems. These machines could potentially analyze performance data in real-time, optimizing production processes and maintenance schedules.

Moreover, as sustainability becomes an increasingly critical factor in construction, manufacturers are likely to focus more on eco-friendly materials and processes. Customized machines that can work with recycled or alternative materials will be instrumental in shaping the future of composite decking.

Conclusion

The advent of composite floor deck forming machines marks a pivotal moment in construction technology. By enhancing efficiency, improving safety, and promoting sustainability, these machines are not just tools but critical enablers of modern architectural visions. As the construction industry continues to embrace technological advancements, the importance of these machines will only grow, paving the way for more innovative, durable, and high-quality building solutions. Embracing this transformation will ultimately shape the way we build, leading to more resilient structures that meet the demands of a rapidly changing world.