Composite Floor Deck Forming Machines Revolutionizing Construction Efficiency

In the ever-evolving landscape of construction technology, the introduction of composite floor deck forming machines has significantly heightened efficiency and precision in building projects. These machines play a vital role in the production of composite floor decks, which are essential components of modern buildings. This article explores the functionalities, advantages, and broader implications of composite floor deck forming machines in the construction industry.

Understanding Composite Floor Decks

Composite floor decks are engineered systems that combine various materials, typically steel and concrete, to form a structural platform capable of supporting loads. The integration of these materials results in a floor system that is lightweight yet possesses substantial strength and rigidity. The primary purpose of using composite floor decks is to enhance structural performance while allowing for faster construction processes and reduced material costs.

The Role of Forming Machines

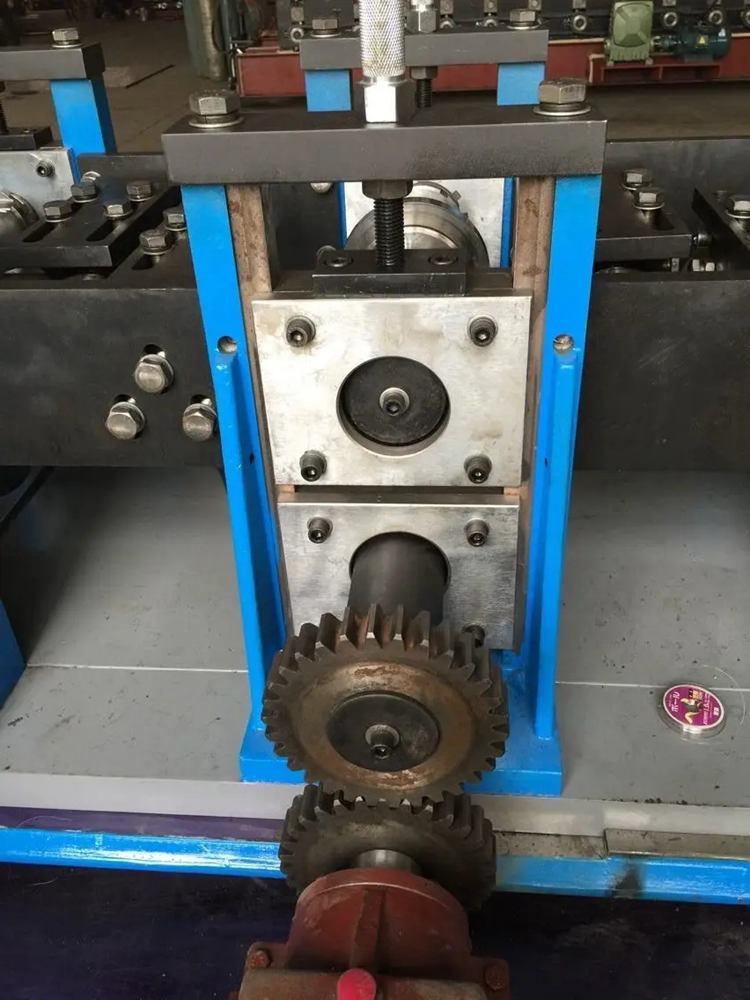

Composite floor deck forming machines automate the production of these essential components. These machines are designed to create profiles that facilitate the efficient uptake of concrete, ensuring that the composite system performs as intended. The forming process involves shaping metal sheets—often steel—into specific configurations that improve the bonding between the concrete and steel. This is vital for the overall strength and integrity of the floor system.

Modern forming machines come equipped with advanced technologies such as CNC (Computer Numerical Control) systems, which guarantee precision in the manufacturing process. This level of automation allows for quick adjustments to meet various project specifications, leading to customized production of floor decks that suit specific building requirements.

Advantages of Composite Floor Deck Forming Machines

1. Increased Efficiency One of the most significant advantages of using composite floor deck forming machines is the remarkable increase in production efficiency. By automating the forming process, manufacturers can produce large quantities of floor decks in significantly less time than traditional methods would permit.

2. Cost-Effectiveness The reduction in labor costs and the minimization of material waste contributes to a more cost-effective production process. Furthermore, the lightweight nature of composite decks leads to lower shipping expenses and simplifies the installation process on-site.

3. Enhanced Quality Control With the integration of advanced technologies, composite floor deck forming machines offer superior quality control compared to manual production methods. Manufacturers can adhere to strict tolerances and specifications, ensuring that every unit meets the required standards for safety and performance.

4. Sustainability The construction industry is increasingly moving towards sustainable practices, and composite floor deck forming machines support these initiatives. The efficient use of materials and reduction of waste not only lower the environmental impact but also align with green building practices. Additionally, the longevity and durability of composite materials contribute to a more sustainable lifecycle for buildings.

5. Flexibility and Customization Different construction projects may demand unique specifications, and modern forming machines can easily adapt to produce various designs. This flexibility means that manufacturers can cater to diverse architectural styles and structural requirements without compromising on production speed.

Impact on the Construction Industry

The advent of composite floor deck forming machines represents a paradigm shift in construction methodologies. As the demand for more efficient and sustainable construction solutions continues to rise, these machines provide valuable support to builders and developers. The construction landscape is increasingly characterized by its reliance on technology, with composite floor deck forming machines serving as a vital tool in meeting the industry's evolving needs.

Moreover, as urbanization accelerates and the need for new buildings grows, the ability to produce composite floor decks quickly and efficiently allows for faster project completions, enabling developers to respond promptly to market demands.

Conclusion

Composite floor deck forming machines are at the forefront of modern construction technology, driving significant improvements in efficiency, quality, and sustainability. As the construction industry continues to embrace innovation, these machines are set to play an even more critical role in shaping the future of how we build. By enhancing the production process and allowing for greater flexibility, composite floor deck forming machines not only streamline construction projects but also contribute to a more sustainable and cost-effective building industry.