Understanding Composite Floor Deck Cold Bending Machines

In the realm of modern construction, efficiency and precision are paramount. As architectural designs become more complex and the demand for innovative building materials increases, cold bending machines have emerged as essential tools in the fabrication of composite floor decks. These machines streamline the process of shaping high-strength materials, ensuring that structural components meet the rigorous standards required for safety and durability.

What is a Composite Floor Deck?

A composite floor deck is a combination of a metal deck with concrete, designed to enhance load-bearing capacity and provide a stable platform for various construction activities. This type of flooring system is widely used in commercial buildings, parking structures, and industrial facilities due to its lightweight properties and structural efficiency. The composite nature of the floor deck allows it to take advantage of both steel's tensile strength and concrete's compressive strength, resulting in a robust and cost-effective solution.

The Role of Cold Bending Machines

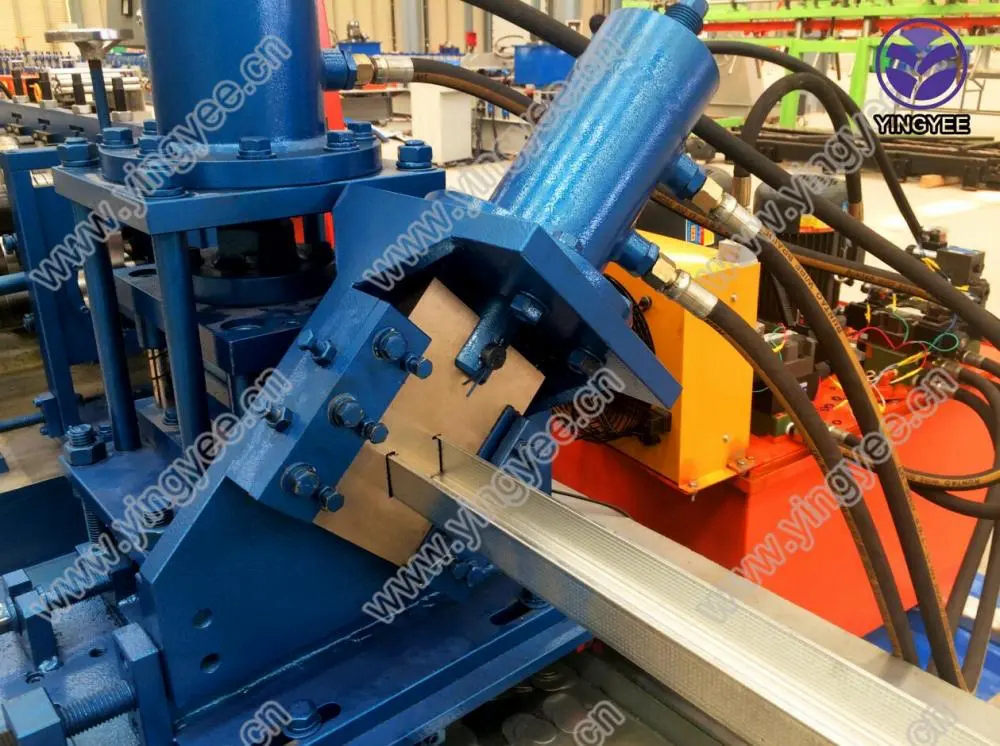

Cold bending machines play a crucial role in the production of composite floor decks. These machines are designed to apply force to structural materials, bending them without the application of heat. This method preserves the integrity of the steel and ensures that the metal retains its original strength, unlike hot bending techniques that can alter material properties.

The cold bending process involves a series of rollers that gradually shape the steel into the desired configuration. The precision of these machines enables manufacturers to create complex profiles that cater to diverse architectural requirements. This flexibility is vital for the construction industry, where customized solutions are often needed to meet specific project criteria.

Advantages of Using Cold Bending Machines

One of the primary advantages of cold bending machines is their ability to enhance production efficiency. They allow for quick adjustments in the bending process, enabling manufacturers to switch between different profiles with minimal downtime. This adaptability is essential in fast-paced environments where project timelines are strict.

Moreover, cold bending equipment typically operates with a high degree of accuracy, reducing material waste. By ensuring that each piece is made to precise specifications, manufacturers can optimize their resources, leading to cost savings and promoting sustainable practices in the industry. Additionally, the use of cold bending machines often results in less physical strain on workers, as the machines handle the heavy lifting and shaping processes, improving workplace safety.

Technological Innovations in Cold Bending Machines

Recent advancements in technology have also revolutionized cold bending machines. Modern models often incorporate computer numerical control (CNC) systems, which allow for automated and highly precise operations. These innovations ensure consistent quality across production runs and enable complex designs that would be difficult or impossible to achieve through manual methods.

Furthermore, the integration of software solutions helps manufacturers simulate bending processes before actual fabrication begins. This capability allows engineers to predict potential issues and optimize designs in a virtual environment, significantly reducing the chances of costly mistakes during production.

Conclusion

In conclusion, composite floor deck cold bending machines are vital assets in the modern construction industry. They not only enhance the efficiency and precision of manufacturing processes but also contribute to the overall structural integrity of buildings. As technology continues to advance, these machines will likely become even more sophisticated, enabling manufacturers to meet the evolving demands of architects and builders. By investing in cold bending technology, the construction industry can enhance its productivity while ensuring that safety and quality remain at the forefront of building design. This balance will be crucial as we move towards more innovative and sustainable construction practices in the future.