Understanding Composite Floor Deck Cold Bending Machinery Innovations and Applications

In modern construction, efficiency and strength are paramount. One innovative solution that has gained traction in recent years is the composite floor deck cold bending machine. This machinery plays a critical role in the fabrication of high-performance floor systems that offer both structural integrity and cost-effectiveness. This article explores the workings, benefits, and applications of composite floor deck cold bending machines.

What is Composite Floor Decking?

Composite floor decking consists of a combination of metal and concrete, typically utilizing galvanized steel and reinforced concrete. This system is designed to provide excellent load-bearing capabilities while minimizing weight. The advantages of composite floor decks become evident in multi-story buildings, where reducing the overall load can result in significant material and cost savings during construction.

The Importance of Cold Bending

Cold bending is a process that involves shaping materials at room temperature without the need for heating. This method is particularly beneficial for metal components used in construction, as it maintains the structural integrity of the material, preventing alterations in strength or microstructure that can occur with traditional hot bending methods.

Cold bending machines are specifically designed to achieve precise bends in steel sheets, enabling the fabrication of custom profiles that fit specific architectural and structural requirements. This technique is not only efficient but also enhances the overall durability and flexibility of composite floor systems.

How Composite Floor Deck Cold Bending Machines Operate

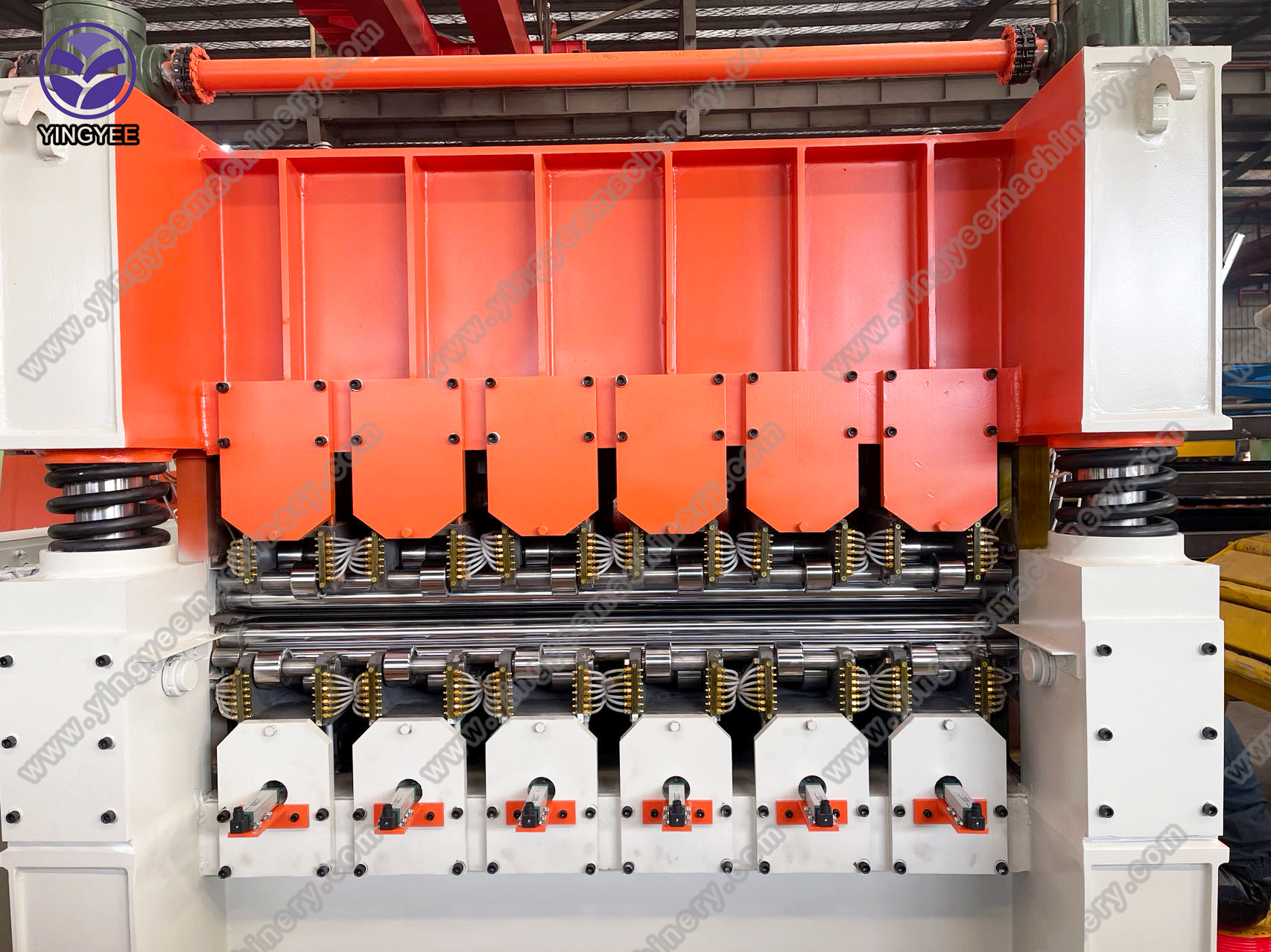

The operation of a cold bending machine involves several key components that work together seamlessly. Initially, steel sheets are fed into the machine, where they are positioned and aligned using advanced computer numerical control (CNC) technology. This ensures that the bends are executed with precision.

Once the material is securely in place, the machine applies force through rollers or press brakes, gradually shaping the steel into the desired profile. This process allows for various configurations, accommodating diverse architectural designs. The entire operation is monitored and adjusted in real-time, ensuring high-quality output while minimizing waste.

Benefits of Using Cold Bending Machines

1. Cost Efficiency By utilizing cold bending, manufacturers can reduce labor costs and material waste. The ability to create complex shapes with minimal effort streamlines the production process.

3. Customization The adaptability of cold bending machines allows for tailor-made solutions, accommodating various designs that clients may require in their projects.

4. Speed The automation involved in modern cold bending machines enhances speed, enabling quicker turnaround times for construction projects.

Applications in Construction

Composite floor deck cold bending machines find applications in various sectors of construction. From commercial buildings to industrial complexes, the versatility of the composite floor decking system meets diverse requirements for structural frameworks.

In the commercial sector, retail spaces and office buildings benefit from the aesthetic appeal and functional performance of composite floors. Additionally, industrial applications, where high load-bearing capabilities are essential, rely on these systems for safety and stability.

Moreover, ongoing innovations in materials science and engineering continue to enhance the performance of composite floor decking. As sustainable building practices become more critical, composite solutions provide an environmentally friendly alternative by using recyclable materials and optimizing resource consumption.

Conclusion

Composite floor deck cold bending machinery represents a significant advancement in construction technology. By combining efficiency, strength, and customization capabilities, this machinery is reshaping the way buildings are designed and constructed. With the ever-evolving landscape of the construction industry and the increasing focus on sustainability, these machines will undoubtedly play a pivotal role in the future of structural engineering. As builders and architects seek innovative solutions to meet modern demands, the importance of composite floor deck cold bending machines will continue to grow.