Competitive Price Steel Cable Tray Roll Forming Machine

In today's rapidly evolving industrial landscape, the demand for efficient, high-quality manufacturing solutions has never been more pronounced. One such solution that has gained significant traction is the steel cable tray roll forming machine. This equipment not only enhances production efficiency but also ensures the creation of sturdy and reliable cable trays that are integral to modern electrical installations. The competitive pricing of these machines has made them accessible to a broader range of businesses, thus contributing to their popularity across multiple sectors.

Understanding Cable Trays and Their Importance

Cable trays are essential components used in a variety of electrical and telecommunication systems. They support and manage electrical wiring, ensuring safety and organization within industrial settings, commercial buildings, and infrastructures. As industries expand and technology advances, the need for reliable cable management systems continues to grow. This heightened demand drives the necessity for advanced machinery capable of producing high-quality cable trays at competitive prices.

The Role of Roll Forming Machines

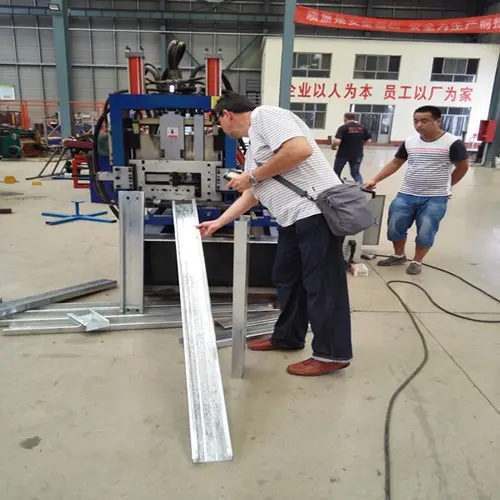

Roll forming machines are specialized equipment designed to process metal sheets into predefined shapes through a continuous bending operation. The steel cable tray roll forming machine specifically tailors this process to manufacture cable trays in various sizes and configurations. Utilizing dedicated die sets and roll components, these machines enable the production of trays with precise dimensions, ensuring compatibility with various structural layouts and electrical configurations.

Advantages of Steel Cable Tray Roll Forming Machines

1. Cost-Effectiveness One of the most significant advantages of steel cable tray roll forming machines is their competitive pricing. Companies can invest in these machines without straining their budgets, leading to a faster return on investment. The affordability of these machines has made them accessible to both large-scale manufacturers and smaller businesses looking to expand their capabilities.

2. Efficiency The roll forming process is inherently efficient, allowing for mass production of cable trays with minimal waste. This efficiency not only speeds up the manufacturing process but also helps businesses reduce operational costs. With the ability to produce large volumes in a short timeframe, manufacturers can meet market demands promptly.

3. Quality Control Modern roll forming machines are equipped with advanced technology that ensures high precision and quality in production. This automation minimizes human error and maintains consistent quality standards, which are crucial in the manufacturing of electrical components that must meet stringent safety regulations.

4. Versatility Steel cable tray roll forming machines can produce trays of various designs, including ladder-type, perforated, and solid bottom. This versatility enables manufacturers to cater to diverse customer needs and adapt to market changes rapidly.

5. Durability and Strength Steel as a material offers exceptional durability and strength, which are paramount for cable trays meant to support heavy electrical loads. The roll forming process enhances these properties, resulting in trays that are both robust and reliable.

Future Prospects

As the demand for efficient electrical management systems continues to rise, the market for steel cable tray roll forming machines is poised for growth. Innovations in technology and manufacturing processes promise to further reduce costs while improving efficiency and product quality. Companies adopting these machines can expect not only to enhance their production capabilities but also to gain a competitive edge in the market.

In conclusion, the steel cable tray roll forming machine represents a vital investment for businesses looking to thrive in the electrical manufacturing sector. With their competitive pricing, efficiency, versatility, and ability to ensure high-quality production, these machines are becoming indispensable. As industries evolve, the role of such equipment will only become more pronounced, facilitating the growth and development of modern infrastructure while meeting the ever-increasing demand for reliable cable management solutions. For those looking to streamline operations and improve product quality, investing in a steel cable tray roll forming machine is a smart choice that offers both immediate benefits and long-term advantages.