The Competitive Pricing of Steel Cable Tray Roll Forming Machines

In the fast-paced and demanding world of industrial manufacturing, efficiency and cost-effectiveness often dictate the success of a business. Among the critical components in electrical and communication infrastructures are steel cable trays, which support and protect cables. The manufacturing of these trays often hinges on advanced machinery, particularly roll forming machines. Among these, steel cable tray roll forming machines have gained significant attention due to their efficiency and versatility, and reasonable pricing has become paramount in attracting businesses.

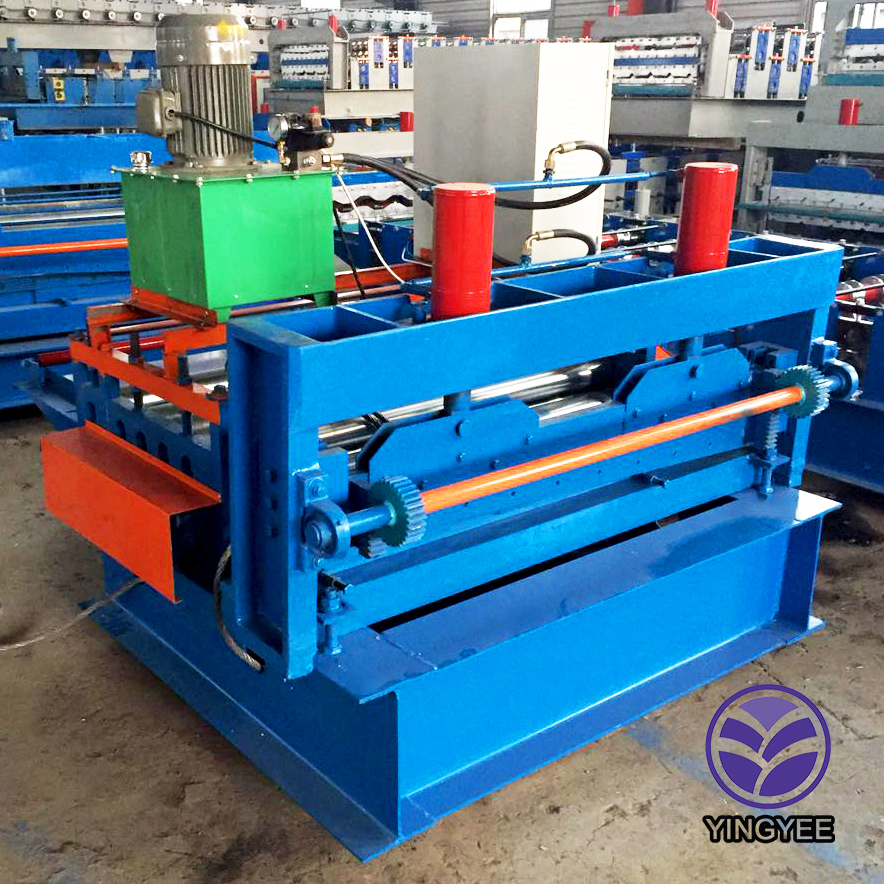

The process of roll forming is a continuous bending operation in which long strips of metal, usually steel, are gradually shaped into specific profiles. Steel cable tray roll forming machines are engineered to shape metal sheets into trays that can carry electrical cables, ensuring safety and organization in various installations, from commercial buildings to industrial plants. These machines can produce trays of various sizes, shapes, and thicknesses, catering to diverse customer requirements.

One of the most significant advantages of investing in a steel cable tray roll forming machine is the competitive pricing available in today’s market

. Manufacturers around the globe are recognizing the demand for these machines and have ramped up production, leading to increased competition. This competition has driven prices down, making it feasible for even small and medium-sized enterprises to invest in advanced manufacturing technology.

Moreover, modern steel cable tray roll forming machines are designed with efficiency in mind. These machines often feature automated systems that reduce human labor, lower production time, and minimize material waste. By integrating advanced technology, manufacturers can achieve high output while maintaining lower operational costs. The ability to produce high volumes at lower costs makes these machines immensely appealing to businesses looking to optimize their production line.

Additionally, the pricing of steel cable tray roll forming machines is influenced by the materials used, technological advancements, and customizations. Basic models may be more affordable, while machines with advanced features such as programmable logic controllers (PLCs), touch-screen interfaces, and enhanced safety features will come at a higher price. However, the long-term benefits gained from these features, including reduced downtime and better product quality, often outweigh the initial investment cost.

In the global market, sourcing these machines at competitive prices also means exploring manufacturing hubs in different regions. Countries like China and Germany have established themselves as leaders in the production of roll forming technology, offering a range of options to meet various budgets and specifications. Businesses can choose to import machines that best fit their operational needs while remaining cost-efficient.

In conclusion, steel cable tray roll forming machines are integral to the effective manufacture of cable management solutions. With competitive pricing driven by increased competition and technological advancements, businesses of all sizes can invest in this essential equipment. As the industry continues to evolve, it is essential for manufacturers to stay informed about market trends and technological innovations to maximize their investment in roll forming machinery. By leveraging these advantages, companies can remain competitive, improve their operational efficiency, and ensure the growth of their enterprises in an ever-changing manufacturing landscape.