The Evolution and Importance of Color Steel Sheet Shutter Door Forming Machines

In the contemporary landscape of construction and architectural innovation, the demand for efficiency, durability, and aesthetic appeal in building materials is more significant than ever. One of the critical advancements in this area is the development of color steel sheet shutter door forming machines. These machines have revolutionized the manufacturing process of door systems, enhancing both functionality and design.

What are Color Steel Sheet Shutter Doors?

Color steel sheet shutter doors, often referred to as roller shutters, are constructed using pre-painted galvanized steel sheets. This material is lightweight yet robust, making it ideal for high-security applications in commercial and industrial settings. The vibrant colors add a layer of aesthetic appeal, enhancing the building's overall exterior. These doors are widely used in shopping malls, warehouses, garages, and other facilities requiring secure and efficient door systems.

The Forming Process

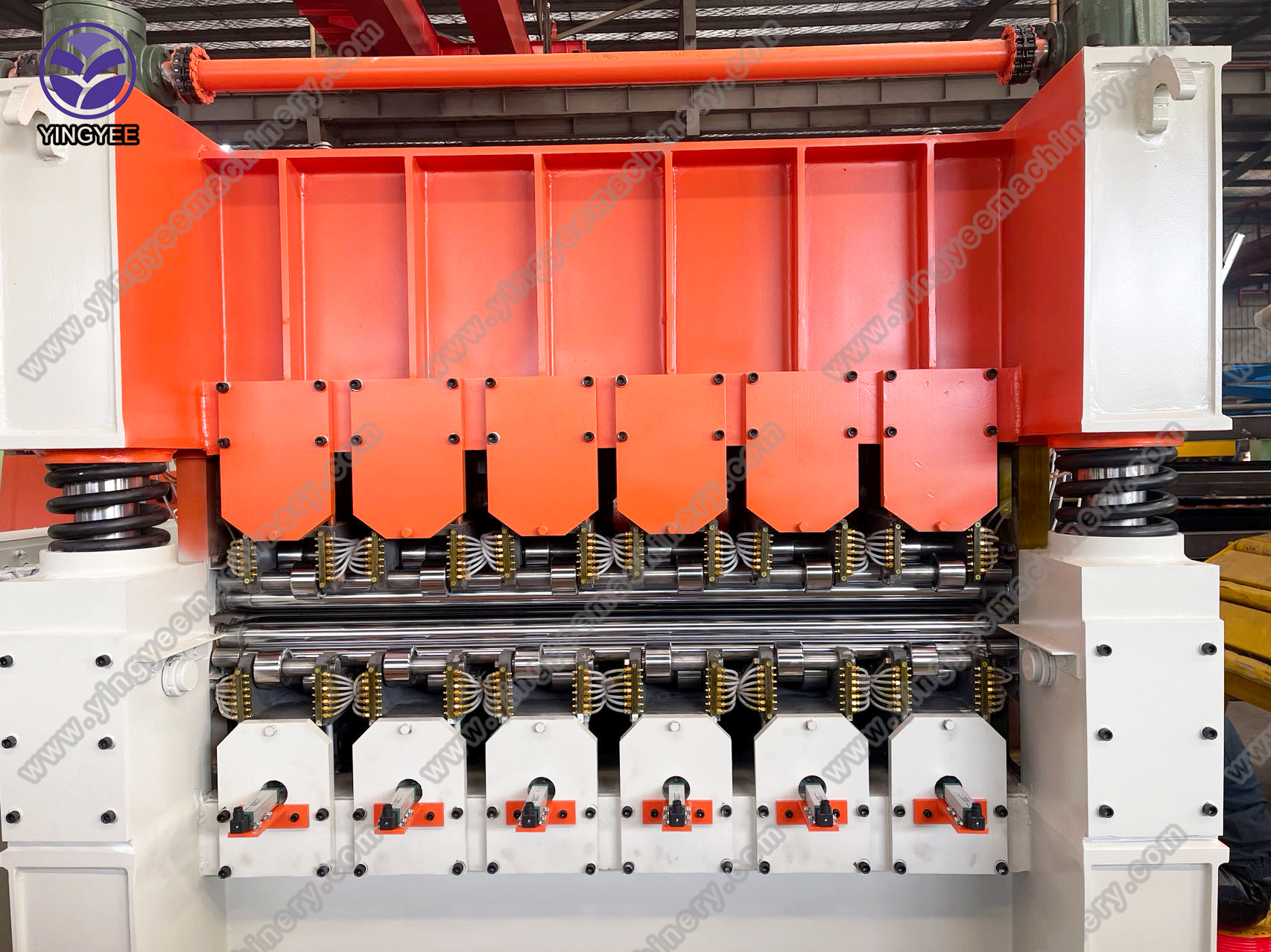

The core of the production of color steel sheet shutter doors lies in the forming machine. These advanced machines are capable of converting raw color steel sheets into intricately designed, durable shutter doors through a precision process that involves several stages. Initially, the metal sheets are fed into the machine, where they undergo various shaping and forming procedures.

1. Cutting The process starts with the cutting of metal sheets to the desired length, ensuring consistency and precision in dimension, which is essential for the functionality of the doors.

2. Roll Forming The cut sheets are then fed into a roll forming system, where they are passed through a series of rollers. These rollers progressively shape the sheet into the desired profile, giving it strength and rigidity.

3. Lacquering Depending on the design specifications, the doors can go through a lacquering process where additional coats of paint or protective layers are applied. This not only enhances the aesthetic aspect but also ensures the longevity of the door against environmental factors.

4. Punching and Cutting Openings For various functionalities, such as ventilation or access points, the shutter doors may require specific openings or punch-outs. This process is executed with precision to avoid any compromise in the structural integrity of the door.

5. Final Assembly Finally, the formed parts are assembled into complete shutter door systems, ready for installation. This holistic approach streamlines the manufacturing process and allows for custom solutions tailored to specific client needs.

Benefits of Color Steel Sheet Shutter Door Forming Machines

The use of color steel sheet shutter door forming machines confers several advantages that make them an attractive option for manufacturers

- Efficiency These machines automate the production process, significantly reducing labor costs and production time. With their high-speed capabilities, manufacturers can meet increasing market demands without compromising on quality.

- Versatility The machines can be customized to produce various styles and sizes of shutter doors, catering to diverse customer preferences and requirements.

- Durability Color-coated steel sheets are known for their exceptional resistance to corrosion, fading, and wear, drastically extending the life of the doors produced.

- Aesthetic Value The availability of various colors and finishes allows for endless design possibilities, enabling businesses to create visually appealing products that can complement the architectural styles of different buildings.

Conclusion

As the construction and architectural sectors continue to evolve, so too do the technologies that support them. Color steel sheet shutter door forming machines exemplify this advancement, offering a combination of efficiency, durability, and aesthetic flexibility. As businesses strive to meet modern safety and design standards, adopting such innovative machinery becomes essential. This not only leads to improved product offerings but ultimately enhances customer satisfaction, driving overall growth in the industry. The future of construction lies in embracing these technological innovations, and with color steel sheet shutter door forming machines at the forefront, that future looks promising.