The Color Steel Sheet Shutter Door Forming Machine Revolutionizing Industry Standards

In today's fast-paced industrial world, efficiency and customization are paramount. One of the significant technological advancements that have emerged to meet these demands is the color steel sheet shutter door forming machine. This incredible piece of machinery not only enhances production capacity but also ensures high-quality output tailored to specific customer needs.

Understanding the Machine

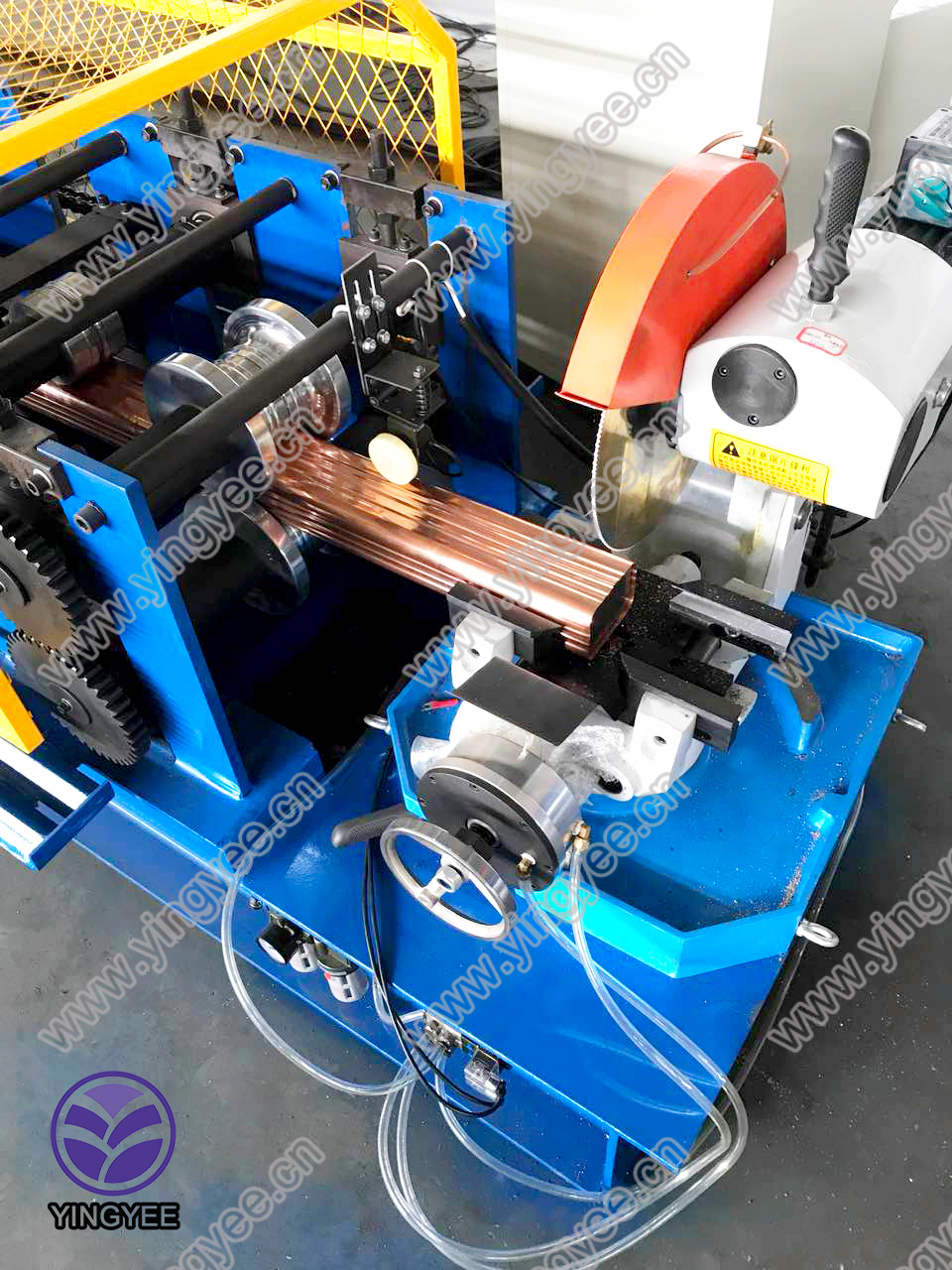

The color steel sheet shutter door forming machine is designed for the efficient production of rolling shutter doors that are commonly used for commercial establishments, warehouses, and even residential properties. This machine operates by converting plain steel sheets into various profiles and shapes with the help of advanced forming techniques. The term color steel refers to pre-painted steel sheets that offer both durability and aesthetic appeal, making them an ideal choice for use in environments where visibility and appearance matter.

The forming process typically involves several key steps, including unwinding, feeding, roll forming, and cutting the steel sheets to the desired length. The machine's rollers shape the steel into the required configuration, while powerful hydraulic or electric systems ensure that the output is seamless and consistent. Additionally, many of these machines come equipped with cutting-edge technology, including digital displays and automated controls, allowing for user-friendly operation and precision in production.

Benefits of Using a Color Steel Sheet Shutter Door Forming Machine

1. Durability and Strength Color steel sheets are known for their resilience against corrosion and environmental factors. When manufactured into shutter doors, they offer extended operational life and require minimal maintenance. This makes them a cost-effective solution for businesses looking to invest in long-term infrastructure.

2. Aesthetic Versatility Available in a multitude of colors and finishes, color steel sheet shutter doors can easily complement the architectural design of any building. Business owners can choose from various styles that reflect their brand identity and create a welcoming atmosphere for customers.

3. Customization The modern forming machines allow for a high degree of customization. Manufacturers can produce doors in different sizes, profiles, and designs, catering to unique specifications from clients. Whether it’s for a small retail shop or a large industrial facility, the versatility of these machines meets a wide range of requirements.

4. High Efficiency The automated nature of the forming machine significantly reduces production times. High-speed operations enable manufacturers to meet large order demands quickly without sacrificing quality. As a result, businesses can maintain supply chain efficiency and customer satisfaction.

5. Environmental Considerations Many color steel sheet shutter door forming machines are designed with sustainability in mind. They can minimize waste during production processes and utilize materials that are more environmentally friendly, thus contributing to green manufacturing efforts.

Conclusion

The color steel sheet shutter door forming machine stands as a testament to the advancements in manufacturing technology. By combining durability, aesthetic appeal, and operational efficiency, it has become a go-to solution for industries requiring reliable shutter door systems.

Investing in such machinery not only helps manufacturers meet the ever-increasing demand for customized products but also positions them at the forefront of innovation within their respective markets. As industries continue to evolve, embracing technologies like the color steel sheet shutter door forming machine is essential for staying competitive and meeting customer expectations effectively.

In summary, the integration of color steel sheet shutter door forming machines into production lines can dramatically enhance a company's capabilities, allowing it to thrive in an increasingly competitive environment. The future holds great potential for further technological advancements in this area, promising even greater efficiency and quality in manufacturing processes to come.