Cold Standing Seam Making Machine Revolutionizing Metal Roofing

In the world of modern construction, the demand for durable and efficient roofing solutions has never been higher. One innovation that has gained traction in recent years is the cold standing seam making machine. This advanced technology is transforming the way metal roofs are constructed, offering a host of benefits that cater to both builders and homeowners.

A cold standing seam roof is characterized by its vertical panels and interlocking seams, which are not only aesthetically appealing but also provide exceptional weather resistance. Traditional roofing methods often involve hot-seaming processes, which can be labor-intensive and time-consuming. In contrast, cold standing seam machines streamline the manufacturing process by allowing for precise cuts and folds at room temperature. This not only simplifies the installation process but also enhances the structural integrity of the roof.

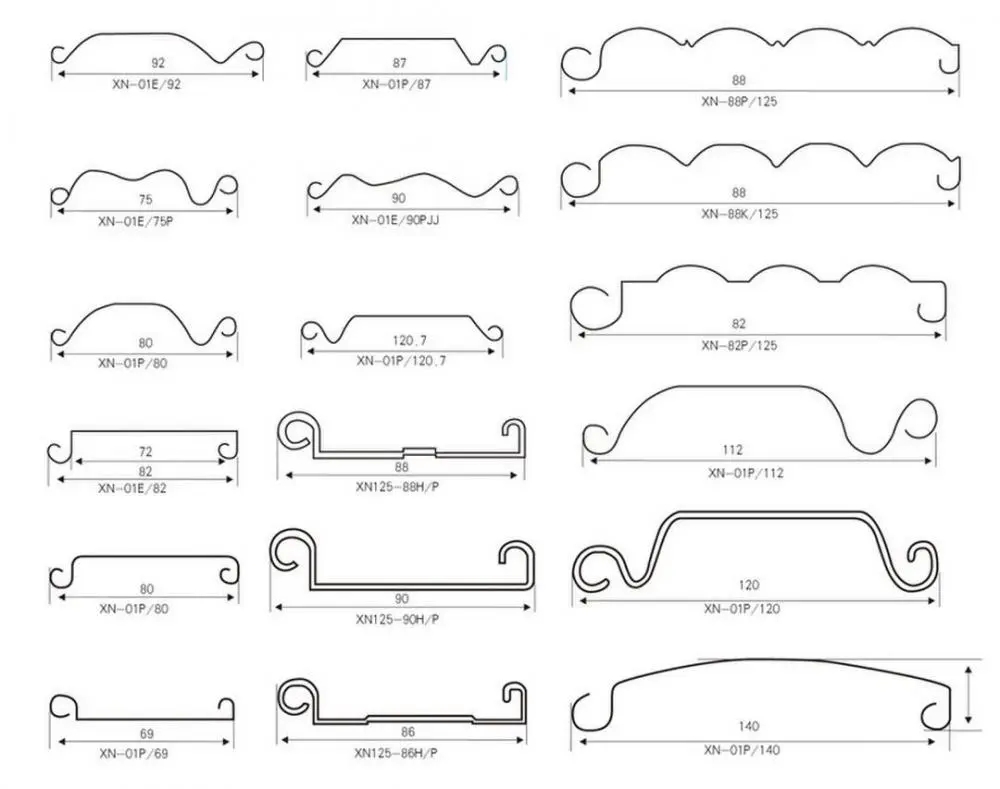

The primary function of a cold standing seam making machine is to create metal panels that are custom-fitted to the specifications of the project

. These machines are equipped with advanced technology that allows them to produce panels of various lengths and widths, ensuring that they meet the unique needs of any roofing job. This customization is essential in today’s construction environment, where every project is different, and the need for flexibility is paramount.

One of the key advantages of using a cold standing seam making machine is the reduction of material waste. Traditional seaming methods often result in scraps and unusable pieces of metal, leading to higher costs and environmental concerns. In contrast, these machines optimize their processes to minimize waste, making them more cost-effective and environmentally friendly.

Moreover, the durability of cold standing seam roofs is remarkable. The interlocking design means that they are less susceptible to leaks and water penetration, a common issue in traditional roofing systems. Additionally, the materials used in these roofs, such as aluminum and galvanized steel, provide excellent resistance against corrosion and weather-related damage. This durability translates into longer-lasting roofing solutions and reduced maintenance costs for homeowners.

From an operational standpoint, cold standing seam making machines are user-friendly, which reduces the learning curve for new operators. With clear interfaces and automated features, workers can efficiently produce high-quality roofing panels with minimal training. This efficiency not only speeds up the construction process but also improves overall project timelines.

In conclusion, cold standing seam making machines are at the forefront of modern roofing technology. They provide builders with the ability to create customized, high-quality metal roofing solutions that are both durable and efficient. As the construction industry continues to evolve, the adoption of such innovative technologies will likely play a crucial role in meeting the demands for sustainable building practices and improved architectural designs. By embracing these advancements, builders can deliver superior roofing solutions that stand the test of time.