Cold Standing Seam Making Machine Revolutionizing Metal Roof Production

In the world of construction and architecture, the importance of durable and aesthetically appealing roofing cannot be overstated. Among the various roofing techniques, standing seam metal roofs have gained significant popularity because of their functionality, longevity, and sleek appearance. A pivotal component in creating these roofs is the cold standing seam making machine, a technology that is transforming the metal roofing industry.

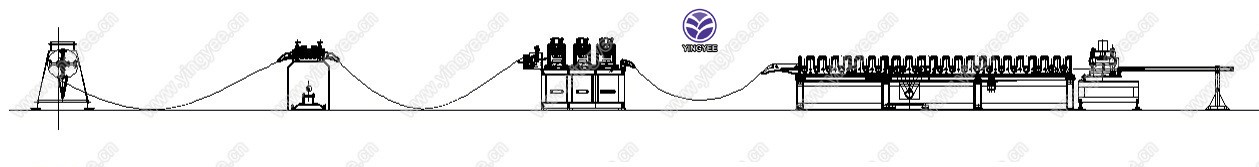

The cold standing seam making machine is designed to produce standing seams by cold-forming metal sheets without the need for heat, allowing for better control over the material properties. This process is particularly advantageous as it minimizes the risk of warping or altering the metal's integrity, which is crucial for maintaining strength and durability. By employing cold-forming techniques, manufacturers can produce seams that offer superior performance against the elements, including rain, snow, and wind.

One of the primary benefits of using a cold standing seam making machine is its efficiency. These machines can produce high volumes of metal panels in a relatively short amount of time. By automating the seam-making process, manufacturers reduce labor costs and material waste, which ultimately leads to more sustainable production practices. Furthermore, with consistent quality control, the machine ensures that each seam adheres to precise specifications, leading to an enhanced final product.

Additionally, the versatility of cold standing seam machines allows for the customization of panel sizes and profiles, meeting the diverse needs of various architectural designs. Whether for residential projects or large commercial buildings, these machines can easily adapt to different material types and thicknesses, providing architects and builders with the flexibility they require.

Moreover, the standing seam system is renowned for its ability to expand and contract with temperature fluctuations, thanks to the concealed fasteners used in the installation. This characteristic greatly reduces the risk of leaks and enhances the roof's overall durability. The cold standing seam making machine is integral in creating these resilient connections, ensuring the longevity and reliability of the roofing system.

In conclusion, the cold standing seam making machine plays a vital role in the evolution of metal roofing. By combining efficiency, quality control, and versatility, this technology not only streamlines production processes but also contributes to the creation of robust and visually appealing roofing solutions. As the demand for sustainable and durable building materials continues to grow, the cold standing seam making machine is poised to remain at the forefront of innovation in the construction industry.