Cold Roll Roof Forming Machine Revolutionizing Roof Construction

In the modern construction industry, efficiency, durability, and cost-effectiveness are paramount. A critical innovation that has emerged to meet these demands is the cold roll roof forming machine. This advanced equipment plays a vital role in producing high-quality roofing sheets with unmatched precision and speed.

What is a Cold Roll Roof Forming Machine?

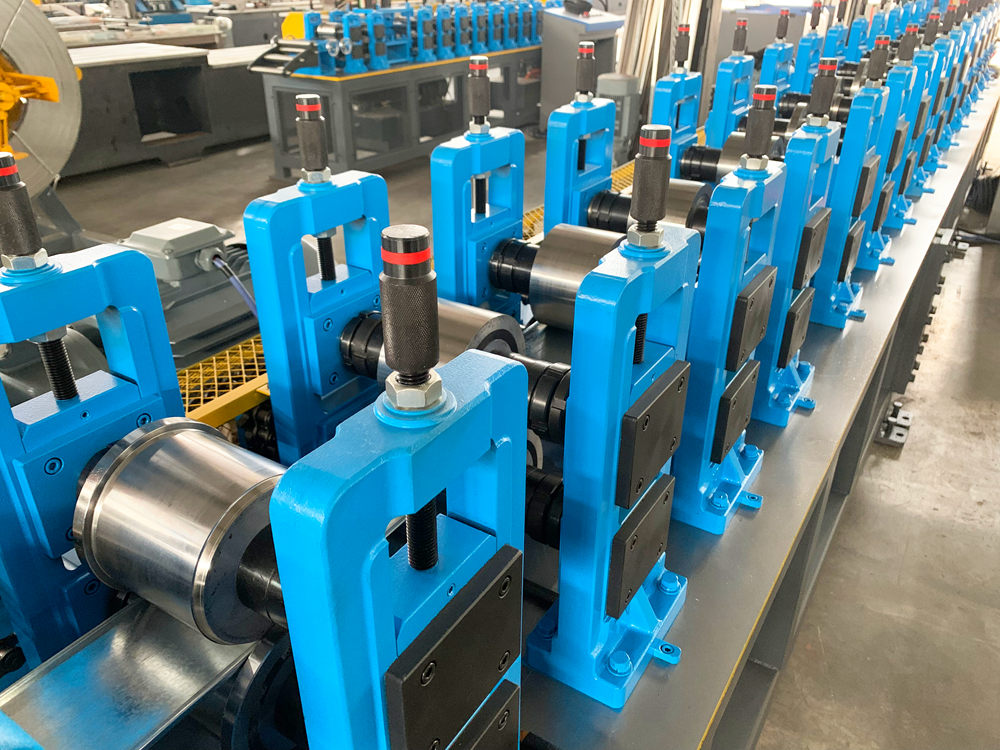

A cold roll roof forming machine is a type of industrial machinery designed to create roofing panels from metal coils

. Unlike traditional roofing methods, the cold rolling process shapes the metal at room temperature, which helps maintain the material's integrity and prevents structural weaknesses commonly associated with heat-based forming processes. These machines can produce a variety of profiles, including standing seam, corrugated, and tile-like designs, catering to diverse architectural needs.Key Features and Benefits

1. Efficiency and Speed One of the hallmark features of cold roll roof forming machines is their ability to produce roofing materials quickly. The automated process requires minimal human intervention, significantly reducing labor costs and time on site. This efficiency allows construction projects to proceed swiftly, meeting tight deadlines without sacrificing quality.

2. Cost-Effectiveness By utilizing raw materials effectively and minimizing waste, cold roll roof forming machines contribute to overall cost savings. The ability to produce roofing panels on-site from standard coils also decreases transportation expenses and the need for additional storage, further enhancing the economic viability of projects.

3. High Precision These machines are engineered to deliver consistent results, producing panels with precise dimensions and specifications. This precision is crucial in ensuring that roofing sheets fit perfectly during installation, reducing the risk of errors and the need for costly rework.

4. Variety of Designs Cold roll roofing machines can create various metal profiles, allowing for aesthetic versatility in construction. Whether for residential buildings, commercial enterprises, or industrial structures, these machines can adapt to produce the desired roofing style, enhancing the overall architectural appeal.

5. Durability and Sustainability Roofing produced using cold roll forming is typically made from high-grade metals like steel or aluminum, which are renowned for their longevity and resistance to harsh weather conditions. Additionally, many manufacturers are now focusing on sustainable practices, producing recyclable roofing materials that contribute to environmentally friendly building projects.

Conclusion

The cold roll roof forming machine represents a significant advancement in roofing technology, optimizing the production process while ensuring high-quality outcomes. Its efficiency, cost-effectiveness, precision, and design flexibility make it an invaluable asset in the modern construction landscape. As the industry continues to evolve, the adoption of such innovative machinery will likely increase, further enhancing the standards of roofing construction and paving the way for sustainable building practices. Embracing this technology not only streamlines construction processes but also contributes to the creation of roofs that stand the test of time.