Understanding Cold Bending Prices Factors and Trends

Cold bending is a manufacturing process that involves the deformation of materials at room temperature. This technique is notably utilized in shaping metals, particularly in the construction and manufacturing industries. When evaluating the costs associated with cold bending, various factors play a significant role. Understanding these factors helps businesses make informed decisions regarding their projects and budgeting.

Material Costs

The first aspect influencing cold bending prices is the type of material being used. Common materials include steel, aluminum, copper, and various alloys. Steel, being the most widely used material in construction, can vary significantly in price depending on its grade and supply chain dynamics. For example, the ongoing fluctuations in the steel market, driven by global demand, tariffs, and trade agreements, can directly impact the cost of cold bending services. Meanwhile, aluminum tends to be more expensive due to its lightweight and corrosion-resistant properties, making it desirable for specific applications.

Complexity of Design

The complexity of the design also plays a crucial role in determining cold bending prices. Simple shapes and bends may incur lower costs since they require less specialized machinery and labor. Conversely, intricate designs demand higher precision, which often necessitates advanced tooling and skilled labor. Companies may need to invest in custom molds or technologies to achieve the desired results, increasing the overall cost of the project. Therefore, it is essential for clients to consider the intricacies of their designs when budgeting for cold bending services.

Production Volume

Production volume is another critical factor that can influence cold bending prices. For instance, large-scale projects often benefit from economies of scale. When a manufacturer can produce items in bulk, the cost per unit generally decreases due to more efficient use of resources and reduced labor costs per item. Conversely, smaller production runs will likely face higher per-unit costs. Clients should assess their quantity needs and discuss potential pricing structures with suppliers to find the best value for their projects.

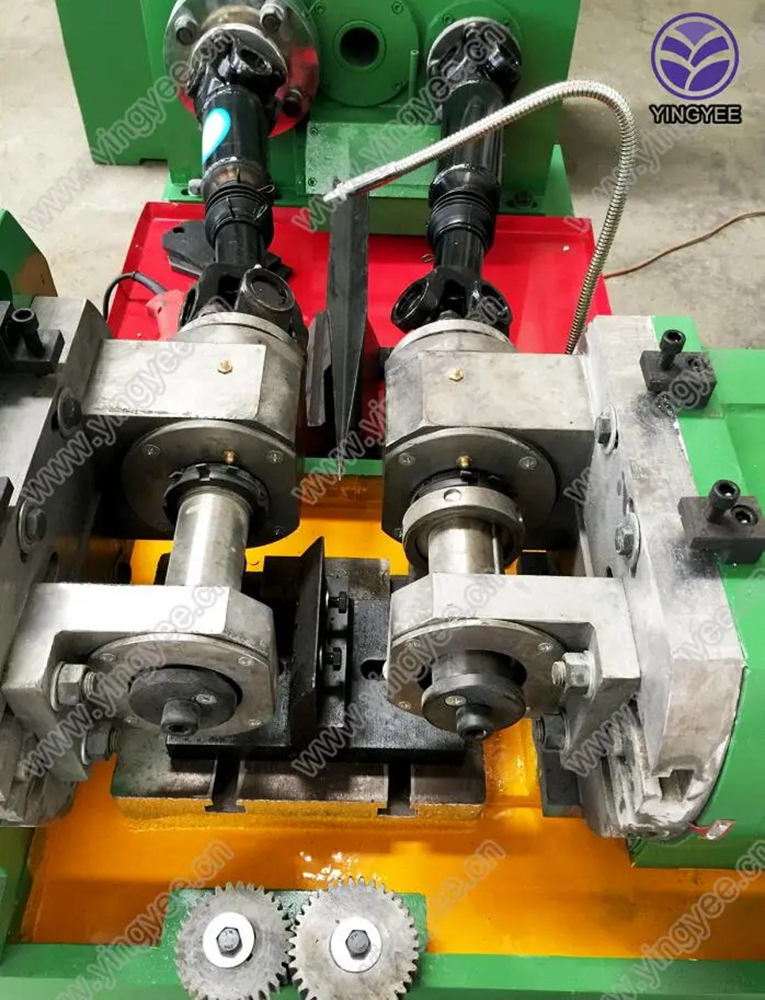

Equipment and Technology

The technology and equipment used in the cold bending process can significantly affect prices. Advanced machinery can lead to more precise bends and cuts, enhancing the overall quality of the finished product. However, the cost of investing in such technology may also be reflected in the service charges. Companies that utilize state-of-the-art equipment may charge a premium but offer better quality and efficiency, which could save clients money in the long run through reduced waste and rework.

Labor Costs

Labor costs are another vital consideration when evaluating cold bending prices. Skilled labor is necessary to operate specialized machinery and ensure accuracy in bending processes. In regions where labor is scarce or wages are high, or in industries experiencing labor shortages, these costs can spike. Businesses should consider these variables when planning projects, particularly if there’s a variation in labor availability and costs in their respective regions.

Market Trends

Finally, broader market trends can impact cold bending prices. Changes in demand for construction, manufacturing output, and even economic conditions can all lead to fluctuations in prices. For example, a booming construction industry may increase demand for cold-bent materials, leading to higher prices. Conversely, during economic downturns, prices may stabilize as demand wanes.

Conclusion

In conclusion, cold bending prices are influenced by a multitude of factors, including material costs, design complexity, production volume, equipment technology, labor costs, and market trends. To achieve the best outcomes for their projects, companies must navigate these variables thoughtfully. By considering these elements in their planning and budgeting stages, businesses can optimize their spending on cold bending services and secure better results in their manufacturing and construction endeavors. As industries continue to evolve, staying informed about these factors will be crucial for maintaining competitive pricing and quality in the marketplace.