The Importance of Truck Fender Cold Bending Machines

In the world of truck manufacturing and repair, efficiency and precision are paramount. One crucial piece of equipment that enhances both these aspects is the truck fender cold bending machine. This specialized machinery is designed to shape and form truck fender components with a high degree of accuracy, ensuring that the end products not only fit perfectly but also meet the stringent demands of durability and safety.

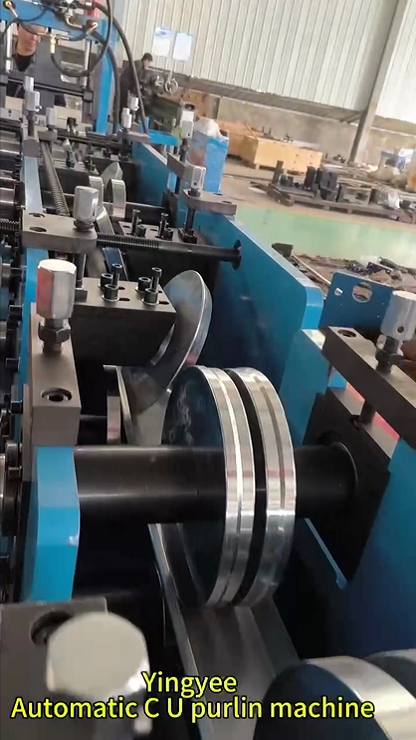

Understanding Cold Bending

Before delving into the importance of truck fender cold bending machines, it’s vital to understand the concept of cold bending. Cold bending refers to the process of shaping metal at room temperature, as opposed to hot bending, which involves heating the metal to make it more malleable. Cold bending preserves the material's strength and structural integrity, making it an ideal choice for automotive components where resilience and longevity are critical.

Advantages of Truck Fender Cold Bending Machines

1. Precision Manufacturing One of the most significant advantages of using cold bending machines in truck fender production is the precision they offer. These machines can produce highly accurate bends and shapes, ensuring that each fender fits perfectly onto the truck. This precision minimizes the risk of errors in assembly, which can lead to costly rework or part replacement.

2. Enhanced Material Strength Cold bending not only retains the original properties of the metal but can also enhance its strength through work hardening. This is particularly beneficial for truck fenders, which must withstand significant wear and tear from both road conditions and external impacts. The durability of cold-bent components reduces the likelihood of damage and extends the overall lifespan of the truck.

3. Efficiency and Speed Truck fender cold bending machines are designed for high-throughput production. Their automated or semi-automated processes can significantly reduce the time required to create fender components. Quick turnaround times ensure that manufacturers can meet customer demands promptly, thus improving overall production schedules and business competitiveness.

4. Cost-Effective Production Investing in advanced cold bending technology allows manufacturers to reduce material waste significantly. Traditional bending methods often result in excess scrap metal, but cold bending maximizes material usage. Consequently, this translates into lower production costs while maintaining product quality.

5. Versatility Modern cold bending machines are designed to handle a variety of materials and shapes, making them versatile additions to any manufacturing facility. Whether working with different types of metals or producing fenders of varying sizes and designs, these machines can adapt quickly, providing manufacturers with the flexibility to meet diverse market needs.

Conclusion

Truck fender cold bending machines play a critical role in the manufacturing and repair of trucks, ensuring that fender components are not only accurately shaped but also durable and cost-effective. By leveraging the advantages of cold bending technology, manufacturers can improve their production efficiency while delivering high-quality products that meet industry standards. As the trucking industry continues to evolve, the importance of these machines will only grow, positioning them as invaluable assets in the world of automotive manufacturing.