Understanding the Guardrail Block Spacer Cold Bending Machine

In the realm of modern construction and road safety infrastructure, the significance of guardrails cannot be overstated. These barriers serve the crucial purpose of preventing vehicles from veering off roads, thereby enhancing safety for both drivers and pedestrians. One of the pivotal tools in the production of guardrails is the guardrail block spacer cold bending machine. This innovative piece of machinery plays a fundamental role in shaping the components required for durable and effective guardrail systems.

The Role of Guardrail Block Spacers

Before delving into the machine itself, it is important to understand the function of guardrail block spacers. These spacers are essential for ensuring that guardrails are installed correctly and maintain their integrity over time. They provide necessary gaps between guardrail sections, facilitating proper drainage and allowing for any thermal expansions or contractions that may occur. By using block spacers, engineers can enhance the longevity and resilience of the guardrail assemblies.

What is a Cold Bending Machine?

A cold bending machine is a specialized apparatus designed to bend metal profiles without the need for heating. This process allows for precise shaping of materials at room temperature, which is particularly advantageous in the production of guardrail components. The cold bending technique is known for preserving the physical properties of the metal, resulting in a more robust final product. This method also increases efficiency, as it reduces energy consumption typically associated with heating metals before bending.

Features of the Guardrail Block Spacer Cold Bending Machine

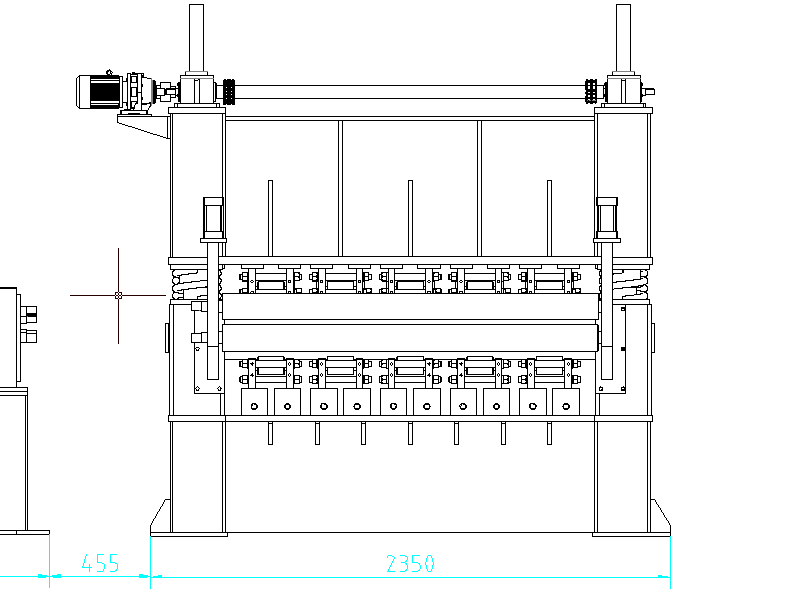

The guardrail block spacer cold bending machine is equipped with various features that enhance its productivity and precision. Typically, these machines come with a programmable control system that allows operators to input specific bending profiles. This automation ensures that each spacer is produced consistently and to exact specifications. Furthermore, many modern machines are designed with multiple bending stations, enabling the simultaneous processing of multiple pieces, which significantly speeds up production times.

Additionally, these machines often incorporate safety features, such as emergency stop buttons and protective covers, to safeguard operators during the bending process. The ability to handle various metal thicknesses and dimensions makes these machines versatile, accommodating different design requirements for guardrails.

Benefits of Utilizing Cold Bending Machines

The use of guardrail block spacer cold bending machines offers several advantages. Firstly, the precision achieved through automated controls results in high-quality components that meet rigorous safety standards. Secondly, the cold bending process minimizes the risk of material defects, such as warping or cracking, which can be common in hot bending processes.

Moreover, the efficiency gained through the use of these machines can lead to significant cost savings for manufacturers. With faster production cycles and reduced material waste, companies can enhance their profit margins while delivering quality products to their customers.

Conclusion

In conclusion, the guardrail block spacer cold bending machine represents a vital component in the production of modern road safety infrastructure. As the demand for reliable and effective guardrails continues to grow, the importance of advanced manufacturing technologies becomes ever more critical. By utilizing cold bending machines, manufacturers can ensure that they meet safety standards while also achieving efficiency and cost-effectiveness in their operations. The relationship between innovative machinery and infrastructure safety will remain a central focus as we look toward the future of transportation.